myCobotPro Adaptive Gripper

Compatible models: myCobot 320, myCobot Pro 630,myCobot Pro 600

Product Image

Specifications

| Name | myCobotPro Adaptive Gripper Black and White |

|---|---|

| Material | Photosensitive resin + nylon |

| Process technology | 3D printing |

| Gripping range | 0-90 mm |

| Clamping force | 1000 grams |

| Drive mode | Electric drive |

| Gearbox mode | Gear + connecting rod |

| Dimensions | 158x105x55mm |

| Weight | 350 grams |

| Fixing method | Screw fixing |

| Environment requirements | Normal temperature and pressure |

| Control interface | Serial port/IO control |

| Applicable devices | myCobot 320 series, myCobot Pro 630, myCobot Pro 600 |

Used for grabbing objects

Introduction

A manipulator is a robot component that works like a human hand. It has the advantages of complex structure, firm gripping of objects, not easy to fall, and easy operation.

The gripper kit includes gripper connection wires and flanges. The end effector of the manipulator is controlled by a programmable system to realize functions such as grabbing objects and multi-point positioning. The gripper can be used in all development environments, such as ROS, Arduino, Roboflow, etc.

Working principle

- Driven by the motor, the finger surface of the manipulator makes linear reciprocating motion to achieve opening or closing actions. The acceleration and deceleration of the electric manipulator are controllable, the impact on the workpiece is minimal, the positioning point is controllable, and the clamping is controllable.

Applicable objects

Small cubes

Small balls

Long objects

Installation and use

Gripper installation:

Structural installation:

Align the gasket with the hole at the end of the robot arm and tighten it with screws:

Align the screw holes of the gripper with the holes around the gasket and tighten them with thin screws:

- Electrical connection:

Note that the robot arm should be powered off, that is, the green light at the end should not be on when plugging and unplugging. If hot-plugging is performed with power on, there is a risk of damaging the gripper.

- Align the m8 cable with the interface of the robot arm. Note that there is a notch at the interface and a corresponding protrusion on the connecting cable. After confirming the direction, insert it and tighten it:

- Insert the gripper control interface, and also pay attention to the direction of the notch:

Python programming control

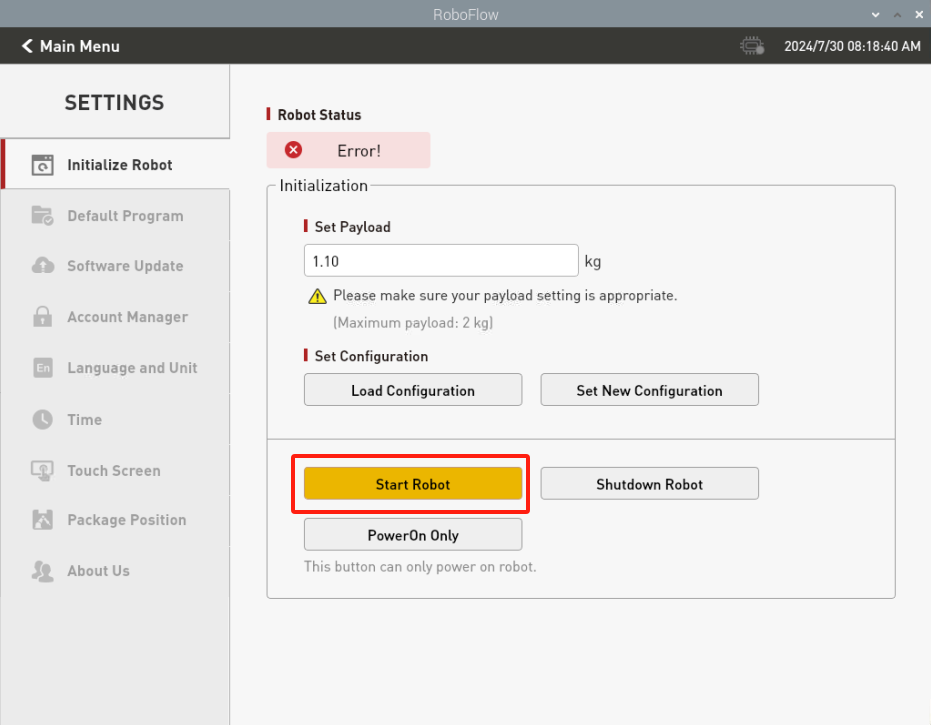

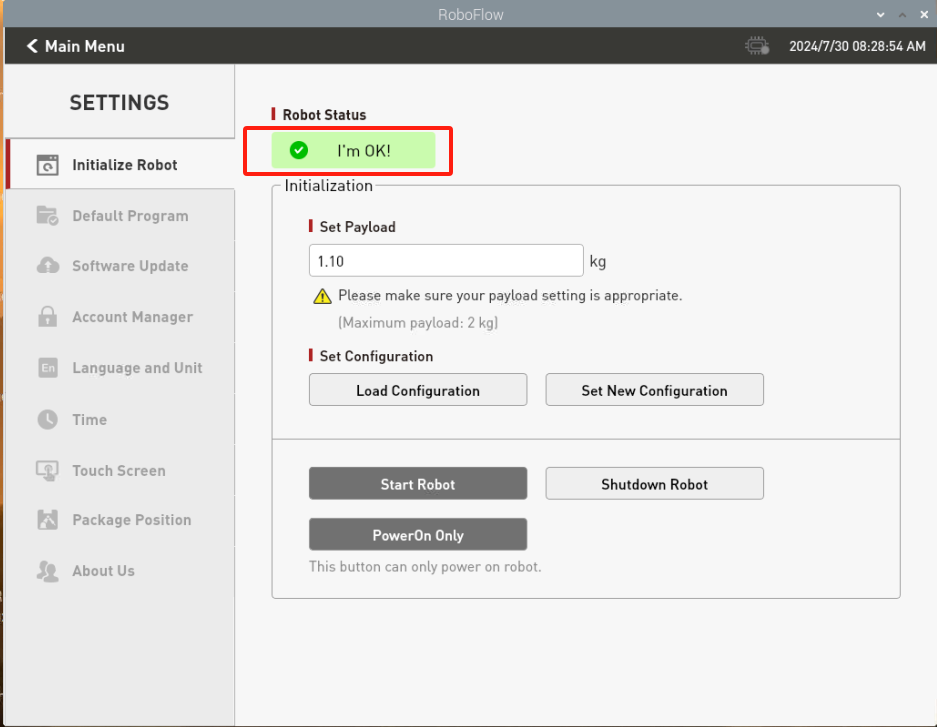

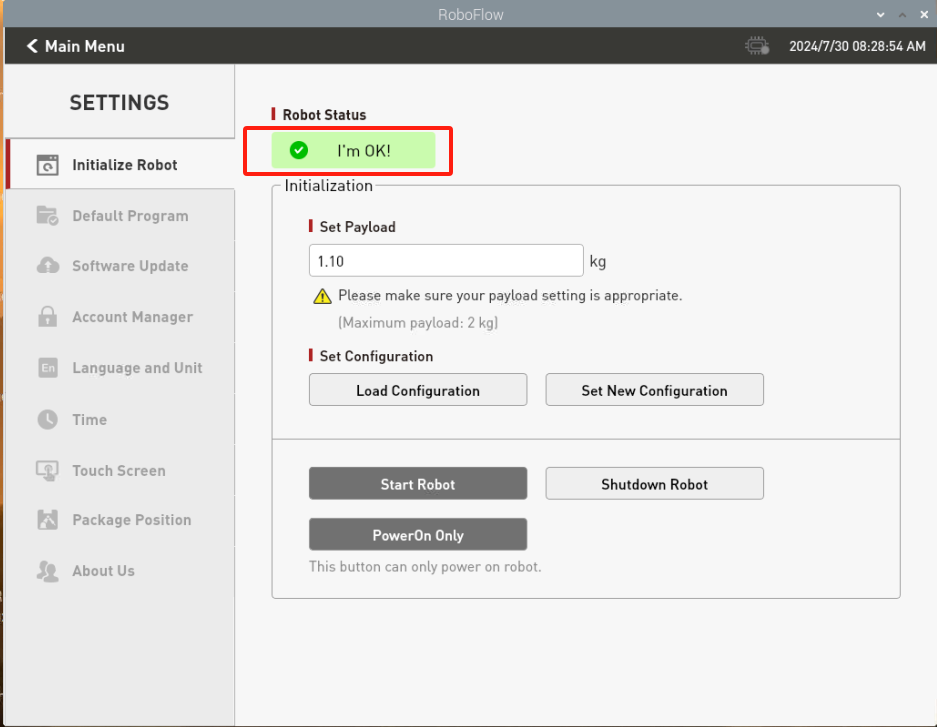

You need to use roboflow to enable the robot first, then run the following python script to test whether the gripper is normal

