First-time self-check- Machine Joint Function Verification

Attention: When starting up the robotic arm, please ensure that it is not in a curled-up position or in a posture where joints are touching. It is recommended to start the robotic arm with the posture shown in the following diagram:

The steps for joint control are as follows:

1. Hardware Connection:

For MyCobot 280 and Mech 270 series robotic arms, ensure that the power adapter and USB data cable are connected.

For the mycobot320 series machines, please ensure that the power adapter, USB data cable, and emergency stop switch are connected. Make sure the emergency stop switch is in the released state. Failure to use the emergency stop switch correctly will result in the mycobot320 not functioning properly. Please refer to the diagram below for the emergency stop switch:

2. Software Environment Installation and Configuration:

For M5 version robots, you need to install Python, the PyMyCobot library, and USB serial drivers. Please refer to the Python usage section in the Gitbook for specific instructions.

For PI or JN version robots, there is no need to install and configure the usage environment separately. The factory provides pre-configured images in the robot system, which can be directly used for running robotic arm usage examples.

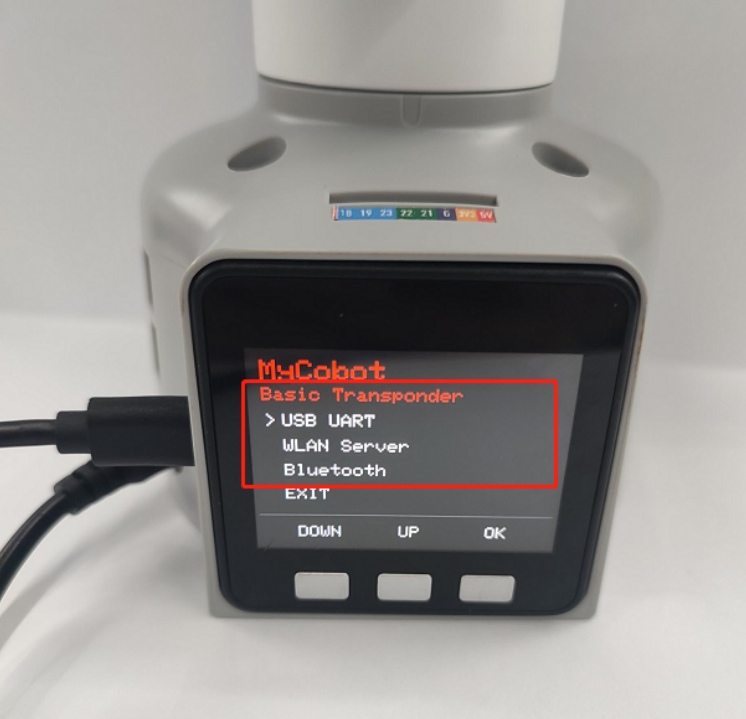

3. Select the Correct Communication Method:

Before using each communication method, make sure to adjust the M5's LCD screen to the corresponding mode and maintain this communication status in order to control the robotic arm properly. This step is only applicable to the M5 version; other versions of the robot can skip step 3.

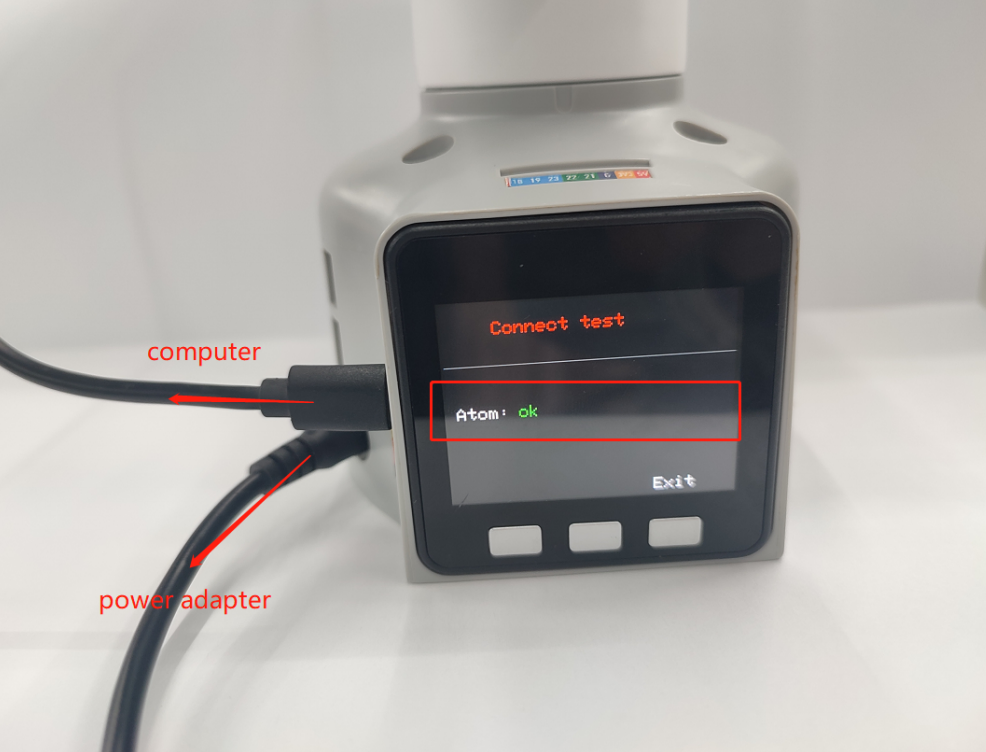

When using development methods such as myblockly, Python, ROS, etc., with the M5 robotic arm, ensure that the M5's LCD screen stays on the "Atom: ok" interface, as shown in the figure below:

Please note that when the screen displays "Atom: no", you need to restart the machine by powering it off and then on again. Afterward, follow the self-check steps related to hardware for "joints unable to lock" as described in this document.

