1 List of product standards

1.1 Product List Pictures

Information is being updated...

1.2 Product Standards List Comparison Table

| Serial Number | Product |

|---|---|

| 1 | myArm Master 750 robotic Arm |

| 2 | Product kit with USB-Type C, jumper cables, M6*35, cup hex head, fully threaded stainless steel screws |

| 3 | DC24V DC power supply |

| 4 | Fixed base plate |

| 5 | G-type nipple |

| 6 | Certificate of Conformity |

| 7 | emergency stop button |

Note: Once the box is in place, please make sure the robot packaging is intact. In case of damage, please contact the logistics company and the supplier in your area. After opening the box, please check the actual contents of the box against the list of items.

2 Product Unboxing Guide

2.1 Product Unboxing Graphic Guide

Why you need to follow the steps to disassemble the product

In this section, we strongly recommend following the specified steps for disassembling the product. This not only helps to ensure that the product is not damaged during transport, but also minimises the risk of accidental failure. Please read the following illustrated guide carefully to ensure the safety of your product during unpacking.

- 1 Check the packing box for damage. In case of damage, please contact the logistics company and the supplier in your area.

- 2 Open the box and take out the product brochure, sponge packaging cover, myCobot robot arm, matching power supply, emergency stop switch, flat base and accessory bag.

- 3 Make sure each step is completed before moving on to the next to prevent unnecessary damage or omissions.

Note: After removing the product, please check the appearance of each item carefully. Please check the actual items in the box against the list of items.

2.2 Product unboxing video guide

Information is being updated...

3 Structural installation and fixing

myArm weighs 3.2kg. Since the centre of gravity changes as the robot moves during use, it is required that the robot be fixed on a sturdy base from the outset. Either a fixed base or a mobile base is possible.

