Flexible Gripper Pro

Compatible models: myCobot 320, myCobot Pro 630

Product Icon

Specifications

Gripper

| Picture | |

|---|---|

| Material | Metal |

| clamping rangeclamp size | 36-136mm |

| clamp force | Vertical 600g wrap 1080g |

| Repeatability precision | 0.5 mm |

| service life lifetime | 1 year |

| drive mode drive | pneumatic |

| Transmission modetransmission | deformation |

| size | 170x128x195mm |

| weightweight | 365 grams |

| Fixed method fixed | screw fixed |

| Use environment requirements | Temperature and pressure |

| control interface control | SAC40A Pneumatic Controller |

| Applicable equipment | ER myCobot 320 series, ER myCobot Pro 600 |

Controller

| Picture | |

|---|---|

| Power | 24V 1.5A |

| Controller | IO |

| Air Source Pressure | > 0.4 MPA |

| Flow Rate | > 40 L/MIN |

| IO | |

| Value State | IN1: HIGH & IN2: LOW = Close Gripper IN1: LOW & IN2: HIGH = Open Gripper Caution ⚠️: When using IO control, ensure the three-position toggle switch above is set to the middle position. |

| 船型开关 | The term "船型开关" translates to "toggle switch," specifically referring to a three-position toggle switch. |

| 正压 | Gripper Close |

| 负压 | Gripper Open |

Use for Gripping Objects

Introduction

Traditional industrial suction cups need to absorb the flat surface of the material. In more and more working conditions, the suction surface is easy to damage the panel or components. The soft-touch gripper pinches the edge to grab the panel easily and without trace or damage, ensuring that the product surface is flawless. , Improve the yield rate.

The modular design of the soft-touch gripper is light in weight and can be freely arranged and combined according to the size of the panel.

The clamping force of traditional cylinders is generally large, and the force is difficult to control. The edge of the clamping panel is easy to pinch and warp. The single-finger clamping force of the flexible gripper is precise and controllable, and will not pinch fragile workpieces.

working principle

- The flexible gripper is an innovative bionic flexible gripper developed by researchers to imitate the shape of the starfish's arms and legs. The "fingers" of the soft claw are made of flexible polymer silicone material, which can be bent and deformed by inflation. It can adaptively cover the target object like a starfish, and can complete the flexible and non-destructive grasping of special-shaped and fragile objects. Pick.

Applicable object

- Objects of any shape within a reasonable size

Mall link:

How to use

1 Installing:

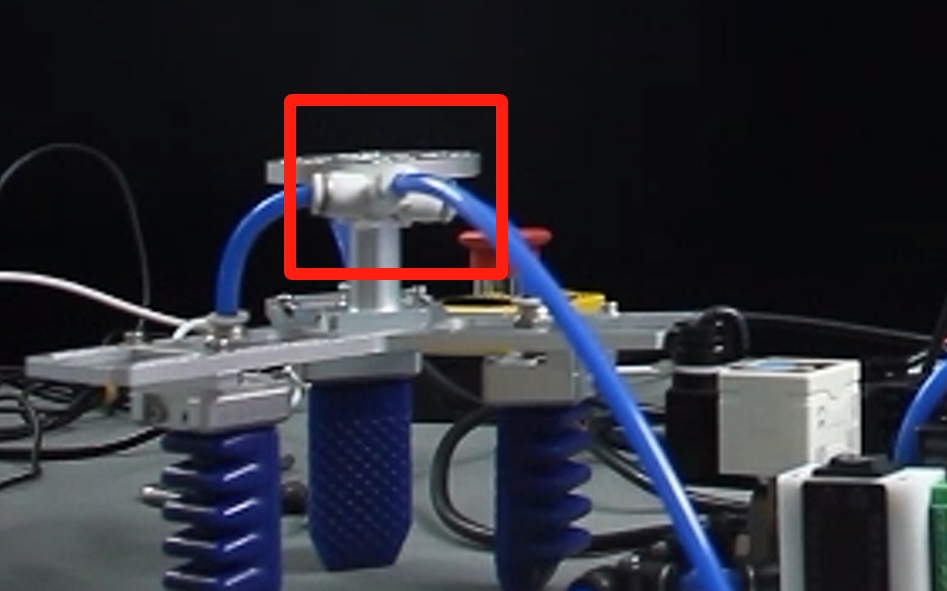

Pneumatic Circuit Connection and Pressure Adjustment: Start by adjusting the positive pressure before connecting to the soft mechanical grip (the outlet can temporarily be blocked with a fingertip, ensure the positive pressure is strictly less than 100KPA to avoid potential finger injury).

For connecting and adjusting the pneumatic circuit: First, set the positive pressure before connecting to a soft mechanical grip. Temporarily block the outlet with a fingertip to prevent air escape, ensuring the positive pressure is strictly below 100KPA to avoid potential injury to the finger.

Connect to Air Source: Attach the air source to port 6 (inlet), ensuring the pressure is above 0.4MPA and flow exceeds 40L/MIN.

- Connect Soft Mechanical Grip: Link the soft mechanical grip to port 4 (outlet).

- Power Up: Supply power to connection 5.

- Adjust Positive Pressure: Use the toggle switch to select positive pressure. Adjust the regulator as per the gauge until desired pressure is reached.

- Switch to Negative Pressure: For negative pressure adjustment, pull up the regulator cap, turn to set, then push down to lock.

Special Reminder ⚠️: Regarding pressure maintenance, both positive and negative pressures can be maintained after 0.5 seconds of activation, allowing the mechanical grip to retain its preset pressure. This approach is energy-efficient, especially since maintaining negative pressure continuously consumes more air. Additionally, it prevents the loss of grip on objects in case of unexpected power or air supply cut-offs, ensuring operational reliability.