4. Using USB Communication as an Example, Verify Joint Motion Python Source Code:

Note that using USB serial open mode requires selecting the corresponding serial port and baud rate to ensure normal communication between the robotic arm and the computer, thereby controlling the robotic arm normally.

Below is the corresponding information for the model, serial port, and baud rate:

| Common Problems and Solutions for Robotic Arms | Serial Port | Baud Rate |

|---|---|---|

| 260 M5 | Win: COM; Linux: /dev/ttyUSB; | 115200 |

| 270 M5 | Win: COM; Linux: /dev/ttyUSB; | 115200 |

| 280 M5 | Win: COM; Linux: /dev/ttyUSB; | 115200 |

| 320 M5 | Win: COM; Linux: /dev/ttyUSB; | 115200 |

| 260 PI | /dev/ttyAMA0 | 1000000 |

| 270 PI | /dev/ttyAMA0 | 1000000 |

| 280 PI | /dev/ttyAMA0 | 1000000 |

| 320 PI | /dev/ttyAMA0 | 115200 |

| 280 Jetson Nano | /dev/ttyTHS1 | 1000000 |

Note: When selecting the COM port for M5 series machines, it is necessary to choose based on the port number recognized by the current personal computer in real-time. This is because the COM port number recognized by each person's computer may vary and is not fixed. For specific selection methods, please refer to the answer to "Q: Why am I refused connection when selecting a certain COM port? Or, how do I find the corresponding COM port?" in this document.

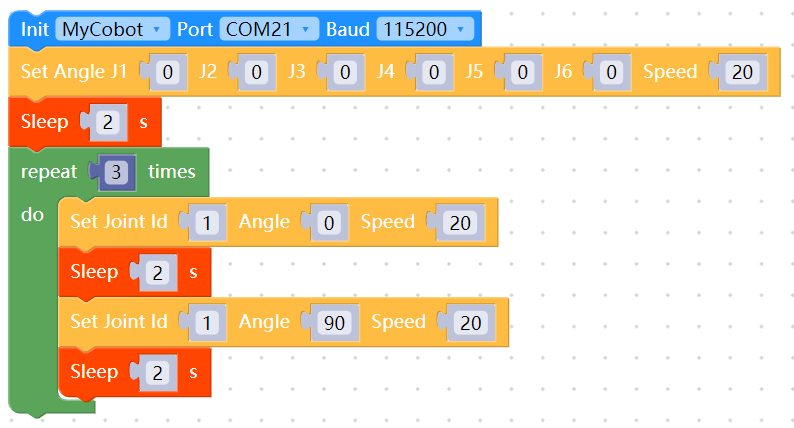

Robotic Arm Joint Motion MyBlockly Source Code:

When you observe the effect of joint 1 of the robotic arm cyclically moving from 0 to 90 degrees three times, it indicates that joint 1 of the robotic arm responds normally. You can try changing the joint ID to test other joints and gradually learn to use other examples in GitBook or utilize the robotic arm for various interesting tasks!

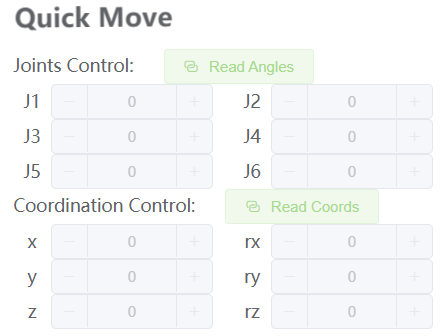

It's worth mentioning that if you are not familiar with the code block development method of MyBlockly, there is a relatively quick way to verify joints: use the MyBlockly Quick Move Tool for simple joint motion control. For specific usage, please refer to the link below:

https://drive.google.com/file/d/1pDR-WBjkGrLcRdeshDmAMIWbEpu_jsJW/view?usp=sharing

Robotic Arm Joint Motion Source Code:

# The motion effect is the robotic arm revolving around the zero position, with joints 1-6 moving ±20 degrees one by one

import time

from pymycobot.mycobot import MyCobot

if __name__ == "__main__":

cobot = MyCobot('com22', 115200) # Choose the corresponding port and baud rate according to the model of the robot

cobot.set_fresh_mode(1)

cobot.send_angles([0, 0, 0, 0, 0, 0], 20)

time.sleep(2)

print("start")

for i in range(1, 7):

cobot.send_angle(i, -30, 20)

time.sleep(2)

cobot.send_angle(i, 30, 20)

time.sleep(2)

cobot.send_angle(i, 0, 20)

time.sleep(2)

When you see the motion effect of the robotic arm revolving around the zero position, with joints 1-6 moving ±20 degrees, it indicates that joints 1-6 respond normally. You can gradually learn to use other examples in the Gitbook or use the robotic arm to do various interesting things!

If you don't see the corresponding effect when executing the example, please refer to the following common problem-solving solutions. Also, make sure you have checked the following 5 points before contacting technical support:

- Is the robotic arm able to lock normally after power-on? If it cannot lock, please refer to the hardware-related issue: "Q: How to solve the problem of the robotic arm not locking after power-on?" for troubleshooting.

- If you are using an M5 series robotic arm,is the computer connected to the USB port on the side of the M5stack via type-c?

- If you are using an M5 series robotic arm,is the LCD screen currently staying on the "Atom: ok" interface?

- If you are using a 320 series product, please ensure that your emergency stop switch is connected and in the released state.

- Are there any error messages when running the code?

Please describe the details of your usage as much as possible, and if possible, provide an operation video, which will help to quickly analyze and locate the problem. Thank you in advance!