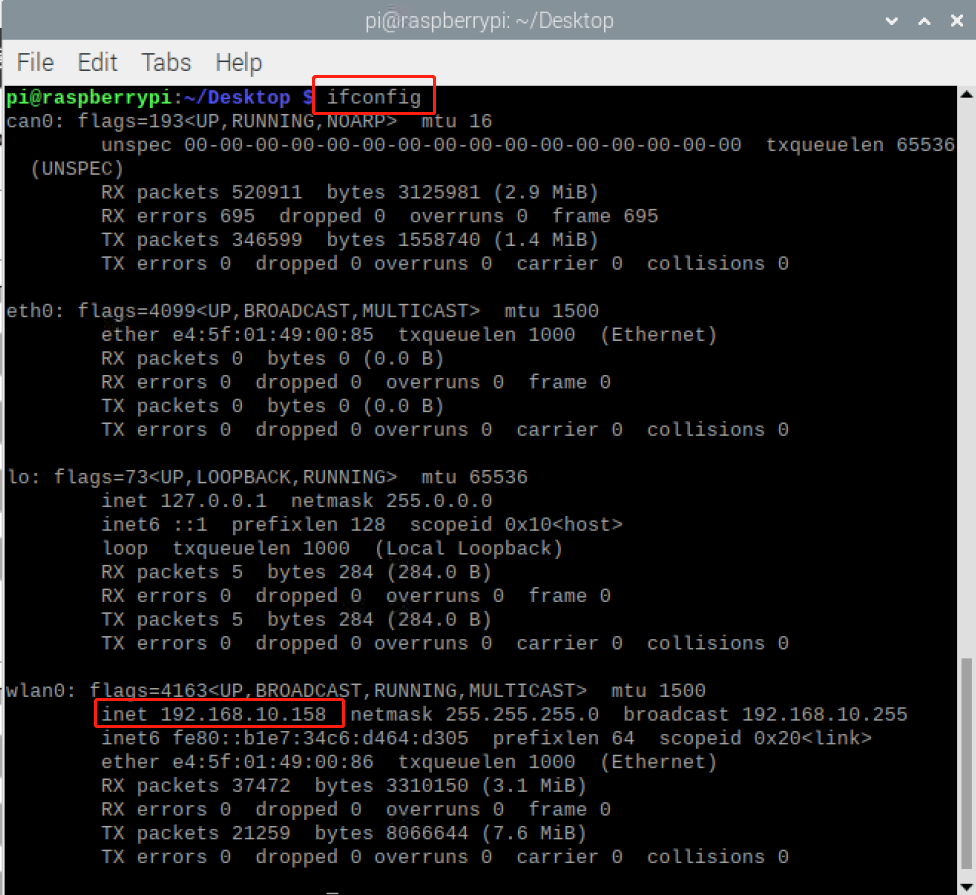

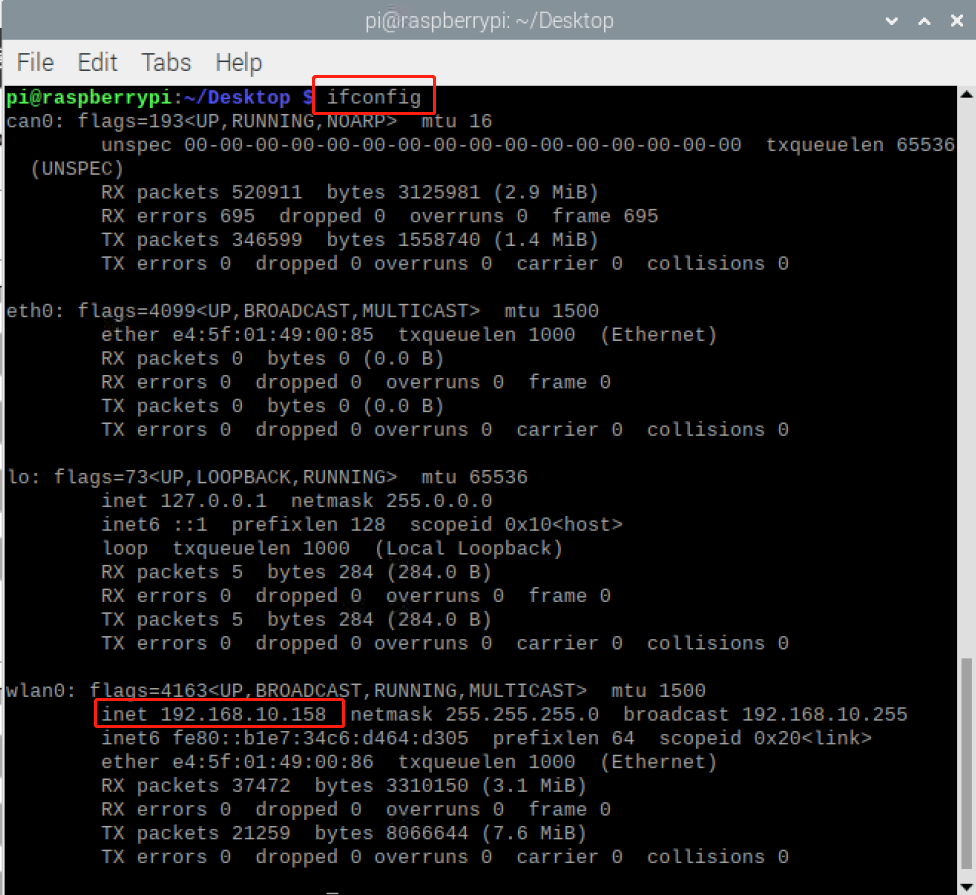

Confirm the IP address of the robot: Enter ifconfig in the terminal to obtain

Python programming control

You need to use roboflow to enable the robot first, then run the following python script to test whether the gripper is normal

Confirm the IP address of the robot: Enter ifconfig in the terminal to obtain

IO control mode

from pymycobot import ElephantRobot

import time

# Change the ip to the real-time ip of the P600 Raspberry Pi

elephant_client = ElephantRobot("192.168.10.158", 5001)

# Necessary commands to start the robot

elephant_client.start_client()

time.sleep(1)

elephant_client.set_gripper_mode(1)

time.sleep(1)

#elephant_client.power_off()#When changing the IO mode from gripper to gripper, you need to shut down the machine and restart the robot. If you only use gripper to gripper mode, you do not need to shut down the robot

elephant_client.power_off()

time.sleep(3)

elephant_client.state_off()

time.sleep(3)

elephant_client.power_on()

time.sleep(3)

elephant_client.state_on()

time.sleep(3)

elephant_client.set_digital_out(16, 0) # IO restores low level

time.sleep(1)

elephant_client.set_digital_out(17, 0) # IO restores low level

time.sleep(1)

# IO mode

# Gripper full open and full closed control code. Note that when the gripper is transparently switched to IO mode, you need to shut down the machine and restart the robot once before switching back to the gripper IO mode

for i in range(3):

elephant_client.set_digital_out(16, 1) # Close the gripper

time.sleep(1)

elephant_client.set_digital_out(17, 0) # IO restores low level

time.sleep(1)

elephant_client.set_digital_out(16, 0) #IO restores low level

time.sleep(1)

elephant_client.set_digital_out(17, 1) # Open the gripper

time.sleep(1)

elephant_client.set_digital_out(16, 0) # IO restores low level

time.sleep(1)

elephant_client.set_digital_out(17, 0) # IO returns to low level

time.sleep(1)