Installation and use

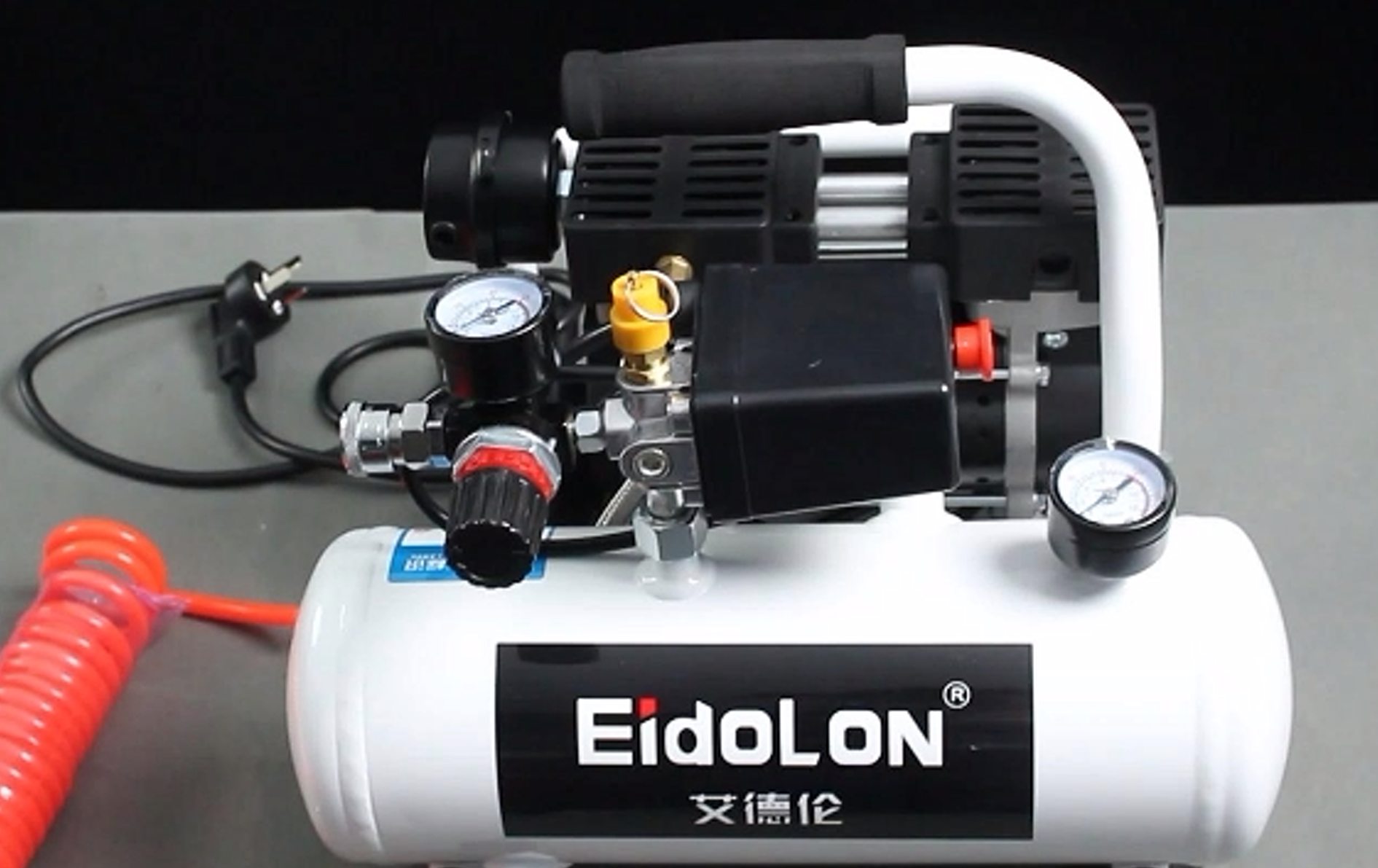

It needs to be used with an air compressor:

Insert the black plug into the row of plugs;