3.1 graphic guide

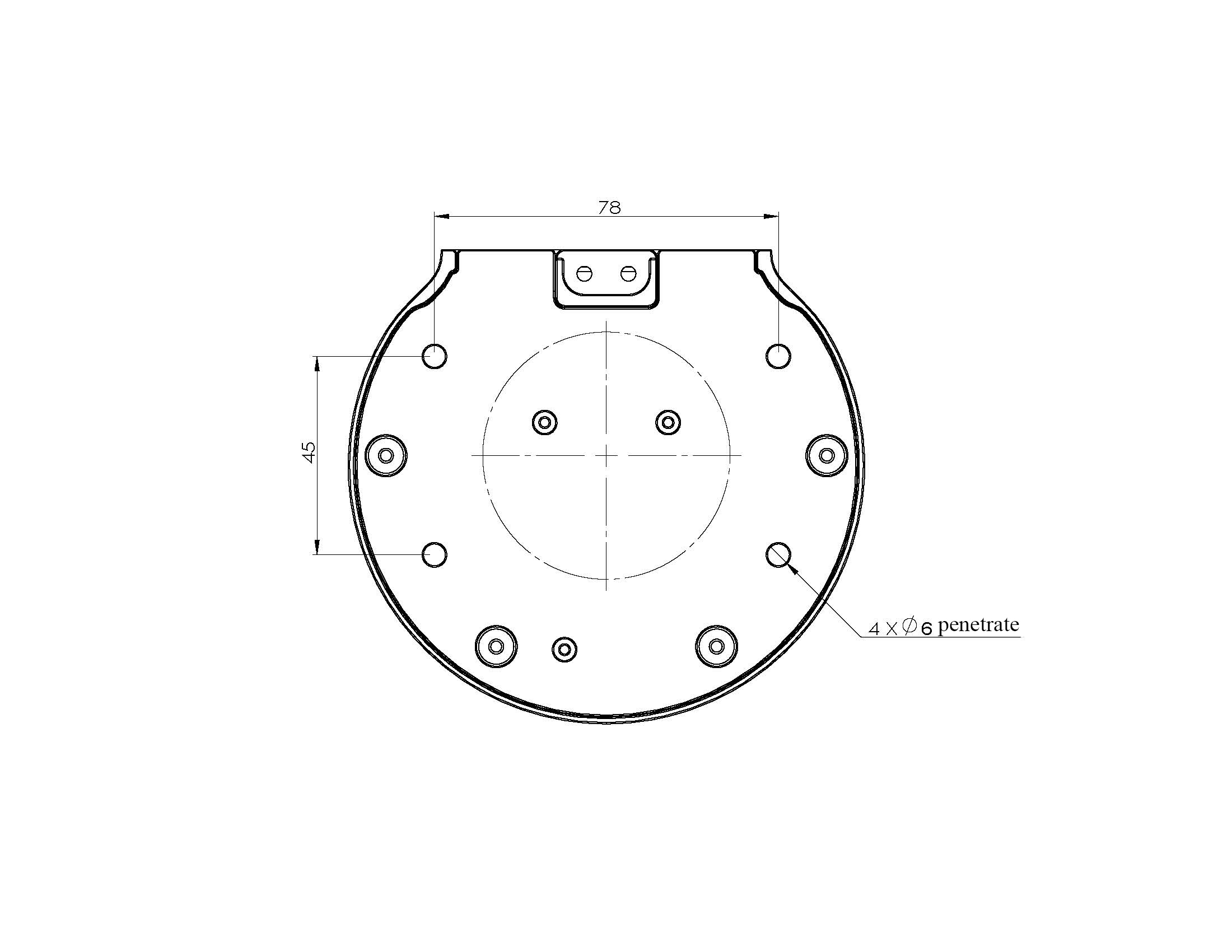

Basic Interface Dimensions

- The base mounting holes are the interface between the robot and other bases or planes. The holes are shown below. There are 4 countersunk holes with a diameter of 4.5 mm that can be secured with M6 bolts.

- The end mounts have flanges that are compatible with LEGO component holes and threaded holes. Ensure the appropriate threaded holes are present in the fixing base before installation.

Before installing, please make sure:

- Environmental conditions meet the requirements listed in section 2.2.4.3.1 above.

- The mounting position is not smaller than the working range of the robot and has sufficient space for installation, use, maintenance and repair.

- Place the base in a suitable position.

- Prepare tools related to installation, such as screws and spanners.

- After confirming the above steps, move the robot to the base mounting table, adjust the robot position, and align the fixing holes in the robot base with the holes in the base mounting table. After aligning the holes, align the screws with the holes and tighten them.

CAUTION: When adjusting the robot's position on the base mounting table, do not push or pull the robot directly on the base mounting table as this may cause scratches. When manually moving the robot, do not apply external force to the vulnerable parts of the body to avoid unnecessary damage to the robot.

- Once the robot is installed, it is ready for cable connection and use.

3.2 Video guide

For more installation details, scan the code to watch the video:

Information is being updated...

4 External cable connection

4.1 graphic guide

Before operation, make sure you have read Chapter 3 Safety Instructions to ensure safe operation. Meanwhile, connect the power adapter to the robot arm and fix the robot arm base on the table.

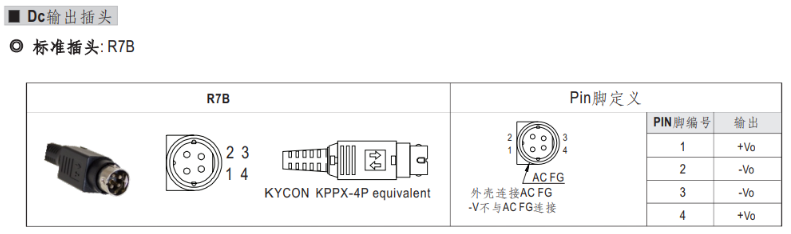

The myArm must be powered by an external power supply to provide adequate power:

Rated Voltage: 24V

Rated current: 9.4A

Plug Type: R7B

Please note that it is not possible to use only the plug-in TypeC power supply. Please use an officially approved power supply to avoid damaging the arm.

