Pneumatic Gripper

Applicable models: myCobot 320, myCobot Pro 600, myCobot Pro 630

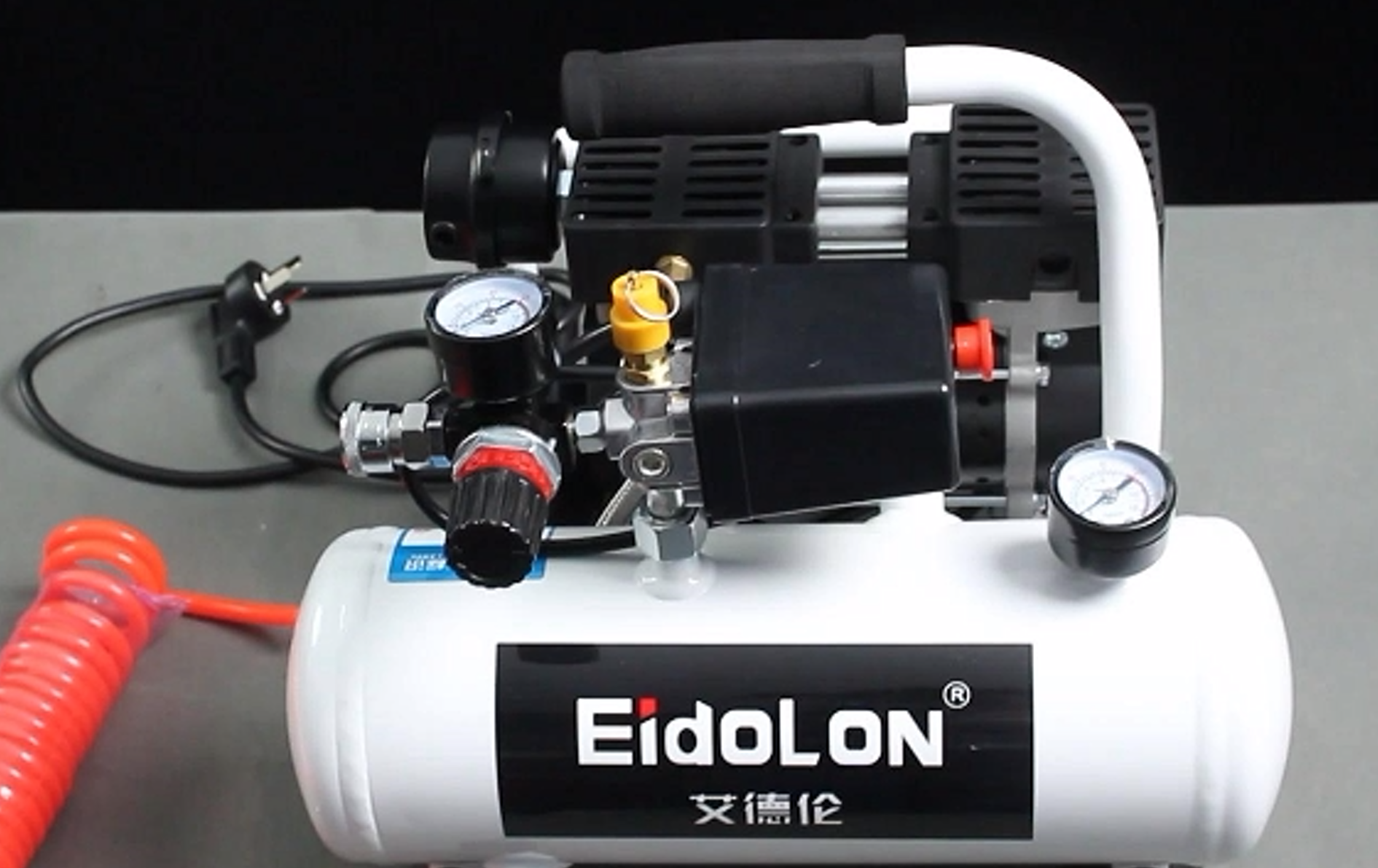

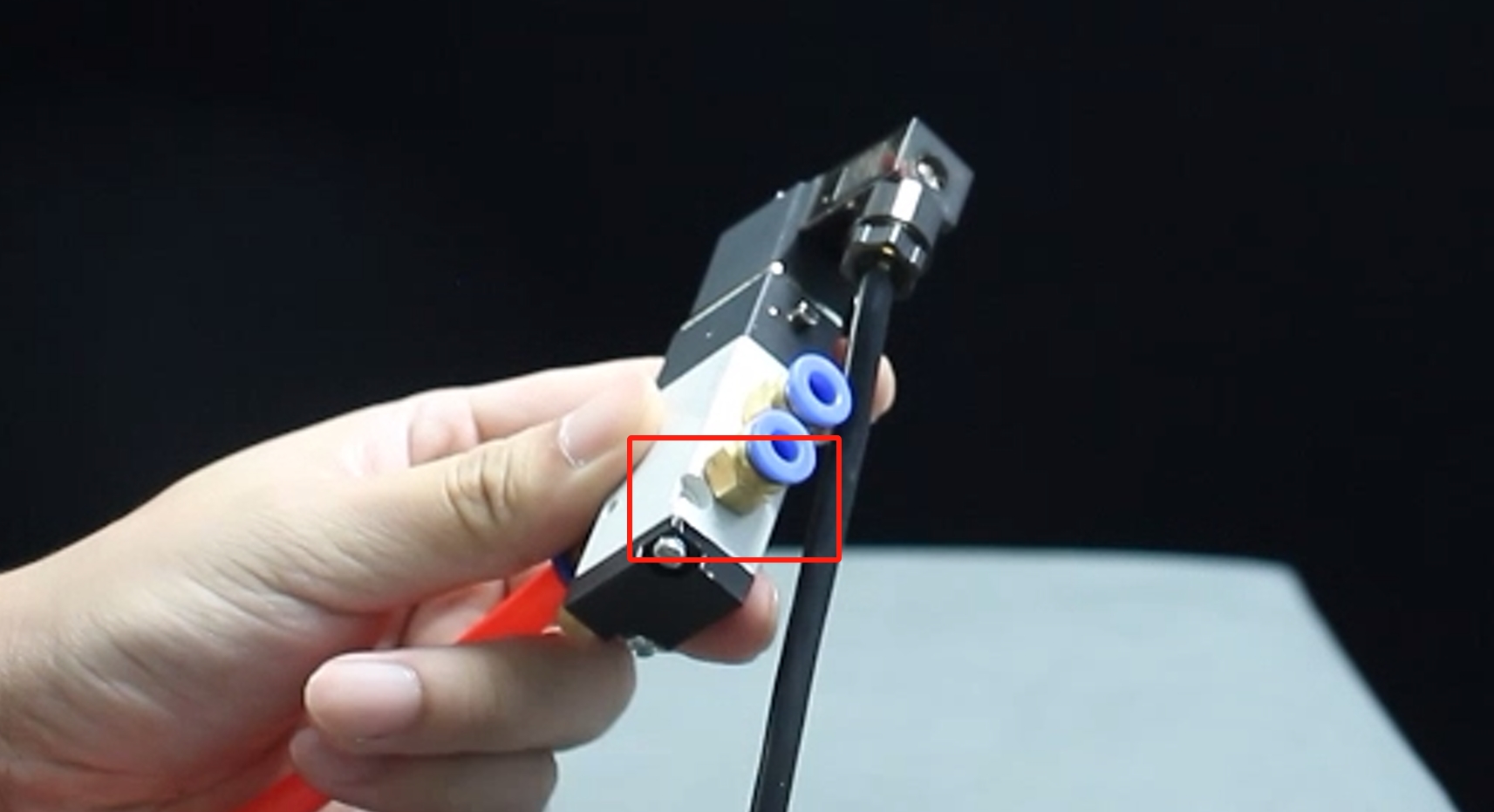

Product image

Specifications:

| Name | mycobot320 Pneumatic Gripper |

|---|---|

| Model | myCobotPro_Gripper_Air_10 |

| Process | Metal + 7500 Nylon |

| Clamping range Clamp size | 0-8mm |

| Maximum clamping force Clamp force | Outer diameter 34N Inner diameter 45N |

| Drive mode drive | Pneumatic |

| Transmission mode | Piston cylinder |

| Size size | 67.3×38×23.6mm |

| Weight | 180g |

| Fixing method Fixed | Screw fixing |

| Environment requirements | Normal temperature and pressure |

| Control interface control | IO control |

| Applicable equipment | myCobot 320, myCobot Pro 600, myCobot Pro 630 |

Pneumatic gripper: Used for gripping objects

Introduction

Pneumatic gripper, also known as pneumatic finger or pneumatic gripper finger, is an actuator that uses compressed air as power to grip or grasp workpieces. It is small in size, light in weight, compact in appearance, can realize single and double-way grasping, can be automatically aligned, has high repeatability, and the magnetic switch can realize automatic control.