Transparent transmission mode

from pymycobot import ElephantRobot

import time

# Change the IP address to the real IP address of the P600 Raspberry Pi

elephant_client = ElephantRobot("192.168.10.158", 5001)

# Necessary commands to start the robot

elephant_client.start_client()

time.sleep(1)

elephant_client.set_gripper_mode(0)

time.sleep(1)

# elephant_client.power_off()#When changing the IO mode of the gripper through transmission, you need to shut down the machine and restart the robot once. If you only use the gripper through transmission mode, you do not need to shut down the robot

elephant_client.state_off()

time.sleep(3)

elephant_client.power_on()

time.sleep(3)

elephant_client.state_on()

time.sleep(3)

#Transparent transmission mode

for i in range(3):

elephant_client.set_gripper_value(26,20)

time.sleep(1)

elephant_client.set_gripper_value(86,20)

time.sleep(1)

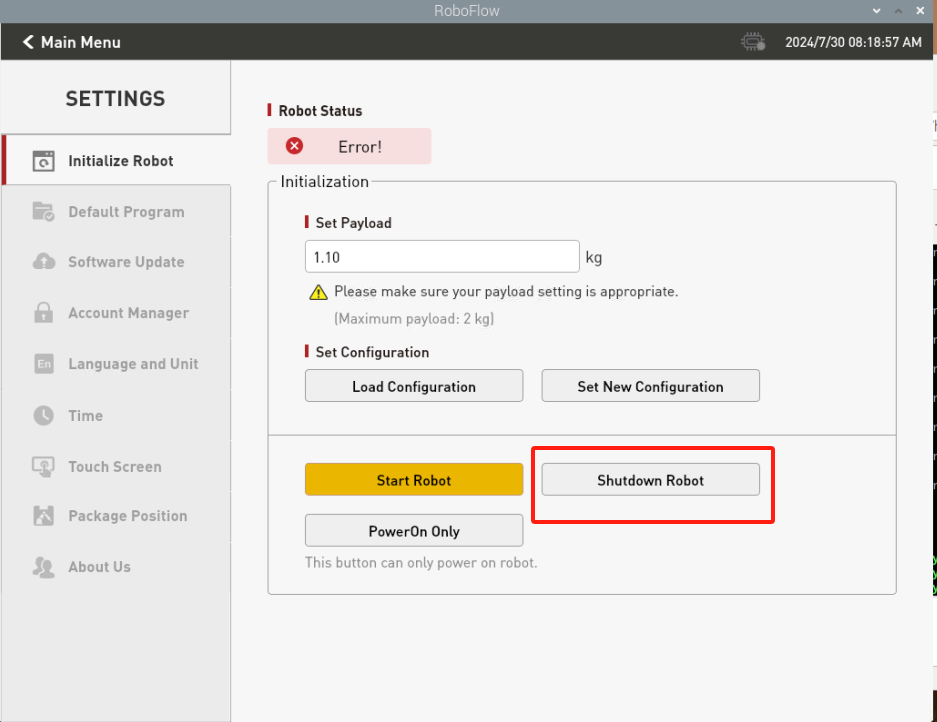

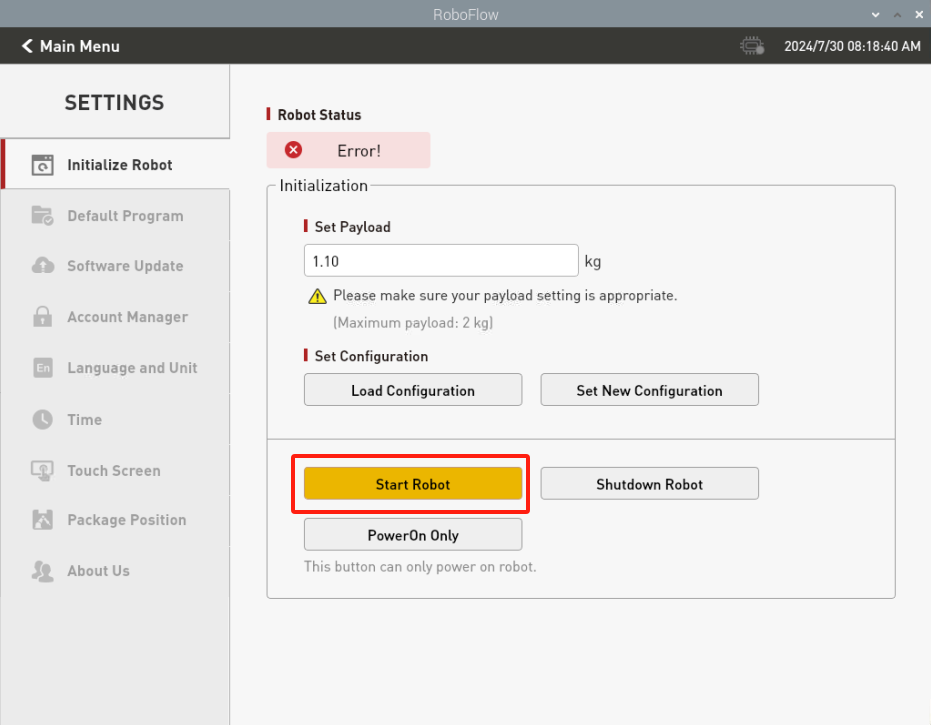

Gripper zero position calibration

The gripper has been zero-calibrated before leaving the factory. If the gripper's stroke is incorrect, you can calibrate it according to the following steps

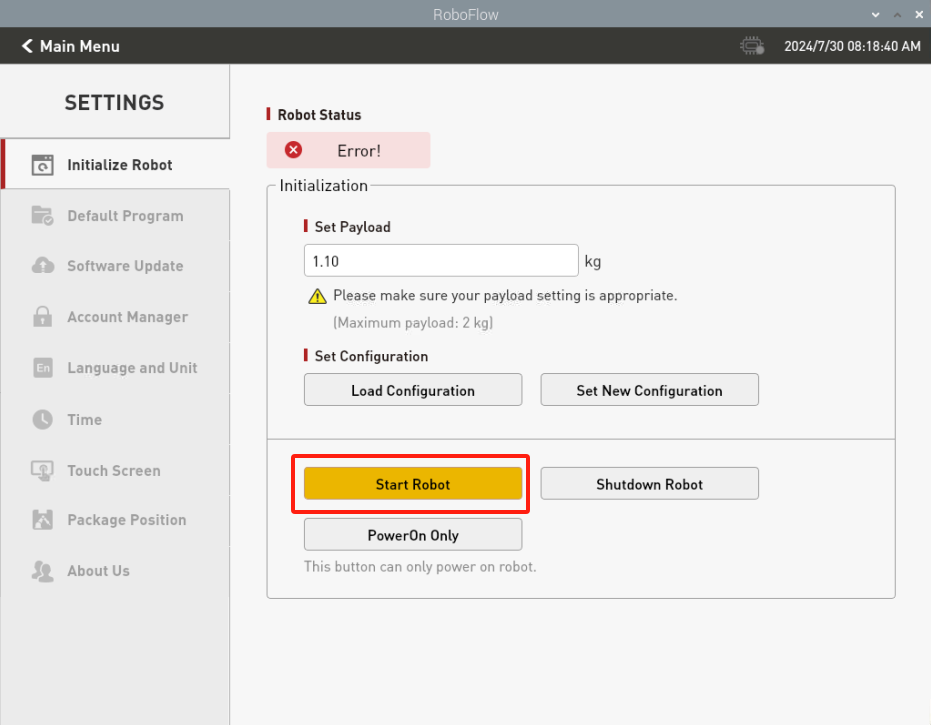

First turn off the robot in roboflow, and manually open the gripper to the maximum

Then start the robot

Then execute the following script

from pymycobot import ElephantRobot

import time

# Change the IP address to the real IP address of the P600 Raspberry Pi

elephant_client = ElephantRobot("192.168.10.158", 5001)

# Necessary commands to start the robot

elephant_client.start_client()

time.sleep(1)

elephant_client.set_gripper_mode(0)

time.sleep(1)

elephant_client.set_gripper_calibrate()

time.sleep(1)