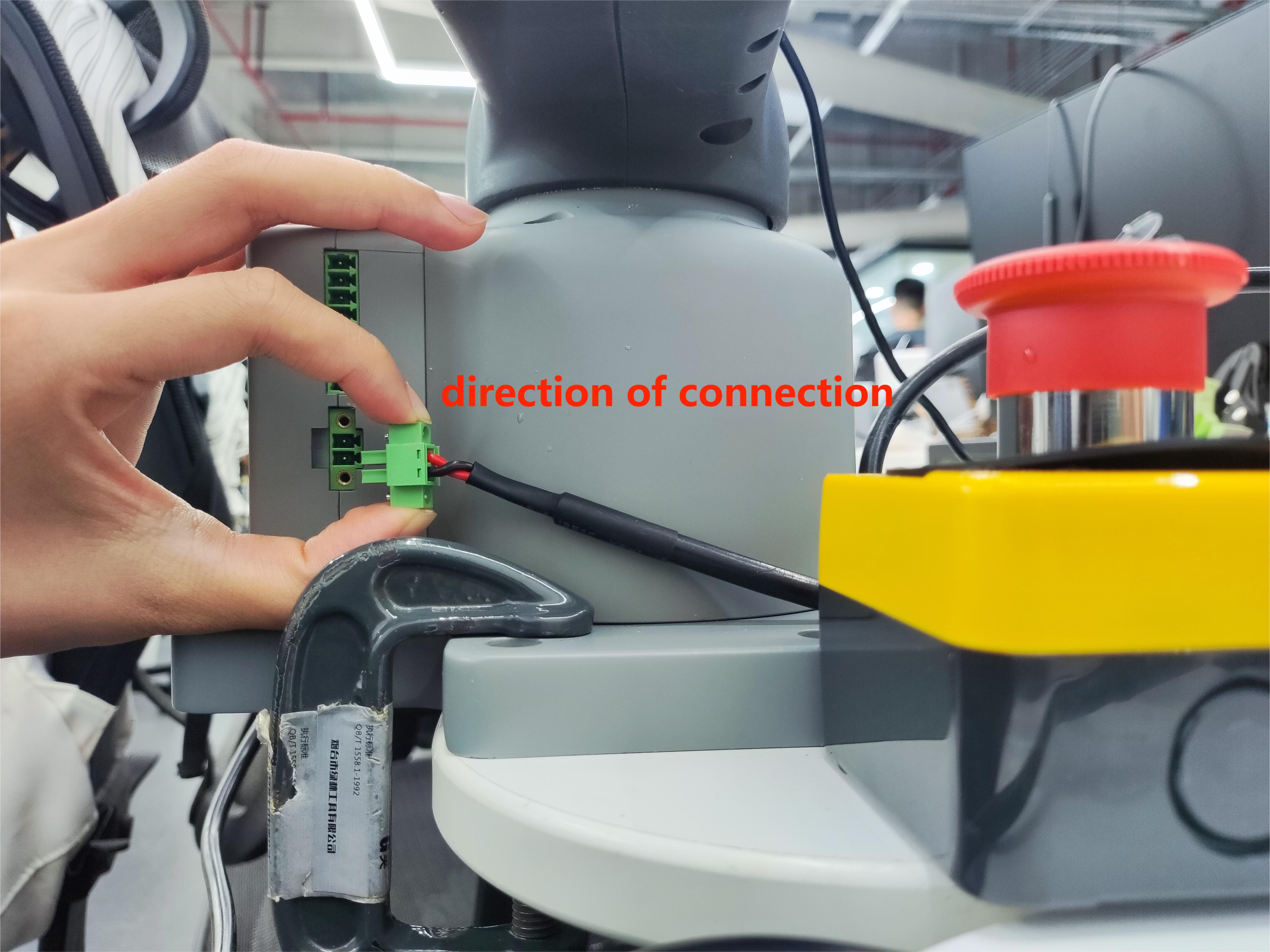

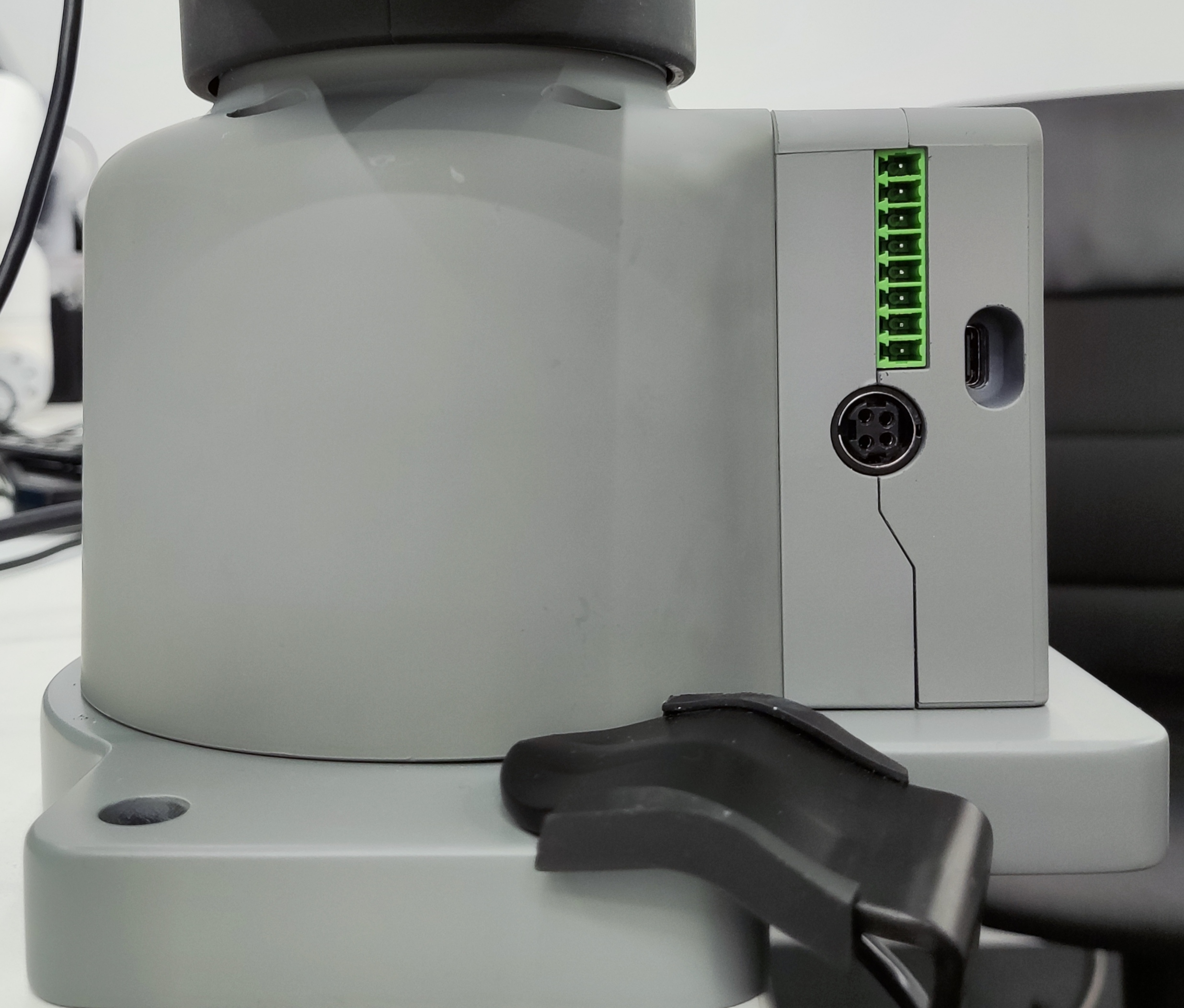

The use case diagram is shown below: (Please align the use case diagram carefully for connection)

Step 1:

Step 2:

Step 3:

Step 4:

Step 5:

Step 6:

5 Boot status display

5.1 Graphic guidance

5.1.1 Switching on the power supply

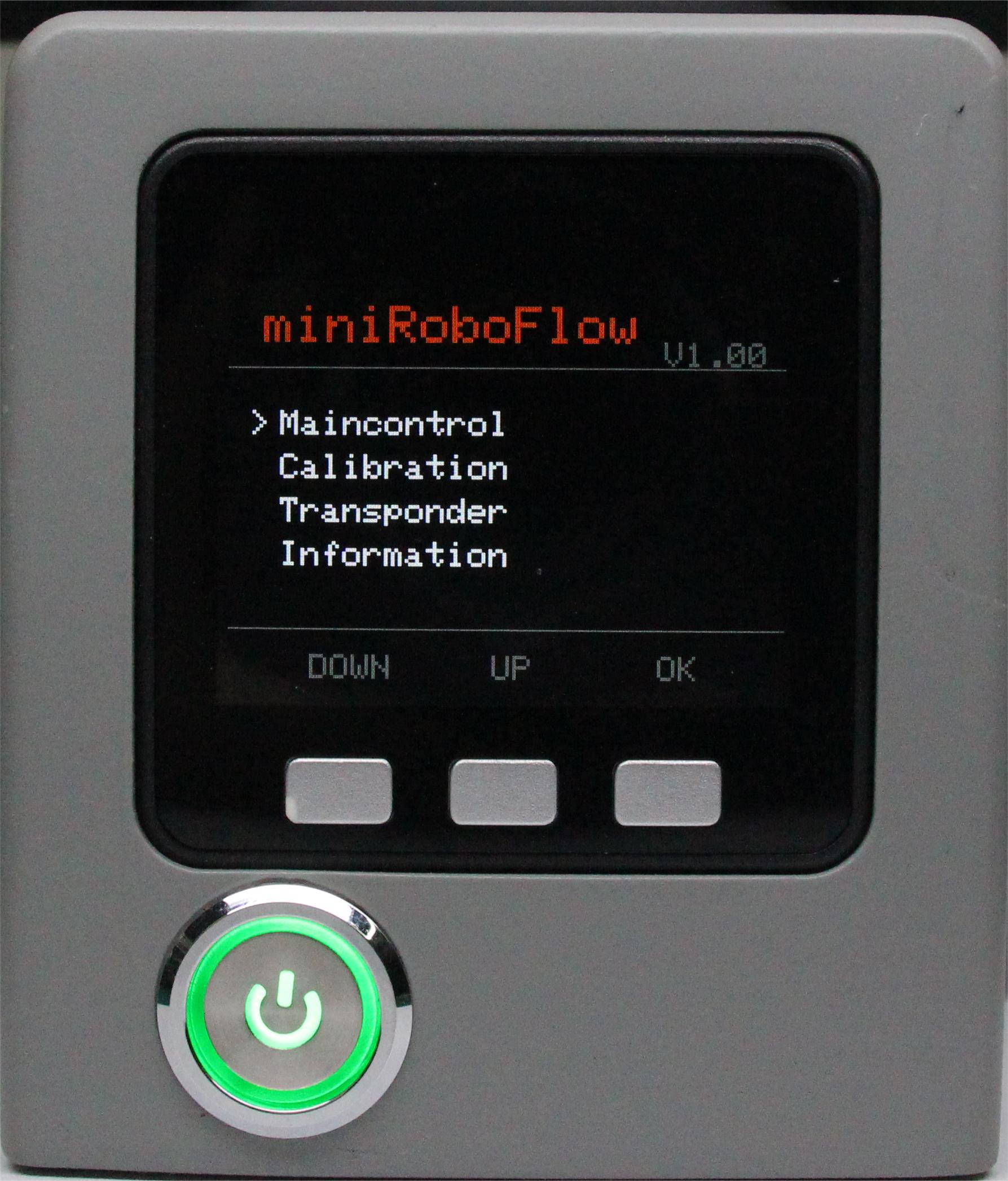

Ensure that the power adapter, emergency stop switch and HDMI monitor are connected and press the power switch Start button (round).

5.1.2 Machine Startup

During startup, the screen appears as a delayed wait screen.

5.1.3 Status Display

The display shows information about the system desktop.

If you have read all of this chapter, please continue to read the next chapter.

← Previous chapter | Next chapter →