Vertical suction pump V2.0

Compatible models: myCobot 280, myPalletizer 260, mechArm 270

product icon

Specifications

| name | myCobot Vertical Suction Pump V2.0 |

|---|---|

| model | myCobot_suctionPump_V2.0_grey |

| Material | ABS injection molding |

| color | White |

| size | Suction pump box: 72x52x37 Suction pump end: 63x24.5x26.7 |

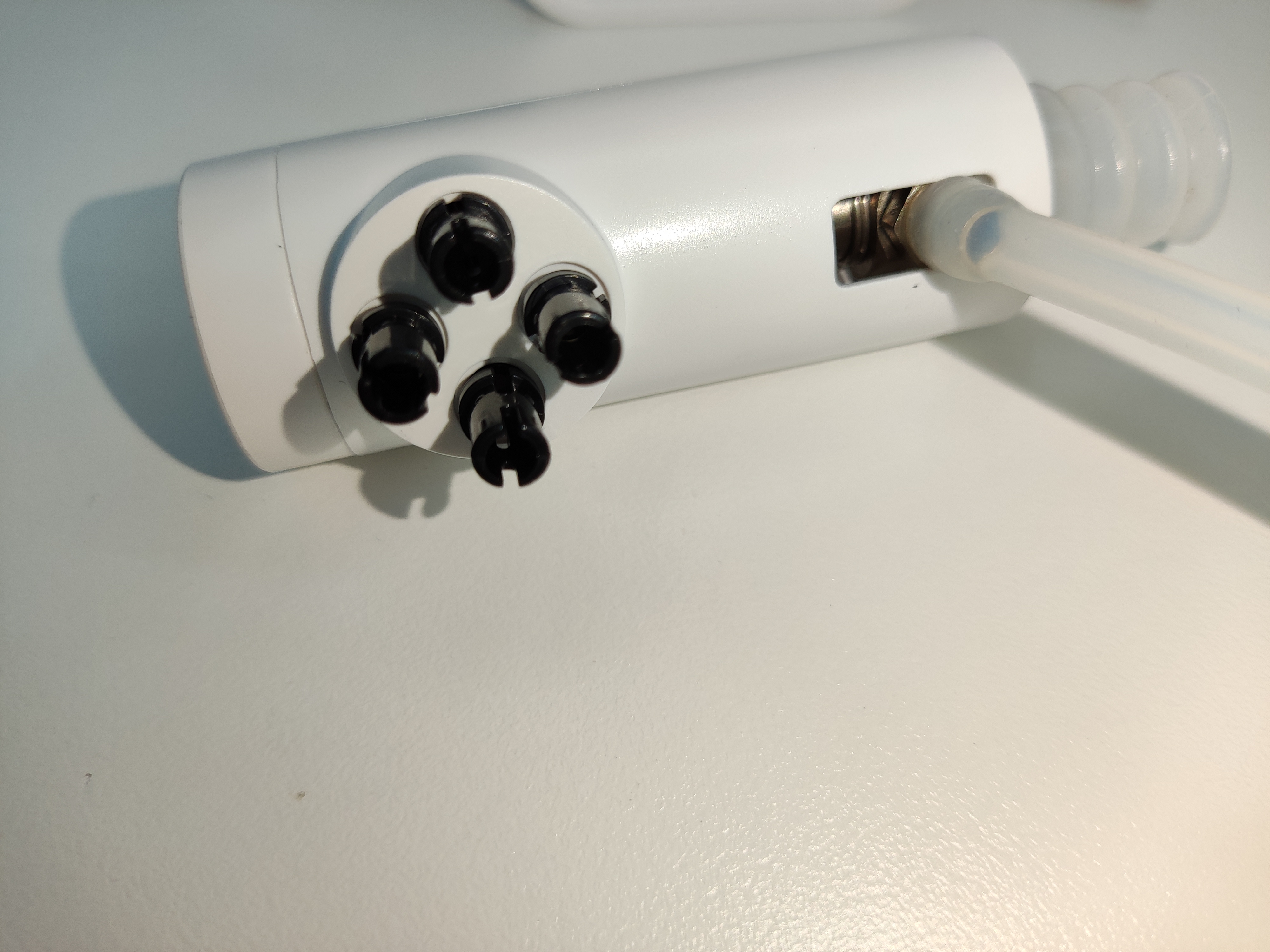

| Number of suction cups | 1 |

| Suction cup size | diameter 20mm |

| absorb weight | 150g |

| Power source equipment | Suction box |

| service life | one year |

| a fixed way | Lego Connectors |

| control interface | I/O control |

| Use environment requirements | Temperature and pressure |

| Applicable equipment | ER myCobot Series 280, ER myPalletizer Series 260, ER mechArm Series 270, ER myBuddy Series 280 |

Suction pump: used for adsorbing objects

Introduction

Suction pump, that is, vacuum adsorption pump, has a suction nozzle with one inlet and one outlet, and one exhaust nozzle. It has the advantages of simple structure, small size, convenient use, low noise, and good self-priming ability. By controlling the suction pump kit as the end effector of the robotic arm, it performs the function of absorbing objects.

Suction pump accessories: power cord x1, DuPont line x10, one-in-two-out connection line x1, Lego tech parts x several

working principle

When absorbing items: the air pump starts to pump air to absorb the items and then stops, and there will be no air leakage for a short time.

When putting down the item: the electronic valve is activated, the air release valve is opened, and the air enters the vacuum suction cup and separates from the sucked item.

·

Applicable object

Paper/Plastic

flat smooth object

card etc.

Installation diagram (take the M5 version as an example):

Wiring diagram

Installation and use

Check that the kit stuff is complete: LEGO connectors, Dupont wire, double-ended suction pumps

Double-ended suction pump installation:

Structural installation:

Insert the LEGO connection into the reserved socket on the suction pump:

Installation in two different orientations is possible depending on the requirements.

Method 1 Method 2

Method 2

Insert the suction pump with the inserted connections against the end socket of the robot arm:

Method 1

Method 2

Method 2

Electrical Connection:

Select a male-female DuPont cable and insert the female end into the socket marked with a pin on the suction pump square box:

Male-female Dupont wire:

Note the correspondence between the Dupont wire colours and the pins in the diagram:

Note the correspondence between the Dupont wire colours and the pins in the diagram:

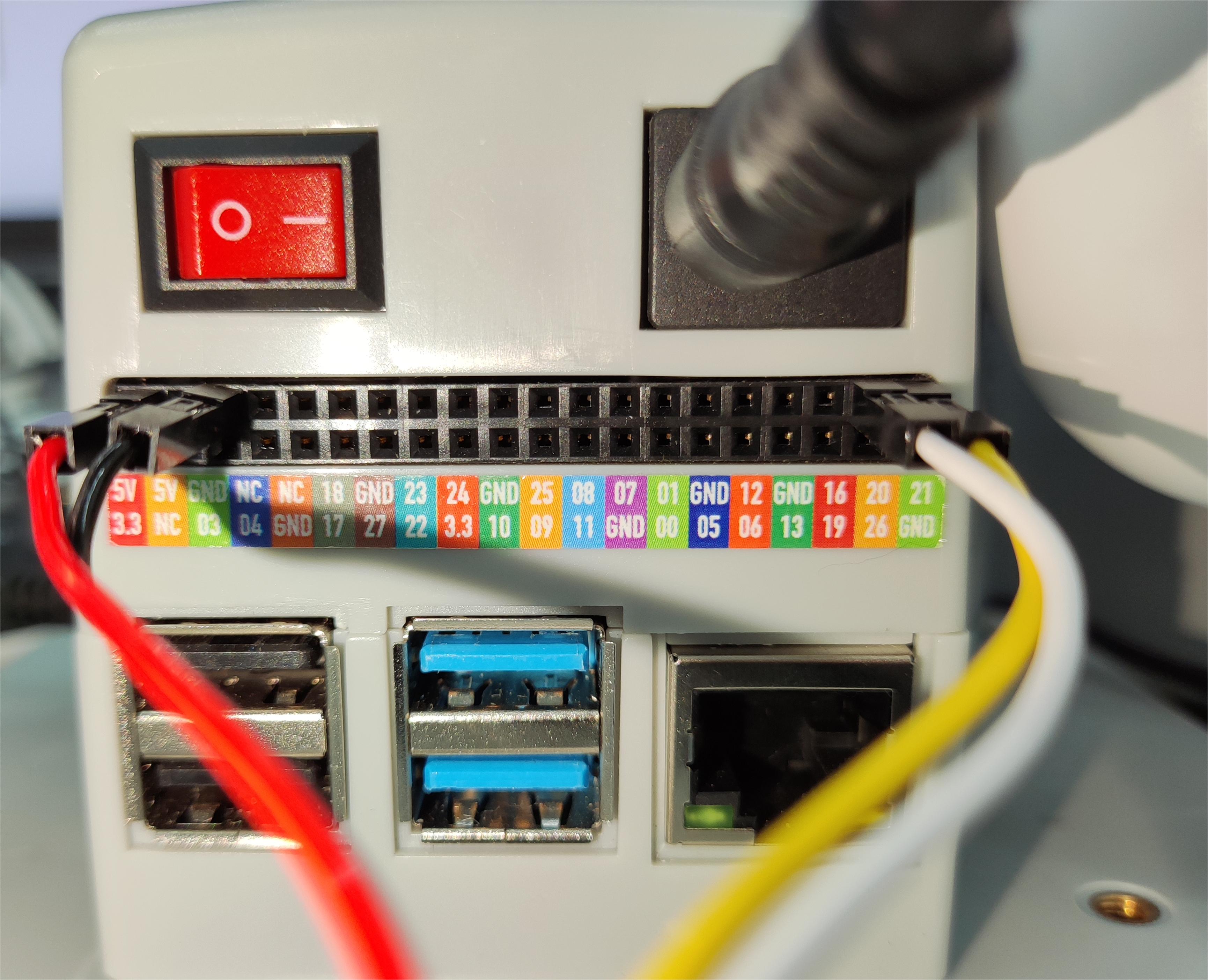

The male header is inserted into the robotic arm base pins according to the correspondence given:

Suction pump pins on the left, robotic arm pins on the right

GND -> GND

5V -> 5V

G2 -> 21

G5 -> 20

Software-driven testing:

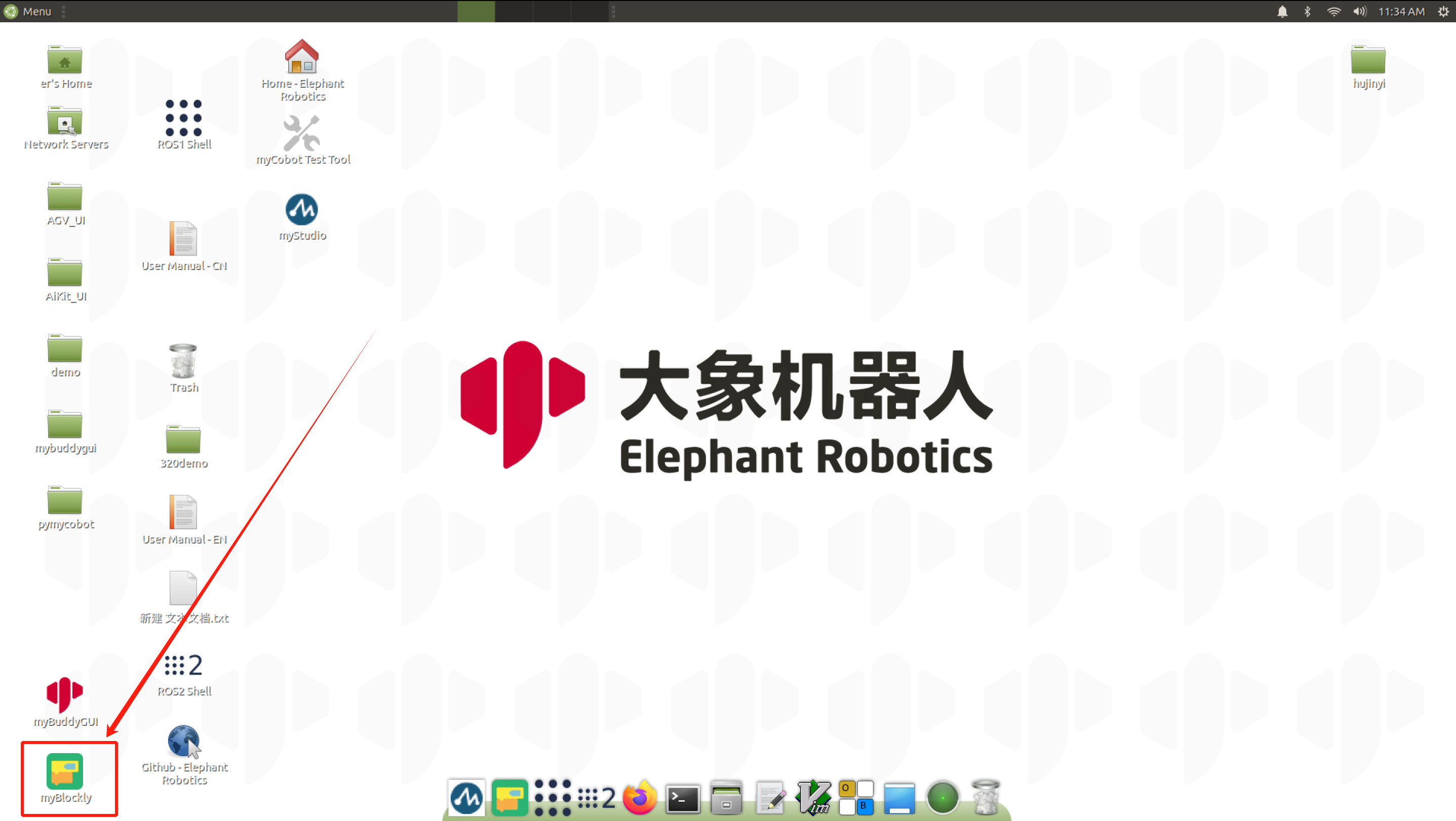

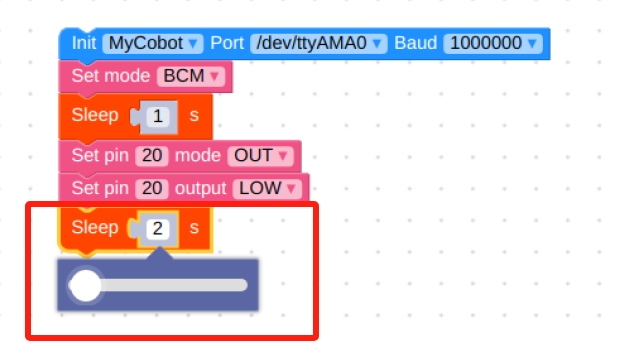

To test if the jaws are available after installation, use myBlockly. myblockly 下载

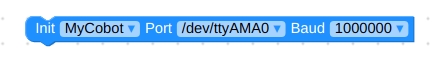

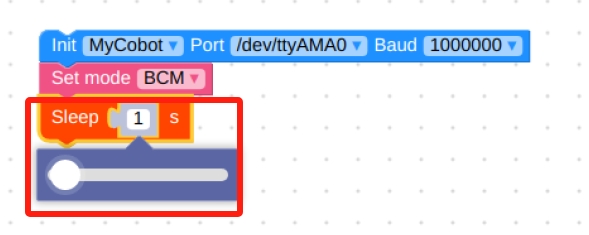

- After confirming that the structural and electrical connections are complete, start the arm and open the myblockly software when the graphical interface appears.