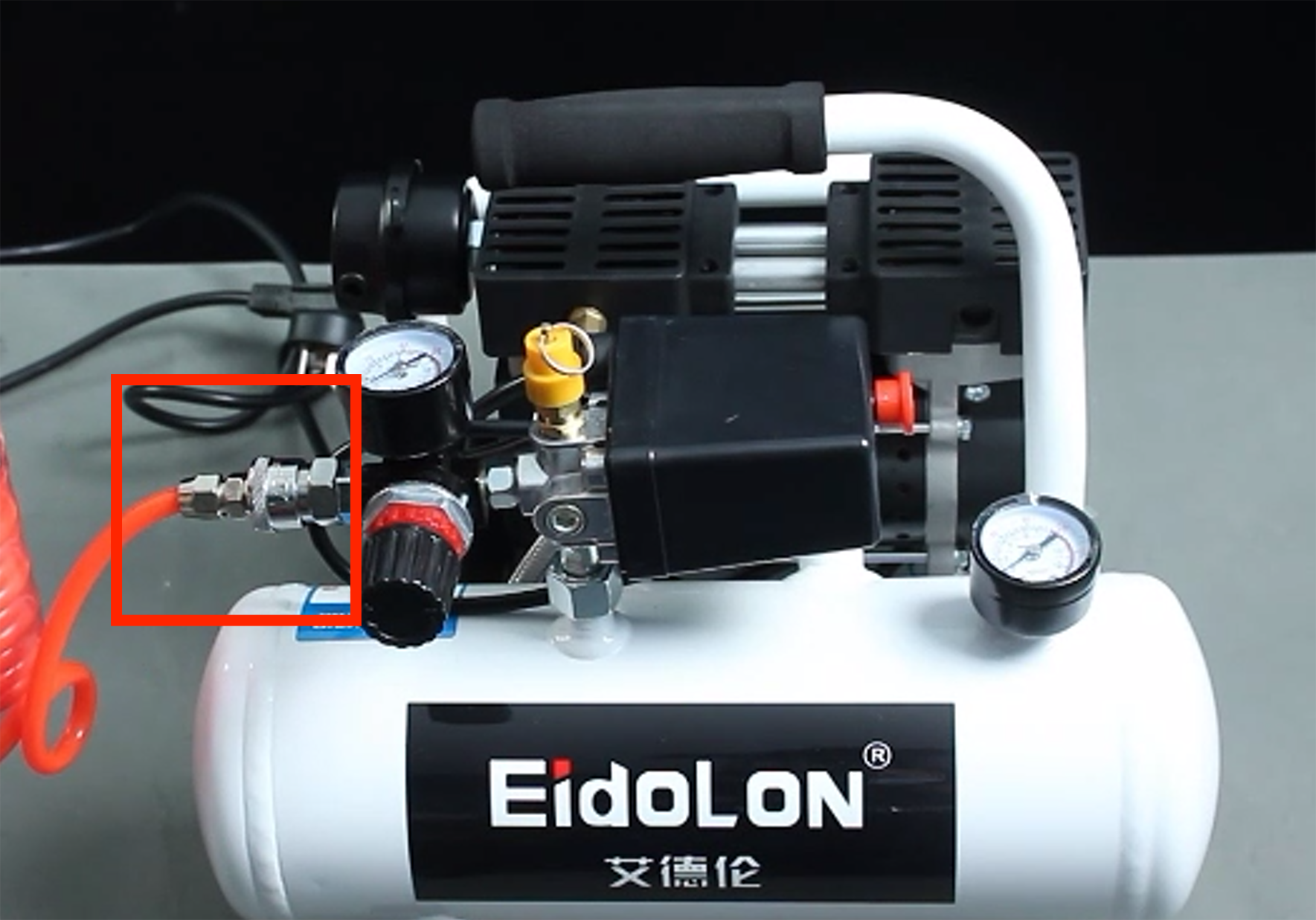

Insert the matching red hose into the connector on the machine:

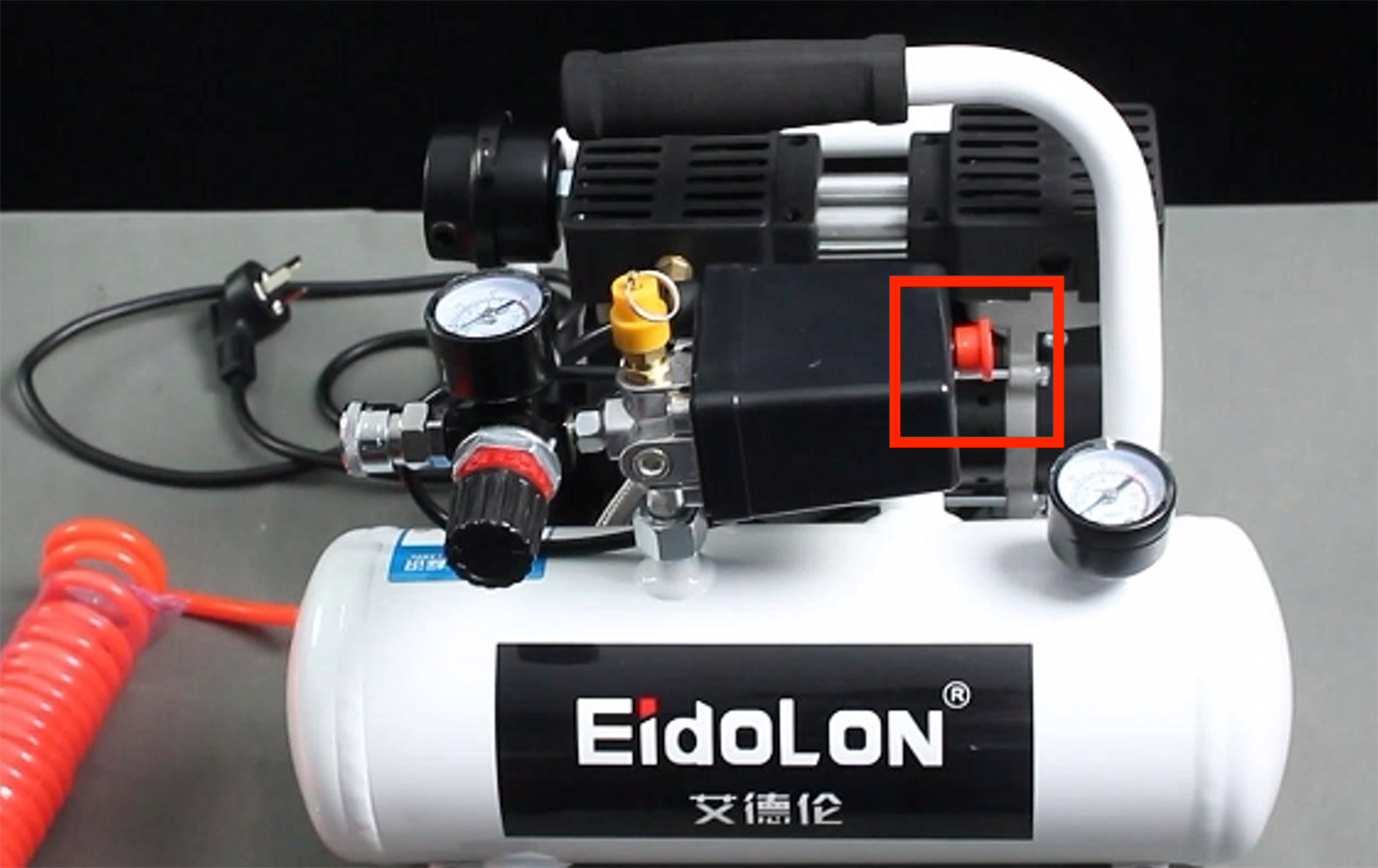

- The red button is the on/off switch, pulling it outwards turns it on, pressing it back turns the machine off:

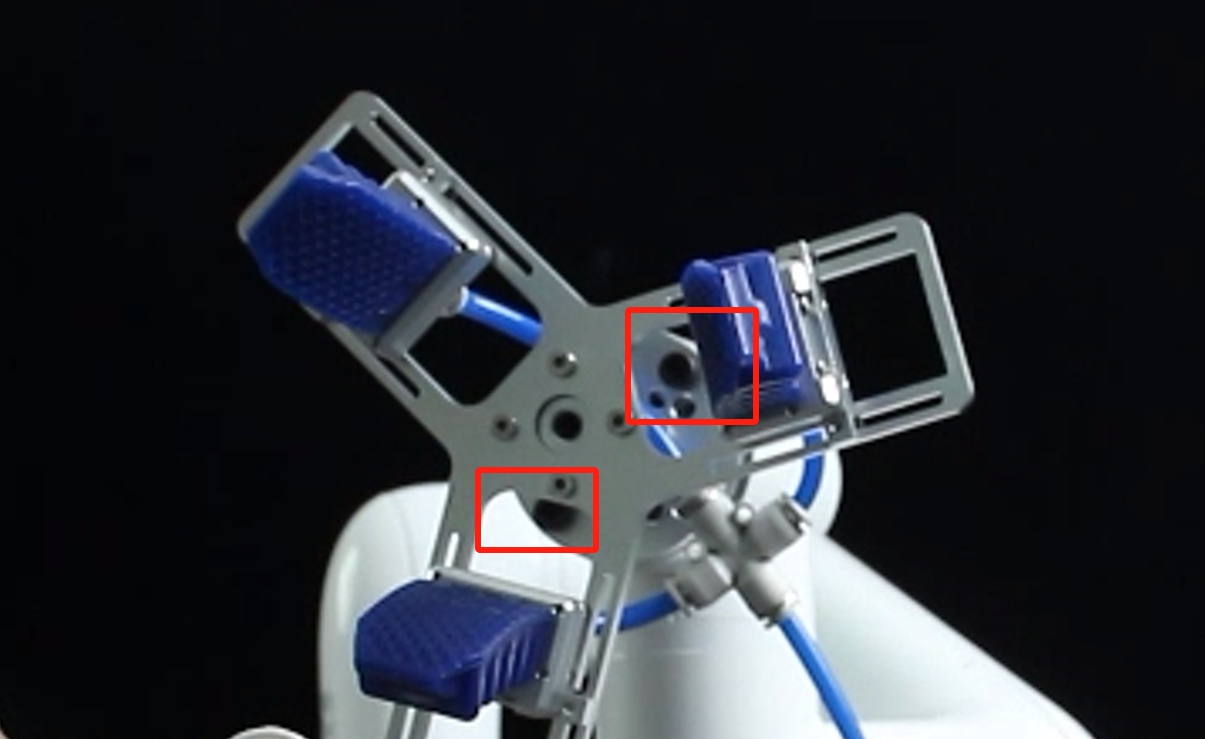

gripper mounted:

</video>

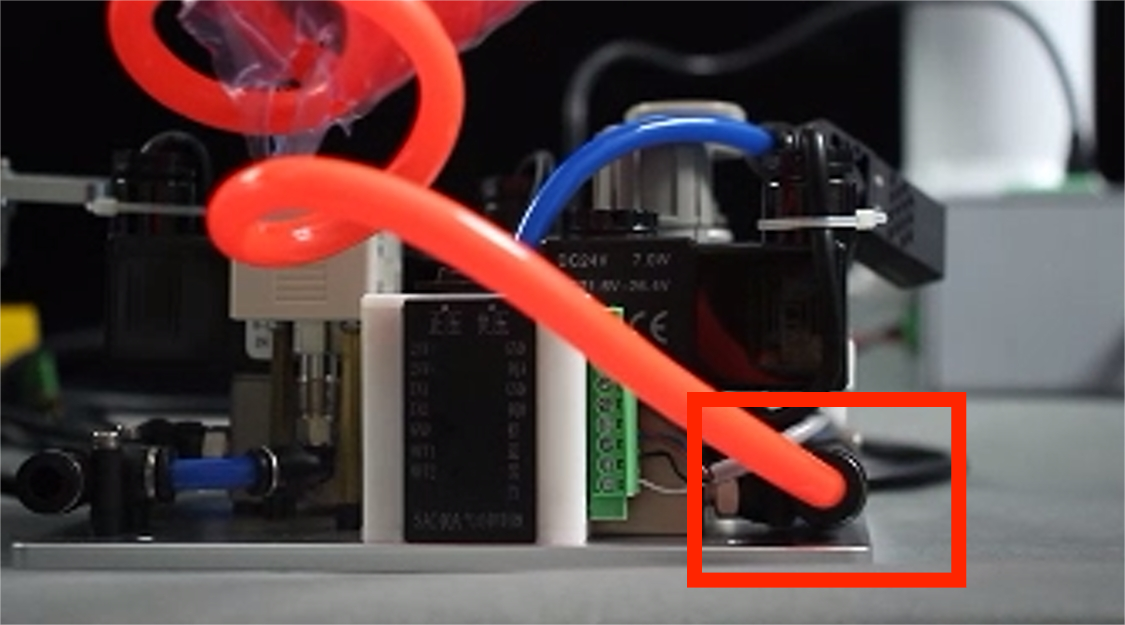

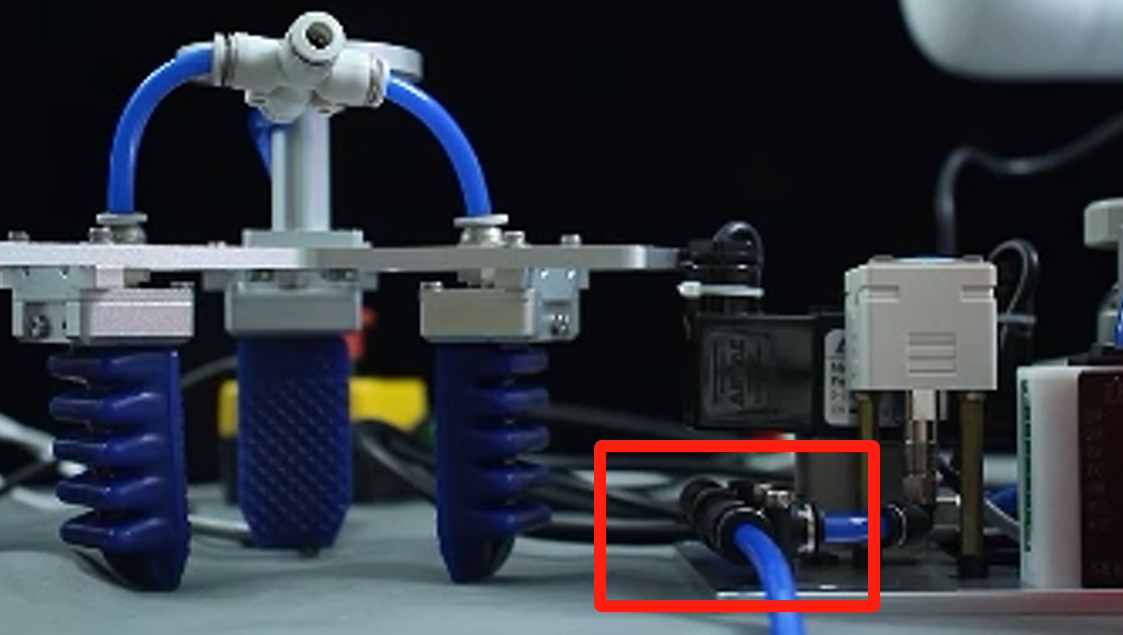

- Connect the other end of the red hose from the air compressor to the connector on the pneumatic controller:

- Use the blue hose that comes with the flexible gripper to connect the gripper to the pneumatic controller:

- Attach the flexible gripper to the end of the arm with the matching screws:

- Connect the other end of the red hose from the air compressor to the connector on the pneumatic controller:

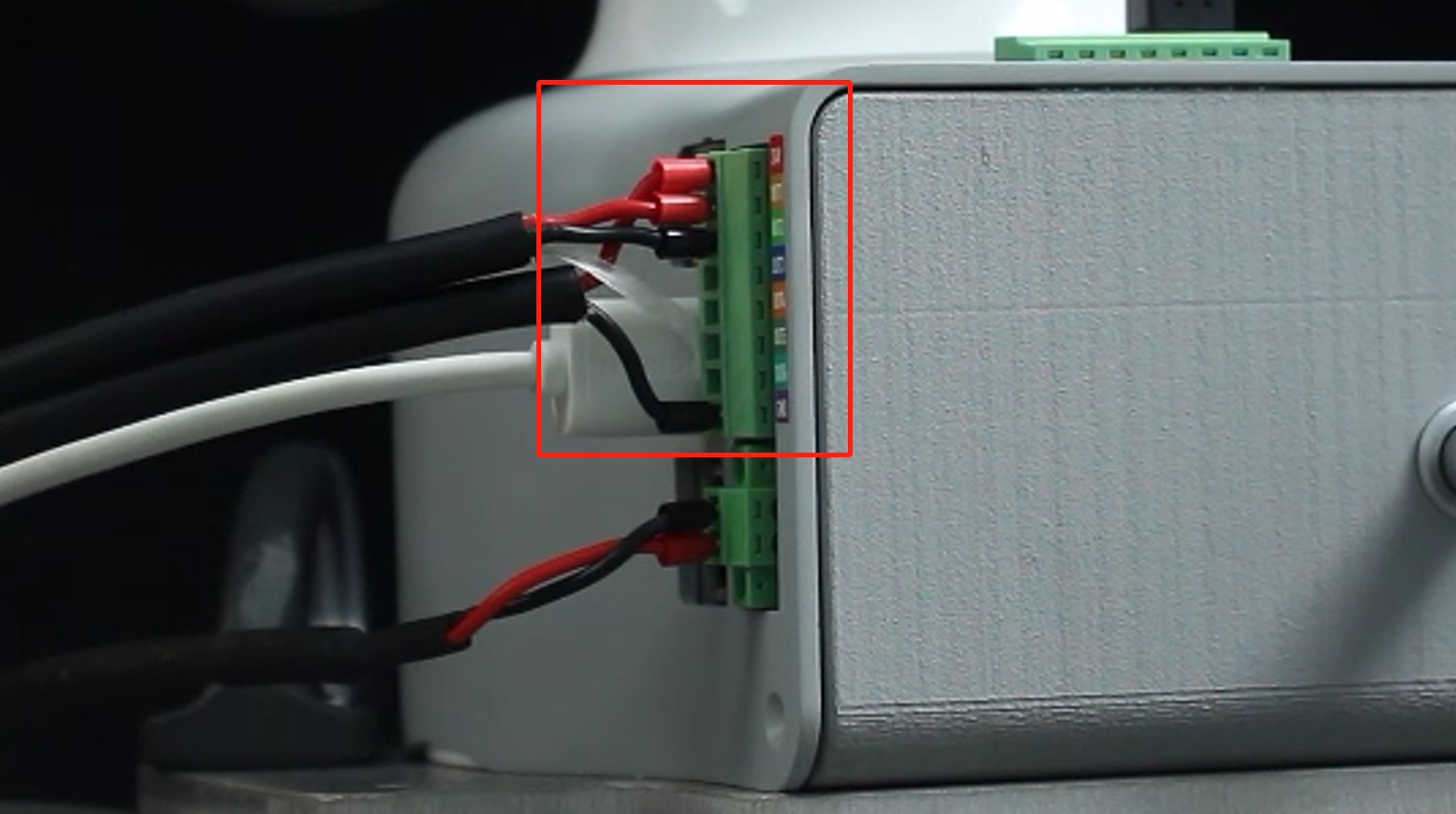

Electrical Connections:

Two connection cables are issued, one for power and one for control.

At the base of the robot arm, for the power supply, connect the red wire to the 24V connector and the black wire to the GND connector. For the control wires, connect red to OUT1 and black to OUT2:

- Pneumatic controller terminal, power supply wire red connects to pneumatic controller 24V, black connects to pneumatic controller GND, control wire red connects to IN1, black connects to IN2:

Be careful to connect to the "Positive Voltage" side, if the power supply is successful the display will light up. You can test the connection manually to see if it is working properly by switching the air compressor on and pressing the button on the pneumatic controller, pressing it to the left (positive pressure) will contract the gripper and pressing it to the right (negative pressure) will open the gripper.

Software-driven testing:

To test if the gripper are available after installation, use myBlockly. myblockly download

- After confirming that the structural and electrical connections are complete, start the arm and open the myblockly software when the graphical interface appears.