The pneumatic gripper set includes a gripper flange, an air pump, a φ8 air pipe, a φ6 air pipe, a φ8-6 quick connector, a solenoid valve, and a cable. Its main function is to replace human grasping work, which can effectively improve production efficiency and work safety. An external suction pump is required.

Working Principle

Single piston: The axis drives the crank, and the air gripper is driven by the piston to open and close. There is a corresponding crank groove on each of the two claws. In order to reduce friction resistance, the claw and the body are connected to the steel ball slide structure.

Double piston: It is operated by two pistons. Each piston is connected to the pneumatic finger by a roller and a double crank to form a special drive unit. The pneumatic finger always moves axially and concentrically, and each finger cannot move alone. If the finger of the parallel gripper cylinder moves in the opposite direction, the previously compressed piston is in the exhaust state, and the other piston is in the compressed state.

Applicable objects

- Volume less than the gripping stroke

- Weight less than the maximum gripping weight

- Customized fingertips can expand more items

Installation and use

Need to be used with air compressor:

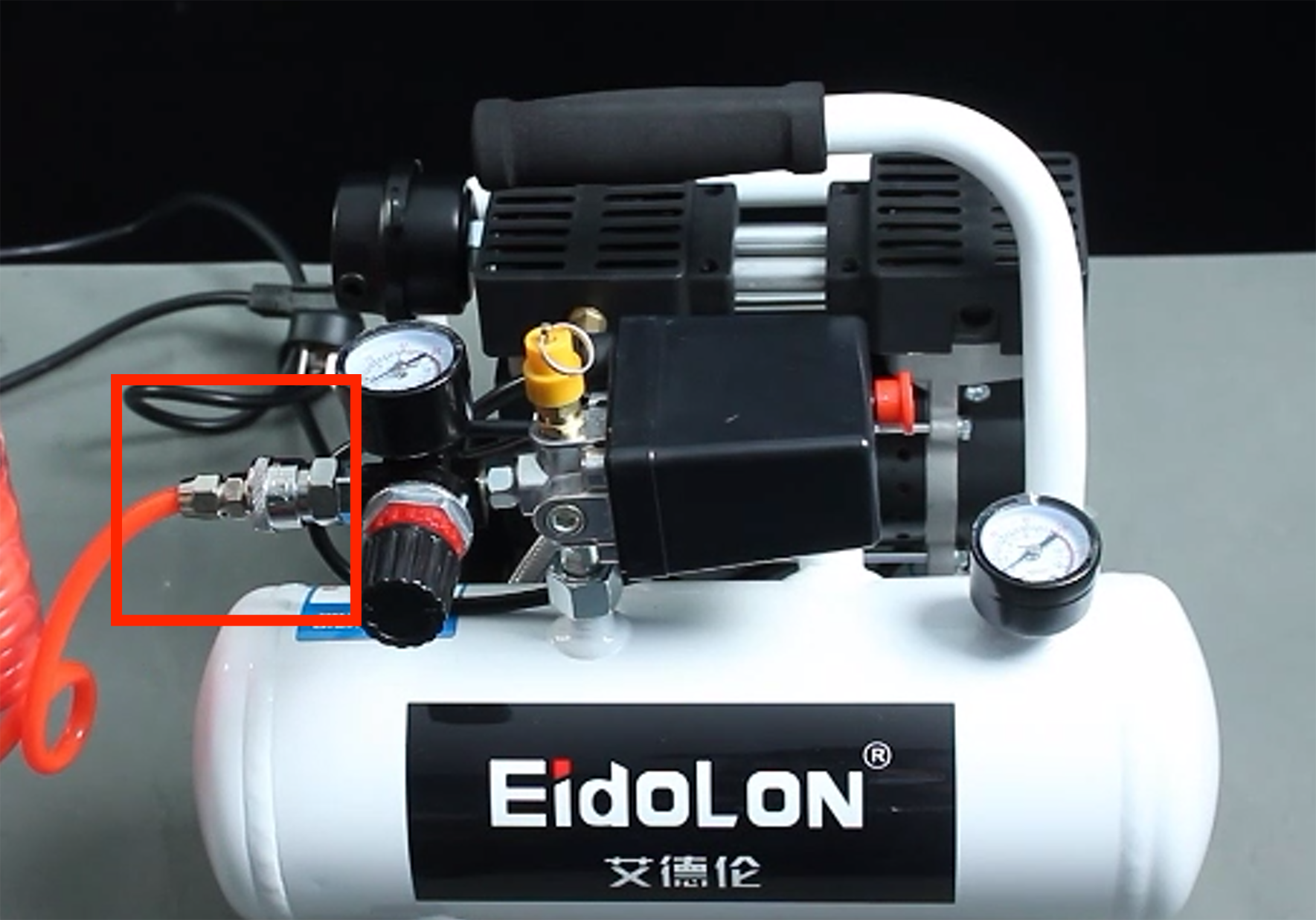

Plug the black plug into the power strip;