- Modify the baud rate to 1000000

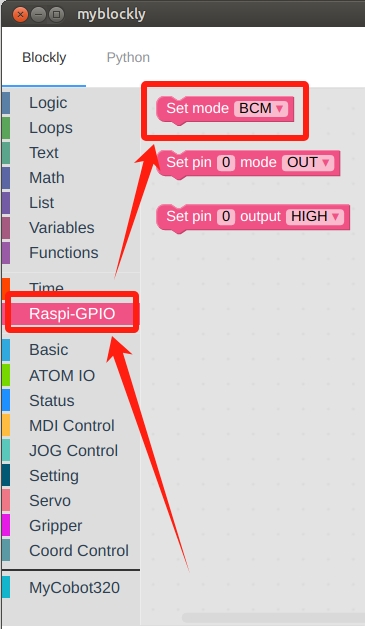

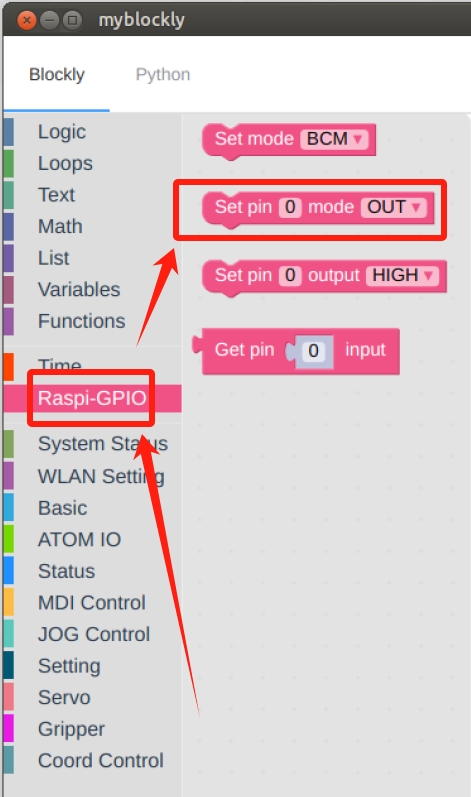

- Find

Raspi-GPIOin the list on the left and selectSetup Modemodule

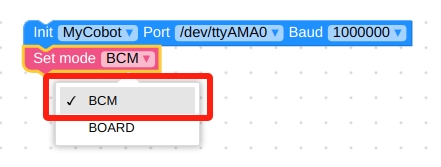

- Drag the module connection under

initialise mycobot moduleand select BCM mode

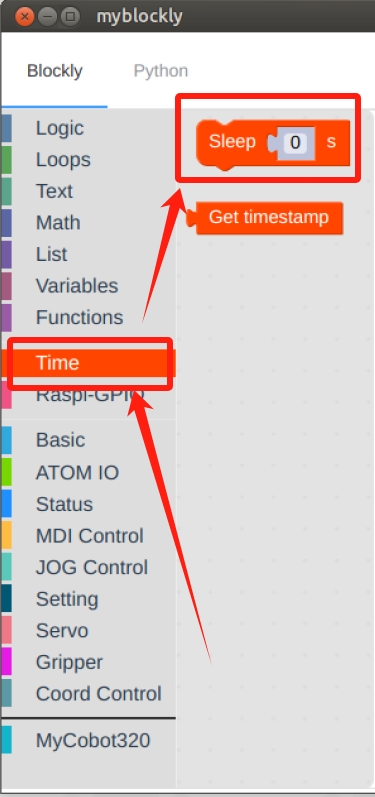

- In

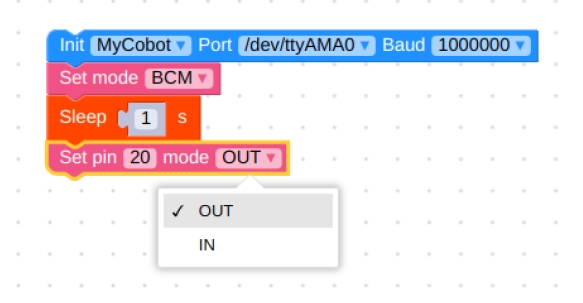

Time, selectSleepmodule

- Setting the time to

1 secondis intended to give buffer time

- Select the

Set Pin Modemodule

- Set pin

20toOUT, i.e. output mode

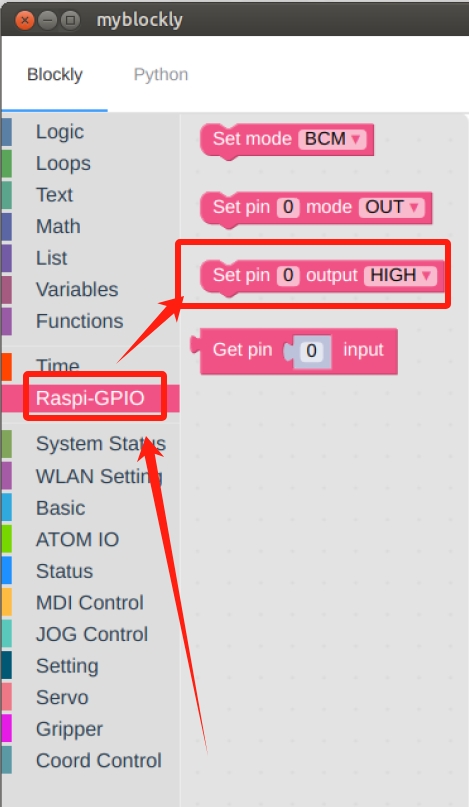

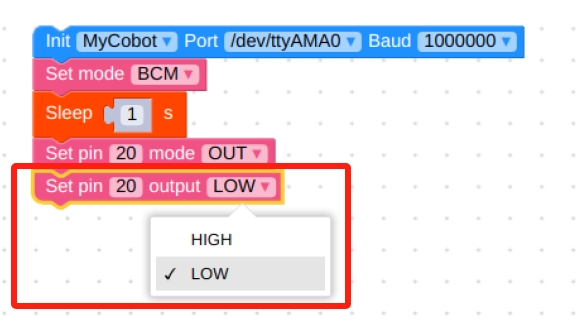

- Select the

Set Pin Outputmodule

- Set

20pin output toLOWlow, suction pump operates at low level

- Select the