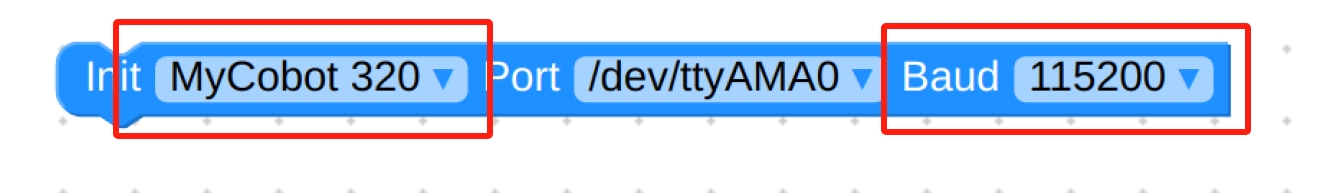

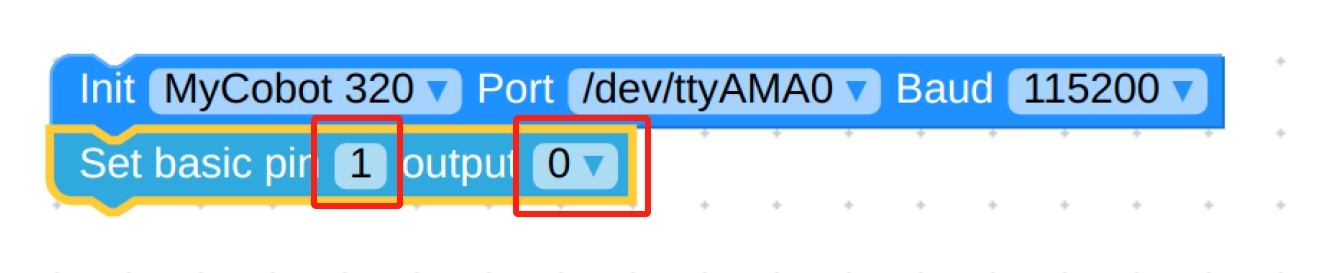

- Modify the baud rate to 115200:

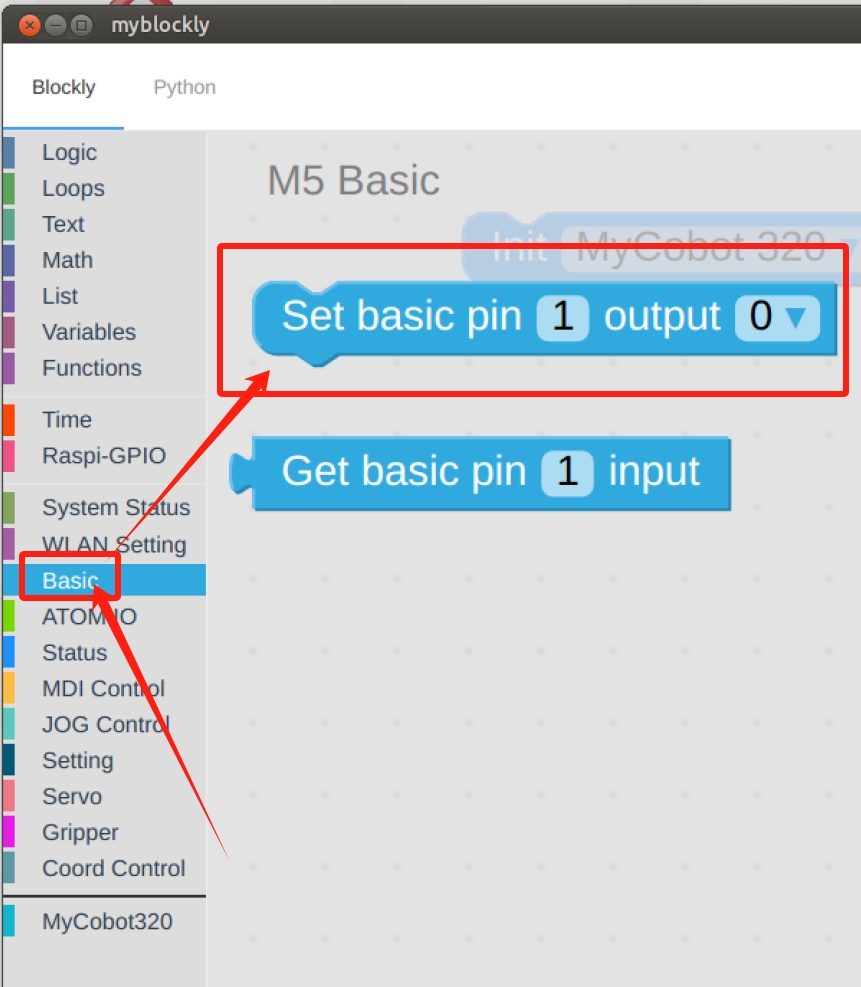

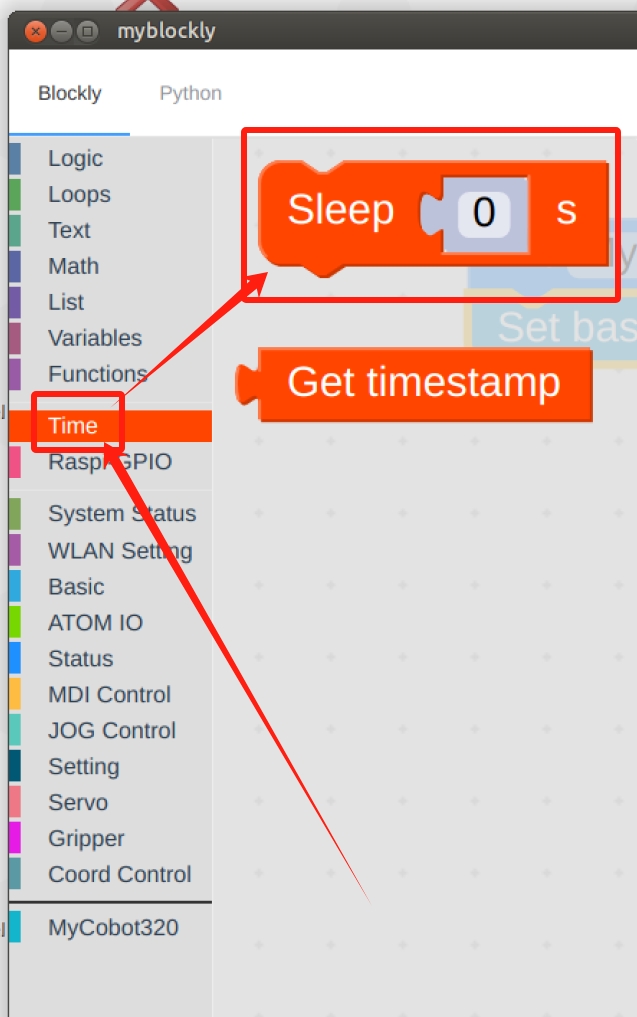

- Find

Basein the list on the left and select theSet Pin Outmodule:

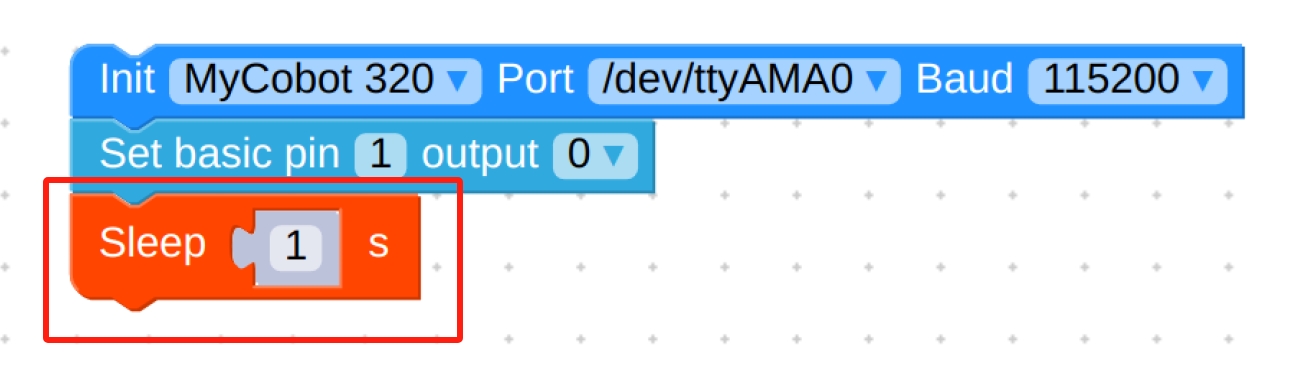

- Set

pin numberto1andoutputto0:

- Find

Timeand select theSleepmodule:

- Set the time as desired, here it is set to

1s:

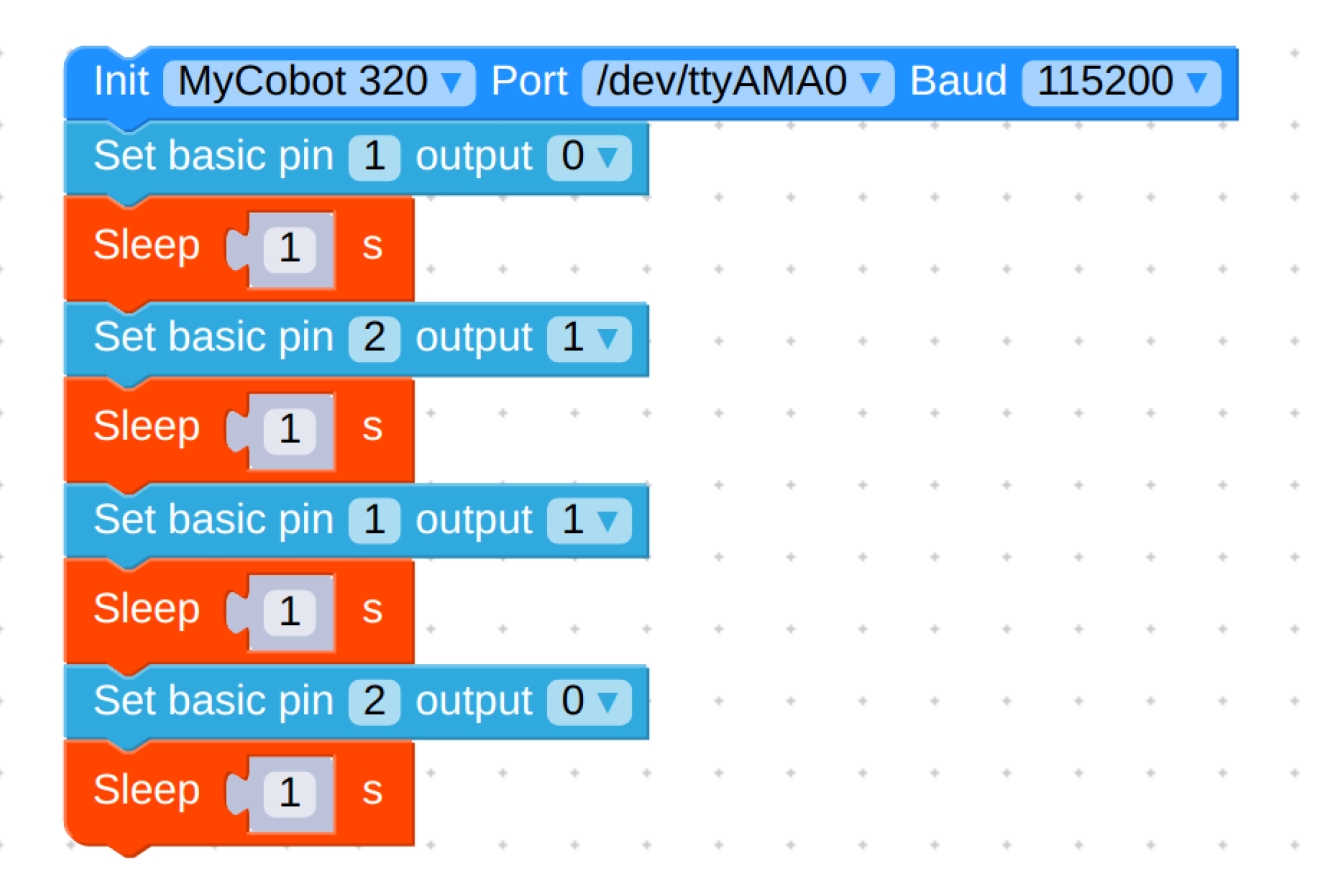

- Repeat the above steps for the final setup as follows:

Final code:

from pymycobot.mycobot import MyCobot import time mc = MyCobot('/dev/ttyAMA0', 115200) mc.set_basic_output(1, 0) time.sleep(1) mc.set_basic_output(2, 1) time.sleep(1) mc.set_basic_output(1, 1) time.sleep(1) mc.set_basic_output(2, 0) time.sleep(1)- Click on the green run button in the top right corner to see the gripper close-open once.

