Zero calibration

This was done before the default bot was delivered. There is no need to repeat the operation. Using this feature incorrectly may damage the bot. If your robot is working without abnormality, do not use it. Thank you for your cooperation.

Calibrating the robotic arm is the prerequisite for precise control of the robotic arm, while setting the joint zero point and initializing the motor potential are the basic tasks of subsequent advanced development.

In this chapter, we'll teach you how to calibrate robotic arms as well as test and validate joints.

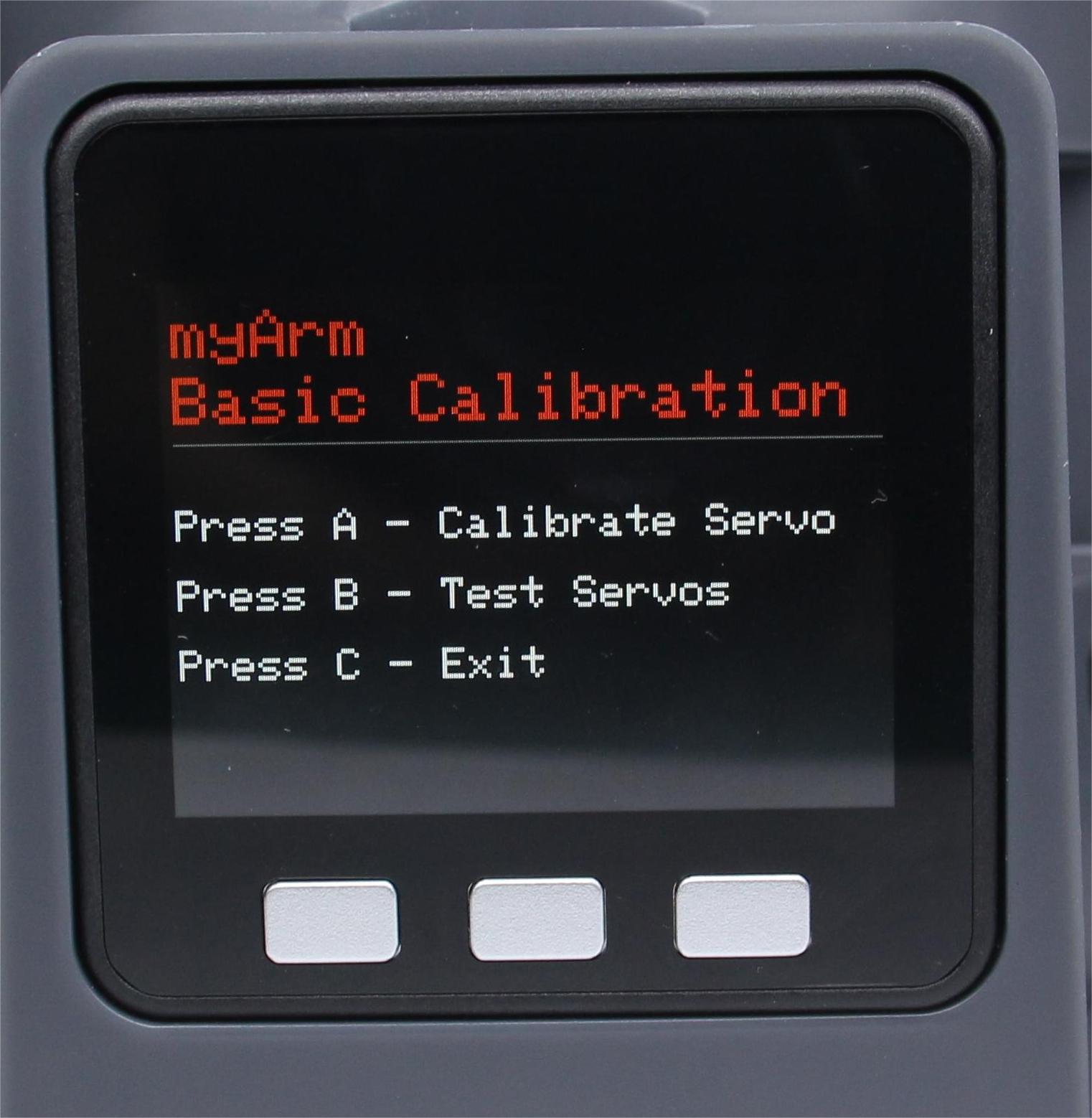

Step 1: Select Calibration, click OK to enter the zero calibration interface.

Step 2: Press the A key to start calibrating the robotic arm.

Step 3: First drag the robotic arm to bring the No. 1 joint to the zero position (zero tick alignment).

Step 3: First drag the robotic arm to bring the No. 1 joint to the zero position (zero tick alignment).

Step 4: Follow the joint serial numbers (1-7) as prompted on the screen, drag the robotic arm to bring each joint to the zero position (zero tick alignment)。

Step 4: Follow the joint serial numbers (1-7) as prompted on the screen, drag the robotic arm to bring each joint to the zero position (zero tick alignment)。

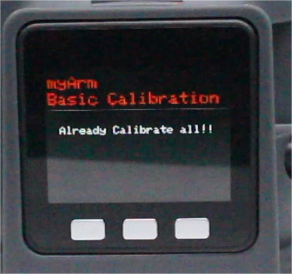

Step 5: Press NEXT in turn to enter the next motor calibration until Already Calibrate all appears!! , that is, the calibration is complete.

Step 6: Press EXIT to exit the calibration.

Note: After successful calibration, the current Angle of each joint will be displayed. The correct Angle information for the zero position is 10° for joint 2, -10° for joint 3, and 0° for all other joints.