Sleepmodule and set the time to2 secondsto allow time for the jaws to move.

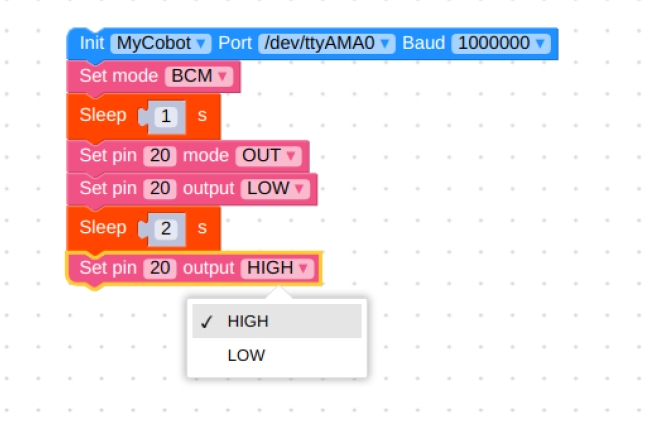

- Set the output of pin

20toHIGH, at which time the suction pump will stop working

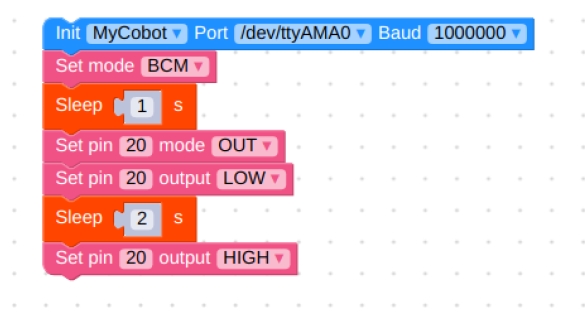

- The final result is as follows, click on the green Run button in the upper right corner to run it.

You can see that the suction pump turns on, runs for 2 seconds and then stops.

The second time you run it, you'll get a message sayingthis channel is already in use, continuing anyway, which is normal, and the python development section explains how to get around it.

- After confirming that the structural and electrical connections are complete, start the arm and open the myblockly software when the graphical interface appears.