- After confirming that the structural and electrical connections are complete, start the arm and open the myblockly software when the graphical interface appears.

Programming Development:

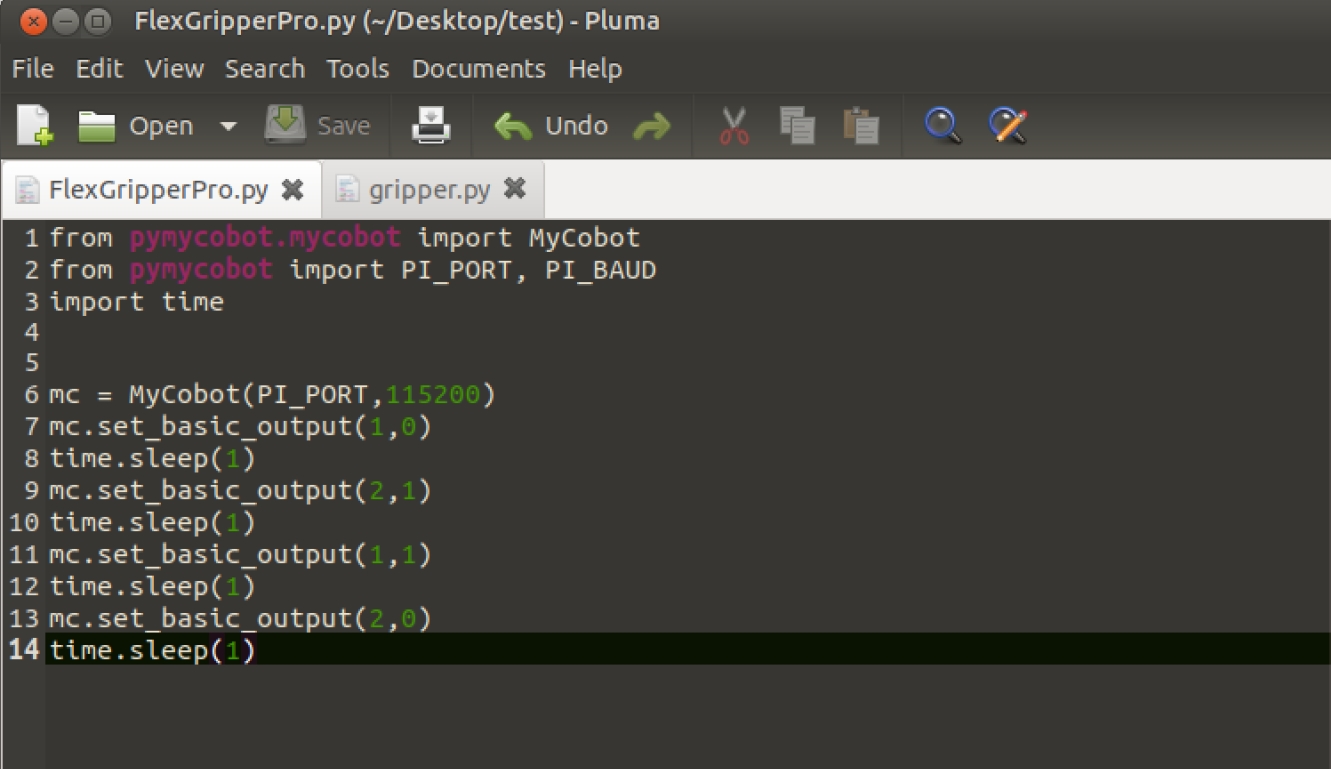

Programming the gripper using python python environment download

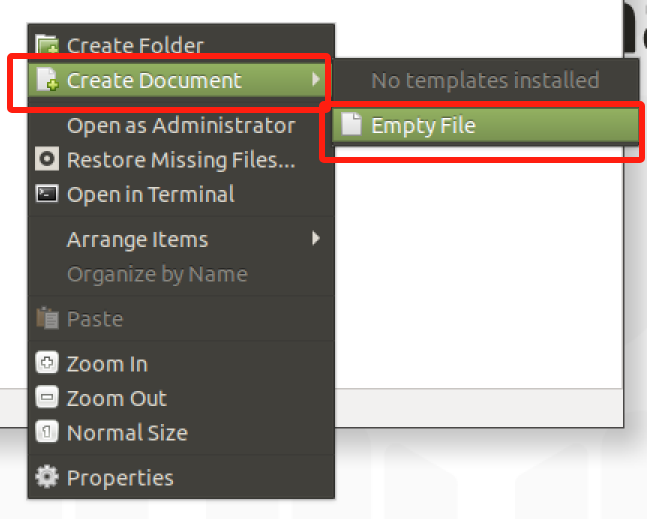

Create a new python file:

Right click on the desired file path to create a new python file:

The file name can be changed as needed

Perform function programming:

The code is as follows:

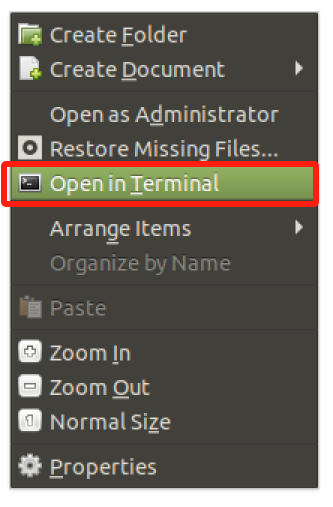

from pymycobot.mycobot import MyCobot import time # Initialise a MyCobot object mc = MyCobot("COM3", 115200) # Controls gripper closed-open: # Using the gripper status interface 0 is open, 1 is closed mc.set_basic_output(1, 0) time.sleep(1) mc.set_basic_output(2, 1) time.sleep(1) mc.set_basic_output(1, 1) time.sleep(1) mc.set_basic_output(2, 0) time.sleep(1) # For more information on using the interface, see the python API.Save the file and close it, right-click on an empty space in the folder to open a command line terminal

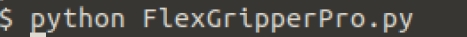

Input:

python FlexGripperPro.py

gripper can be seen closed-open