Plug the matching red hose into the interface on the machine:

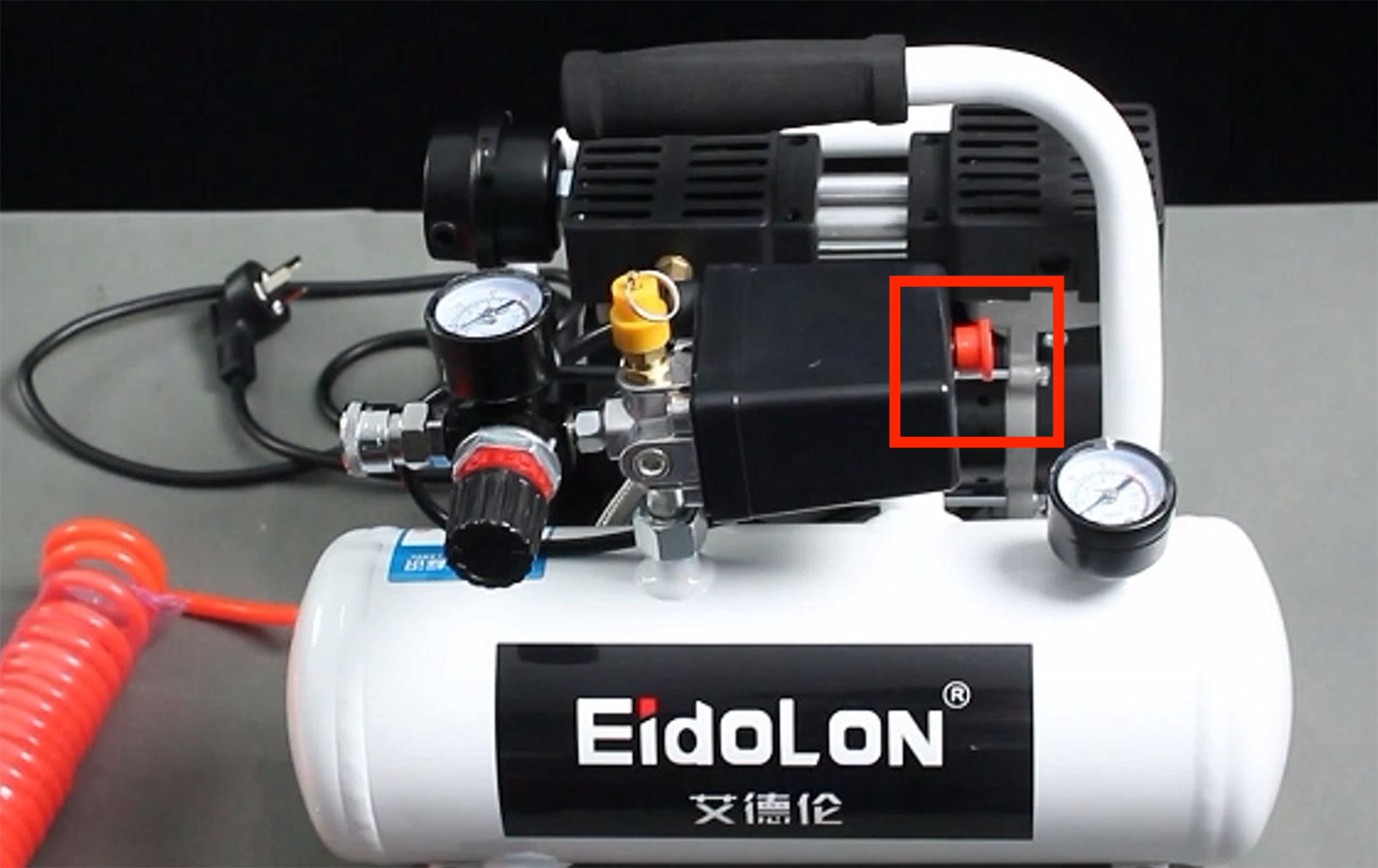

- The red button is a switch. Pull it out to turn it on, and press it back to turn it off:

Gripper installation:

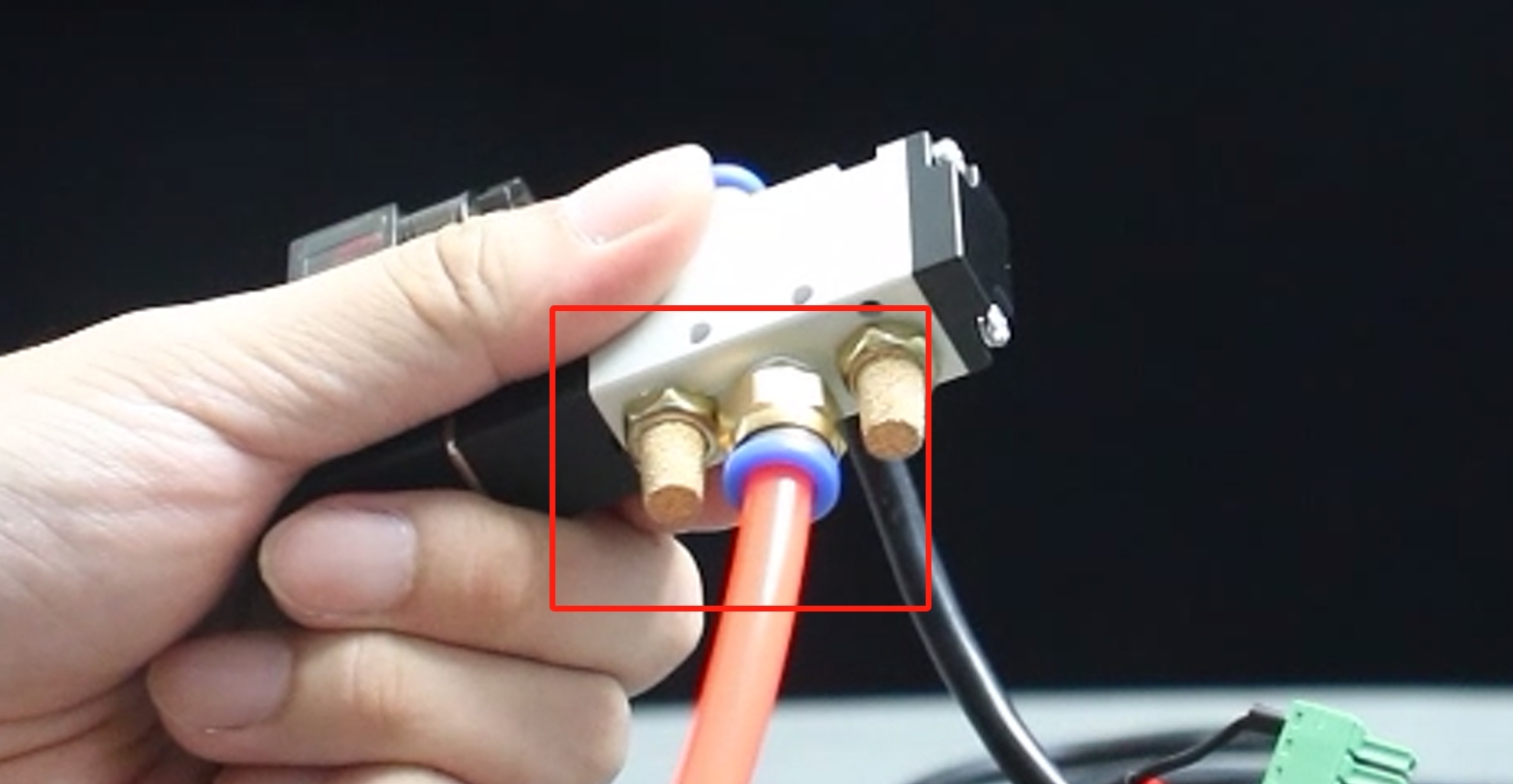

Connect the other end of the red hose of the air compressor to the interface of the solenoid valve:

- Unscrew another interface on the other end of the solenoid valve for starting the gripper to control the opening and closing:

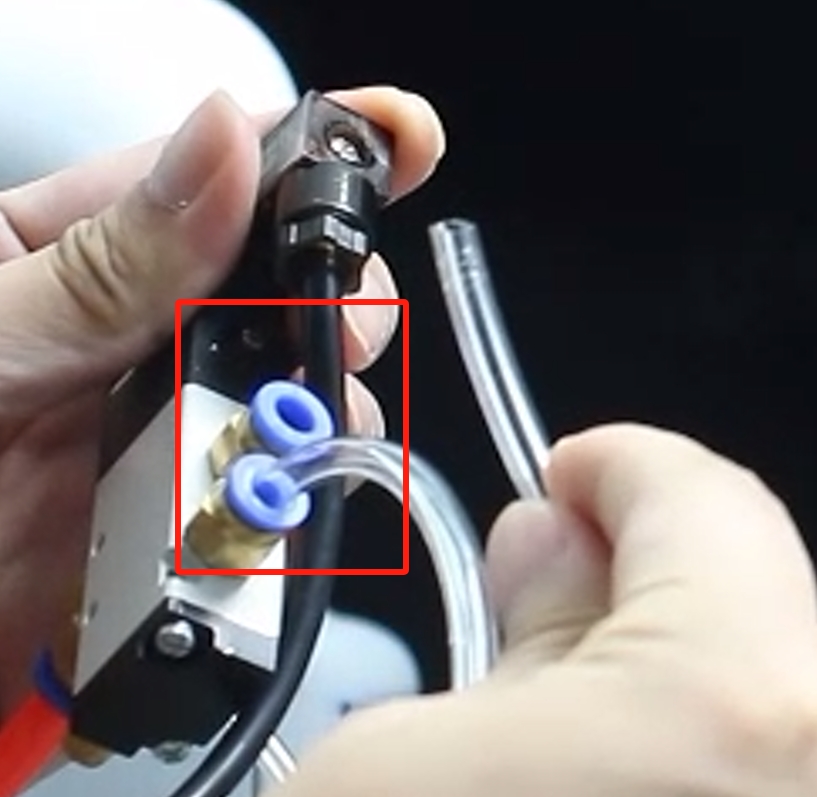

- Use two matching transparent hoses and connect one end to the two interfaces of the solenoid valve:

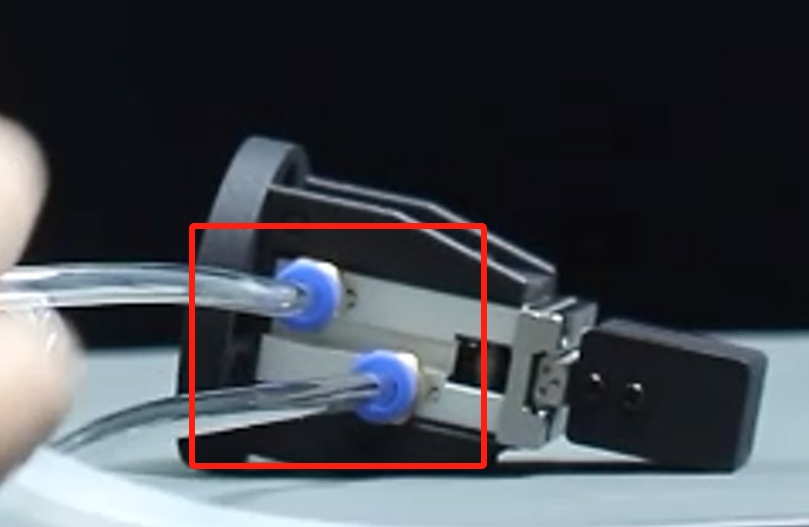

- The other end of the transparent hose is connected to the two interfaces of the gripper:

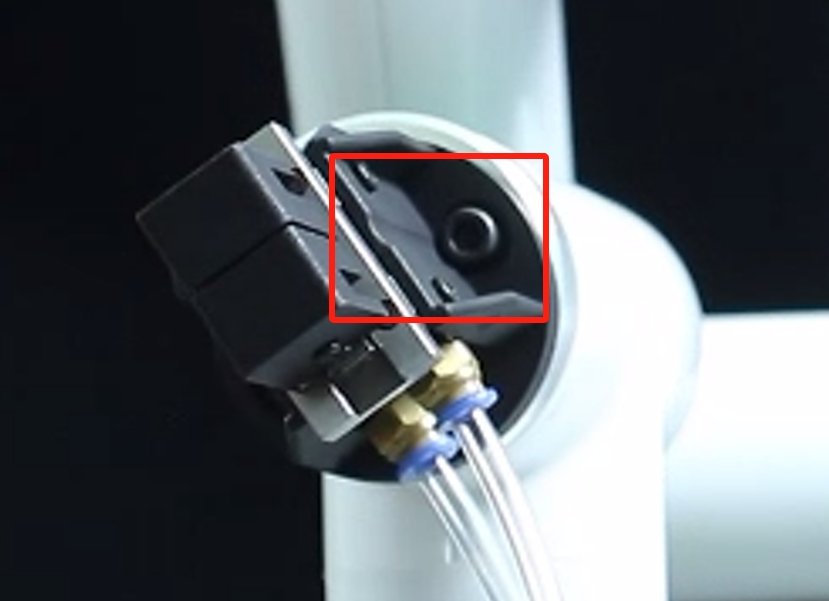

Fix the gripper to the end of the robot arm with the matching screws:

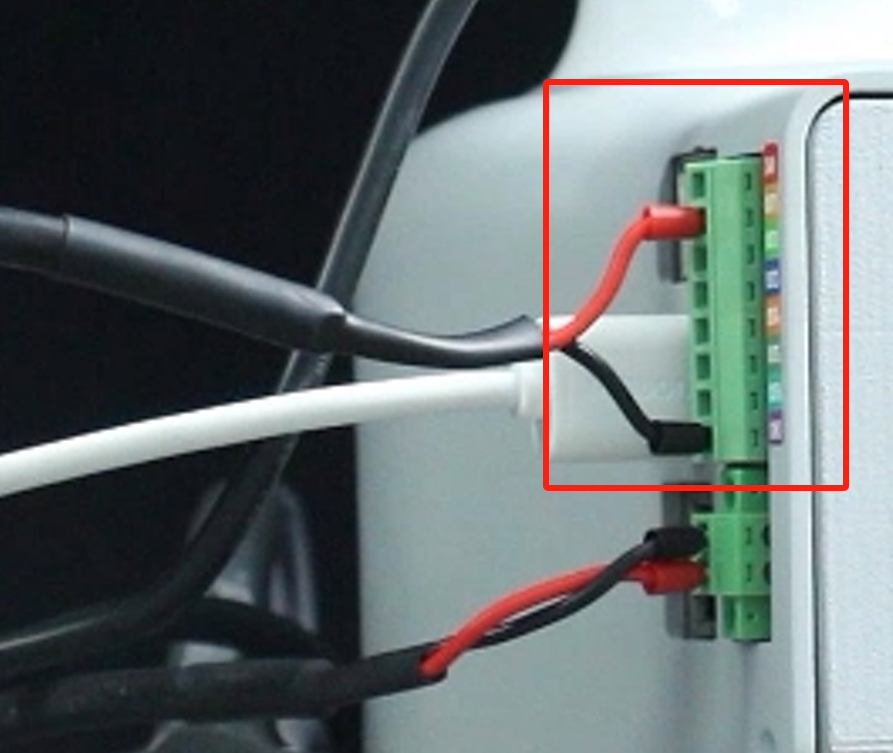

Electrical connection:

Connect the black cable to the GND of the robot arm base and the red cable to any one of OUT1~OUT6. Change the pin number of the subsequent program according to the selected interface. Here, use OUT1:

3 Through python Control

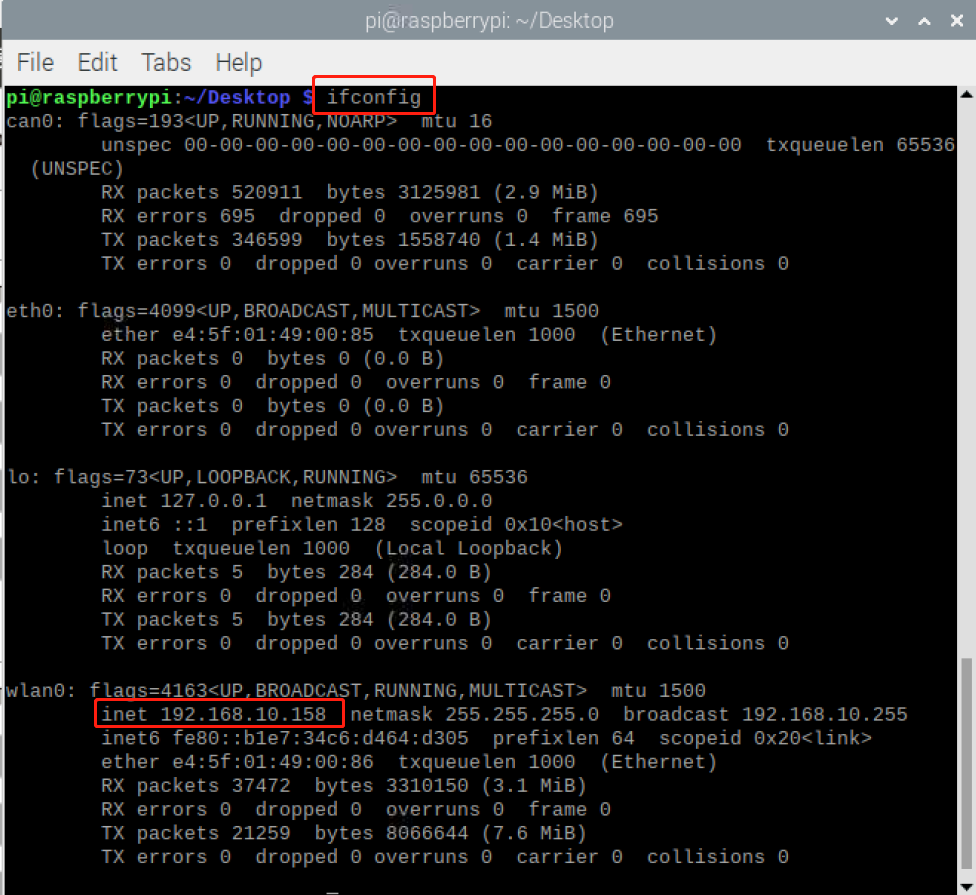

Confirm the IP address of the robot: Enter ifconfig in the terminal to obtain

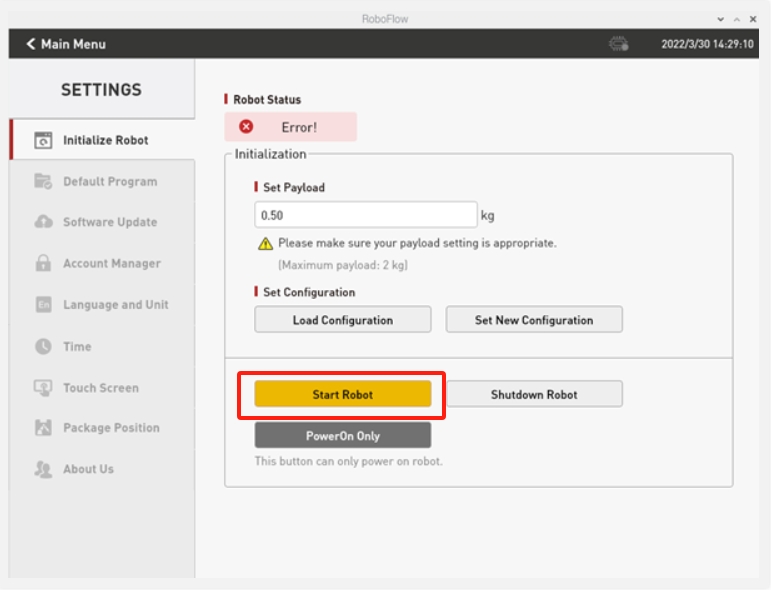

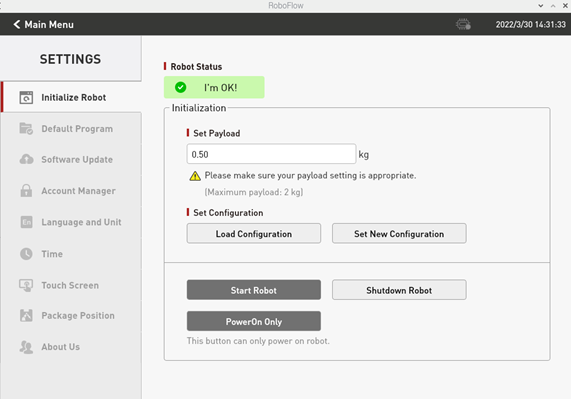

The robot system needs to be started before use

from pymycobot import ElephantRobot

import time

# Change the IP address to the real IP address of the P600 Raspberry Pi

elephant_client = ElephantRobot("192.168.1.137", 5001)

# Necessary instructions to start the robot

elephant_client.start_client()

time.sleep(1)

elephant_client.set_digital_out(0,1)

time.sleep(2)

elephant_client.set_digital_out(0,0)

time.sleep(2)