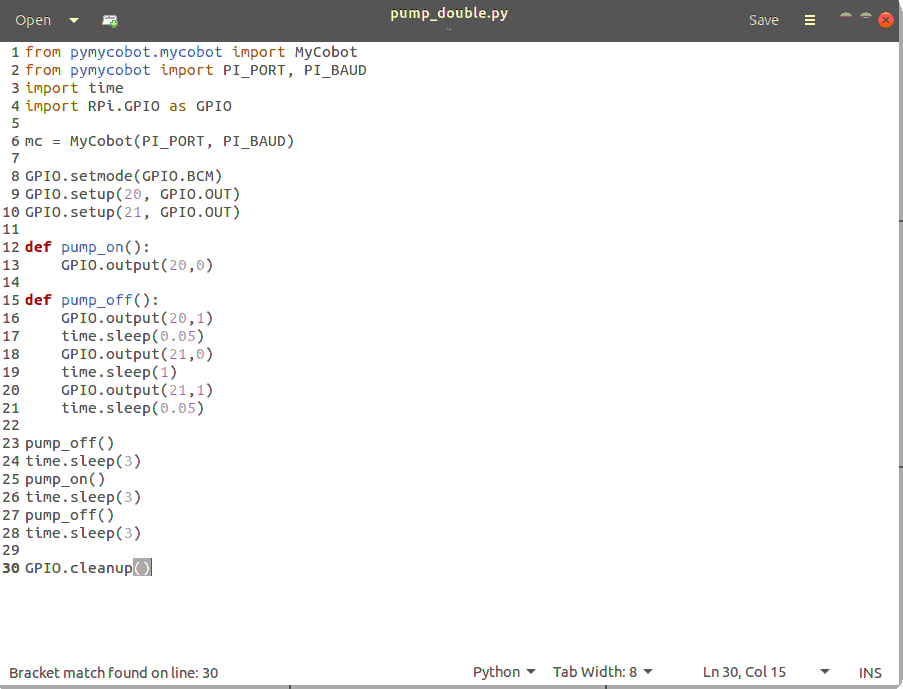

Programming Development:

Programming of suction pumps using python

python downloadCreate a new python file:

Ctrl + Alt + TOpen the command line and type:gedit pump_double.py

The file name can be changed as needed

Perform function programming:

The code is as follows:

- 280-M5 version:

from pymycobot import MyCobot280 import time # Initialise a MyCobot280 object mc = MyCobot280("COM3", 115200) # Switch on the suction pump def pump_on(): # Open the solenoid valve mc.set_basic_output(5, 0) time.sleep(0.05) # Stop suction pumps def pump_off(): # Close the solenoid valve mc.set_basic_output(5, 1) time.sleep(0.05) # The air relief valve starts to operate mc.set_basic_output(2, 0) time.sleep(1) mc.set_basic_output(2, 1) time.sleep(0.05) pump_off() time.sleep(3) pump_on() time.sleep(3) pump_off() time.sleep(3) GPIO.cleanup() # releases pin channel- 280-Pi Version:

from pymycobot import MyCobot280 from pymycobot import PI_PORT, PI_BAUD # When using the Raspberry Pi version of mycobot, these two variables can be referenced for MyCobot280 initialisation import time import RPi.GPIO as GPIO # Initialise a MyCobot280 object mc = MyCobot280(PI_PORT, PI_BAUD) # initialisation GPIO.setmode(GPIO.BCM) # Pins 20/21 control the solenoid valve and air release valve respectively GPIO.setup(20, GPIO.OUT) GPIO.setup(21, GPIO.OUT) # Switch on the suction pump def pump_on(): # Open the solenoid valve GPIO.output(20,0) # Stop suction pumps def pump_off(): # Close the solenoid valve GPIO.output(20,1) time.sleep(0.05) # Open the bleeder valve. GPIO.output(21,0) time.sleep(1) GPIO.output(21,1) time.sleep(0.05) pump_off() time.sleep(3) pump_on() time.sleep(3) pump_off() time.sleep(3) GPIO.cleanup() # releases pin channel

For more case references and running result videos, please view the use case