机械臂异常查看以及处理方法

当机械臂未成功执行运动指令时,可以在python终端中查询到对应的异常信息, 例如

1 读取机器人状态

1.1 状态反馈解析

正常情况下此接口反馈全0,读取机器人状态,左右臂不一致,具体如下:

m.get_robot_status() #读取机器人状态

左臂返回解析:

[0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0]表示:

机器人未在运动,无关节超限,无关节硬件报错、无关节软件报错

各个值完整解析如下:</br> [保留,是否正在运动,J1是否超限,J2是否超限,J3是否超限,J4是否超限,J5是否超限,J6是否超限,J7是否超限,J1是否电机硬件报错,J2是否电机硬件报错,J3是否电机硬件报错,J4是否电机硬件报错,J5是否电机硬件报错,J6是否电机硬件报错,J7是否电机硬件报错,J1是否软件报错,J2是否电机软件报错,J3是否软件报错,J4是否软件报错,J5是否软件报错,J6是否软件报错,J7是否软件报错]

案例如下:

[0,1,0,0,0,0,0,0,0,0,0,0,3,0,0,0,0,0,0,0,0,0,0]表示:

机器人在运动时报错,J4报控制错误

[0,0,0,1,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0]表示:

机器人J2超限

[0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,3,0,0]表示:

机器人J5线路异常--接收报错

右臂返回解析:

[0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0]表示:

机器人未在运动,无关节超限,无关节硬件报错、无关节软件报错

各个值完整解析如下:</br> [保留,是否正在运动,J1是否超限,J2是否超限,J3是否超限,J4是否超限,J5是否超限,J6是否超限,J7是否超限,J13是否超限,J1是否硬件报错,J2是否硬件报错,J3是否硬件报错,J4是否硬件报错,J5是否硬件报错,J6是否硬件报错,J7是否硬件报错,J13是否硬件报错,J11是否硬件报错,J12是否硬件报错,J1是否软件报错,J2是否电机软件报错,J3是否软件报错,J4是否软件报错,J5是否软件报错,J6是否软件报错,J7是否软件报错,J13是否软件报错]

案例如下:

[0,1,0,0,0,0,0,0,0,0,0,0,0,4,0,0,0,0,0,0,0,0,0,0,0,0,0,0]表示:

机器人在运动时报错,J4报控制错误

[0,0,0,1,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0]表示:

机器人J2超限

[0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,1,0,0,0]表示:

机器人J5线路异常--接收报错

[0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0,1,1,0,0,0,0,0,0,0,0]表示:

机器人双目、脖子无通信

1.2 异常解决

关节超限

关节超限时,可使用以下解决方法之一:

执行超限回零

m.over_limit_return_zero() #机器人会以较慢速度回到原点

执行关节放松,手动将关节移动到限位内

m.release_all_servo()

关节硬件报错

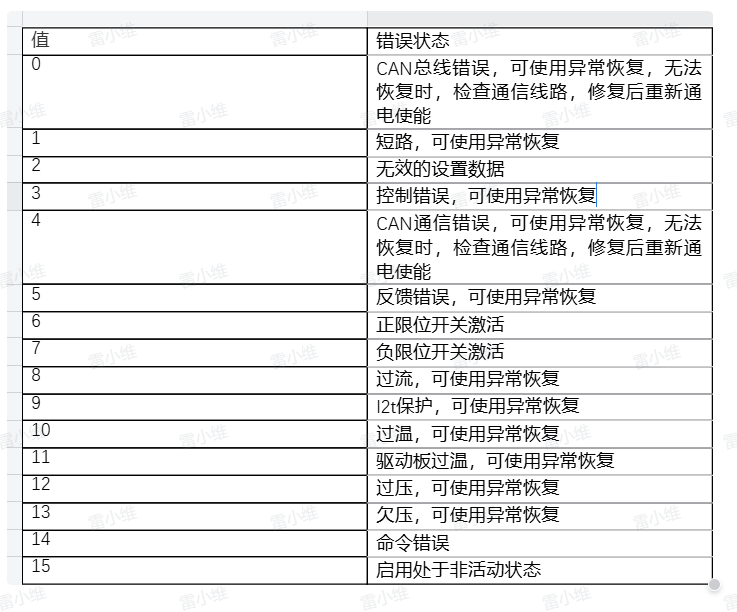

大部分硬件报错可以使用异常恢复,m.servo_restore(ID),若使用异常恢复或者机器人重启后,仍然频繁出现此问题,请联系我方工程师,具体各关节硬件详细报错见图1:

关节软件报错

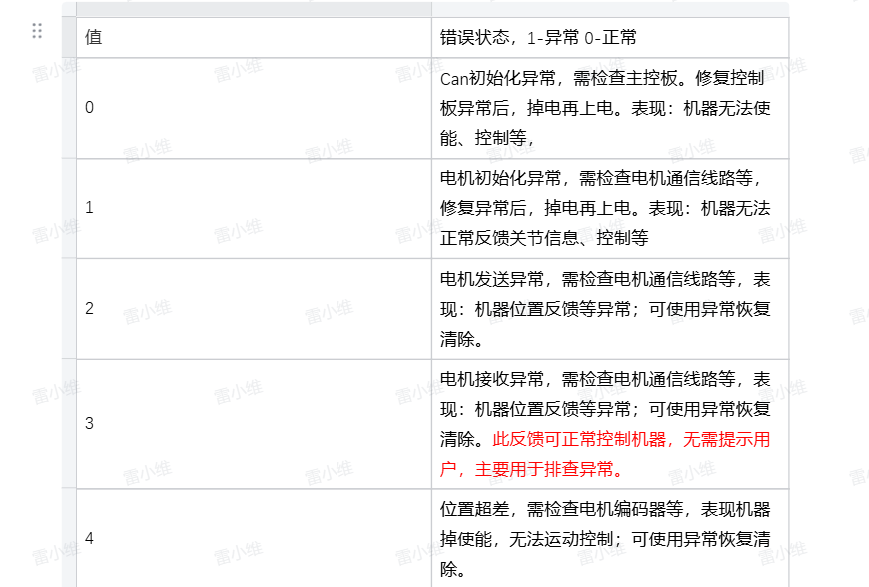

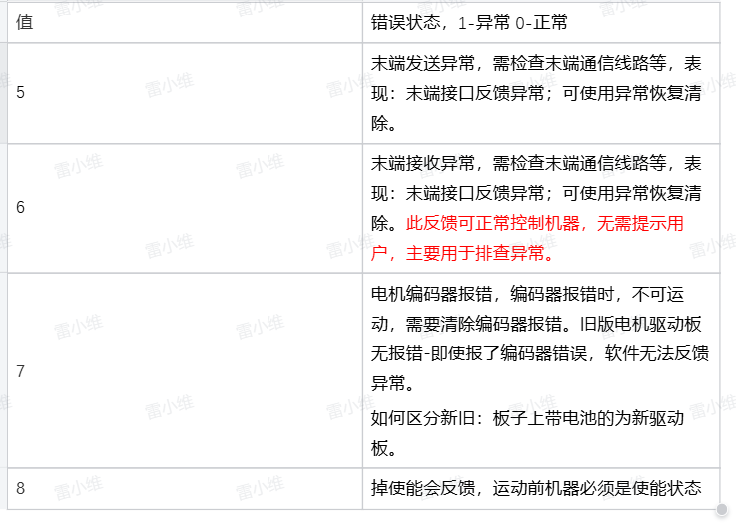

软件上的错误反馈主要为:线路异常、can模块异常、编码器异常、掉使能等,当出现掉使能,请使用m.focus_all_servo()上使能再运动,其它异常,请联系我方工程师,具体各关节软件详细报错见图2、图3:

机器人处于运动状态,机器人无法运动

机器人处于运动状态,发送运动点位不响应,请先将机器人运动停止,执行m.stop()、m.resume(),如仍然无法继续运动,请联系我方工程师。

2 查看执行运动指令的反馈

2.1.运动异常

控制机械臂运动到超限位置

form pymycobot import Mercury

m = Mercury('/dev/ttyAMA1')

m.set_joint_max_angles(1,45) #设置1关节限位为45°

m.send_angle(1,50,10) #控制1关节旋转至50°

此时机械臂会在限位处停止运动,并显示以下信息:

错误:关节1临近限位,当前角度为45.535, 角度范围为: -165.0 ~ 45.0

处理方法:根据提示的角度范围避开软件限位

笛卡尔运动

m.send_angles([0.0, 0.0, 0.0, -90.0, 0.0, 89.999, 0.0], 10) #控制机械臂到起始姿态

m.send_coord(1,-200,10) #控制机械臂运动到x=-200的坐标位置

此时可以观测到机械臂执行到中途停止,同时显示以下信息:

错误:关节2临近限位,当前角度为-49.967, 角度范围为: -50.0 ~ 120.0

处理方法:根据提示的角度范围避开软件限位

m.send_coord(3,500,10) #控制机械臂运动到z=500的坐标位置

此时可以观测到机械臂执行到中途停止,同时显示以下信息:

错误:直线运动无相邻解。请检查机器人手臂跨度是否接近极限。当前臂展为370, 最大的臂展为440

处理方法:控制机械臂收缩

m.send_angles([0.0, 0.0, 0.0, -90.0, 0.0, 0, 0.0], 10) #更换初始姿态

m.send_coord(1,200,10) #控制机械臂运动到x=200的坐标位置

此时可以观测到机械臂未响应指令,同时显示以下信息:

错误:奇异位置无解。请使用send_angles()方法离开该位置。在关节 6 处检测到奇点:0.0 度

处理方法:根据提示离开奇异位置

m.send_angle(6,90,10) #使用关节运动离开奇异位置

m.send_coord(1, 474, 10) #发送一组超出机械臂里程的坐标

此时可以观测到机械臂未响应指令,同时显示以下信息:

错误: 发送的坐标数据超出限位

处理方法:发送限位内坐标值

2.电机异常

固件版本 V1.0电机异常时,机械臂对运动指令无响应,此时终端中会显示对应的错误字,例如:

0x31(49):掉使能;

0x32(50):电机报错

0x33(51):电机编码器报错

出现掉使能错误,请上使能,执行以下程序:

m.focus_all_servos()

出现电机编码器报错,请查看当前跳变角度,执行程序见下方,然后整机断电,若仍然显示编码器异常,请联系我方工程师。

m.get_angles() #查看当前角度

出现电机报错后,执行下列程序

for i in range(1,8):

m.servo_restore(i) #清除电机报错

#重新上下电

m.power_off()

m.power_on()

若运动时仍然显示电机异常,请联系我方工程师。

3 使用注意

左臂执行power_off()后需要先执行power_on(),再右臂执行power_off()、power_on()启动机器人。