机械臂的控制

注意:pymycobot 驱动库的版本必须大于4.0.0

使用前准备

在使用案例功能之前,请先确认以下硬件和环境准备齐全:

硬件设备

- MyCobot Pro 450 机械臂

- 网线(用于连接机械臂与电脑)

- 电源适配器

- 急停开关(确保安全操作)

软件与环境

- 已安装 Python 3.6 及以上版本

- 已安装

pymycobot库(通过pip install pymycobot终端命令安装) - 确保 MyCobot Pro 450 已正确接通电源,并处于待机状态

- 注意:Pro 450 服务端会在设备上电后自动启动,无需手动操作

网络配置

- MyCobot Pro 450 默认 IP 地址:

192.168.0.232 - 默认端口号:

4500 - 注意:PC 端需要将本机网卡 IP 设置为 同一网段(例如

192.168.0.xxx,xxx为 2~254 之间的任意数,且不能与机械臂冲突)。 - 具体配置方式请查看 静态IP配置 章节内容。

示例:

- 机械臂 IP:

192.168.0.232 - PC IP:

192.168.0.100 - 子网掩码:

255.255.255.0 - DNS服务器:

114.114.114.114

- 机械臂 IP:

验证:完成网络配置后,可在 PC 终端执行以下命令,若能成功返回数据包,则说明网络连接正常:

ping 192.168.0.232

- MyCobot Pro 450 默认 IP 地址:

- ROS环境搭建

- 使用案例之前,需确保已完成 ROS环境搭建以及ROS代码更新

1 滑块控制

打开命令行并运行:

roslaunch mycobot_pro_450 slider_control.launch

# 如果末端配有myGripper F100 力控夹爪,则运行:

roslaunch mycobot_pro_450 slider_control_force_gripper.launch

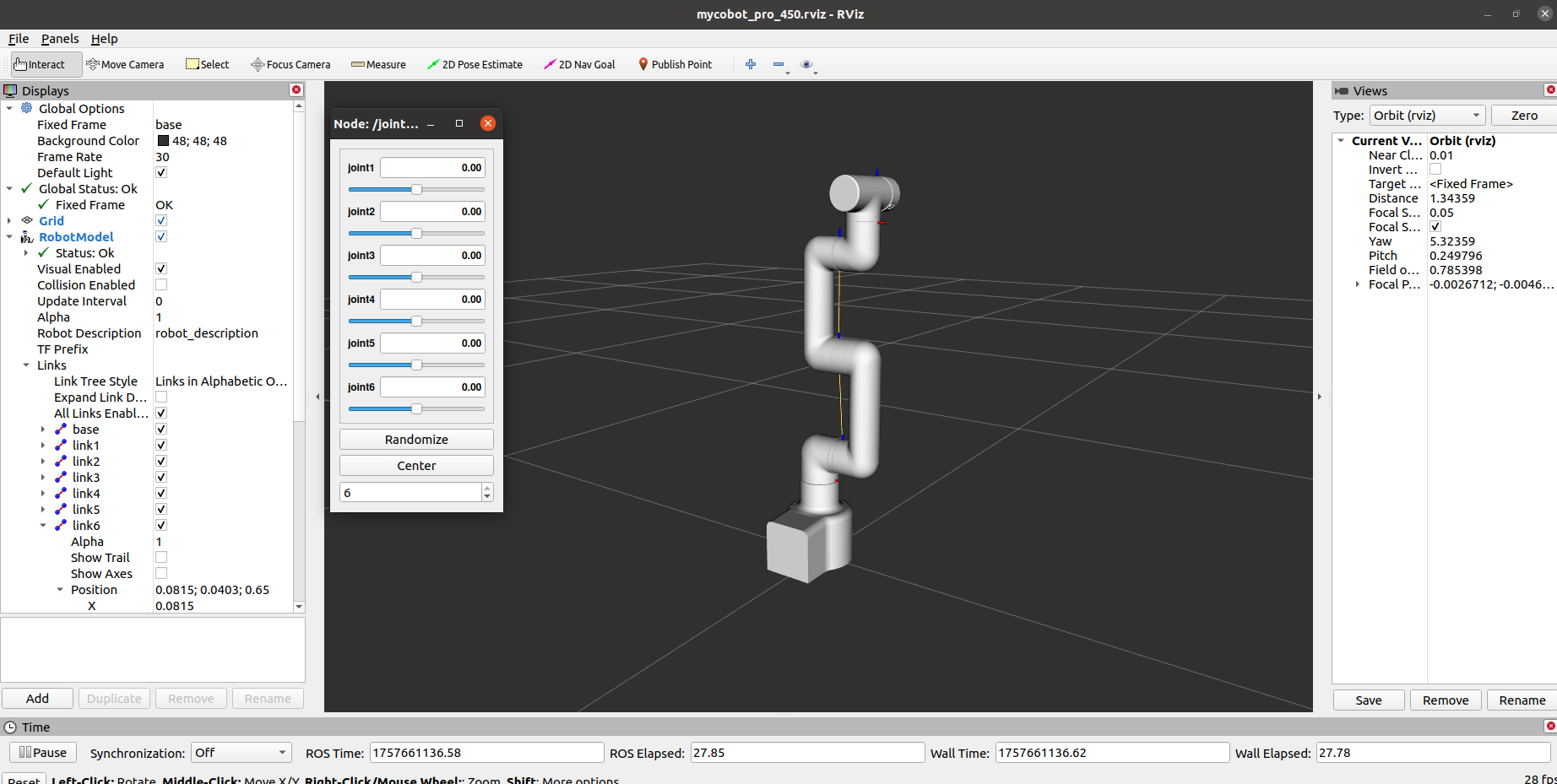

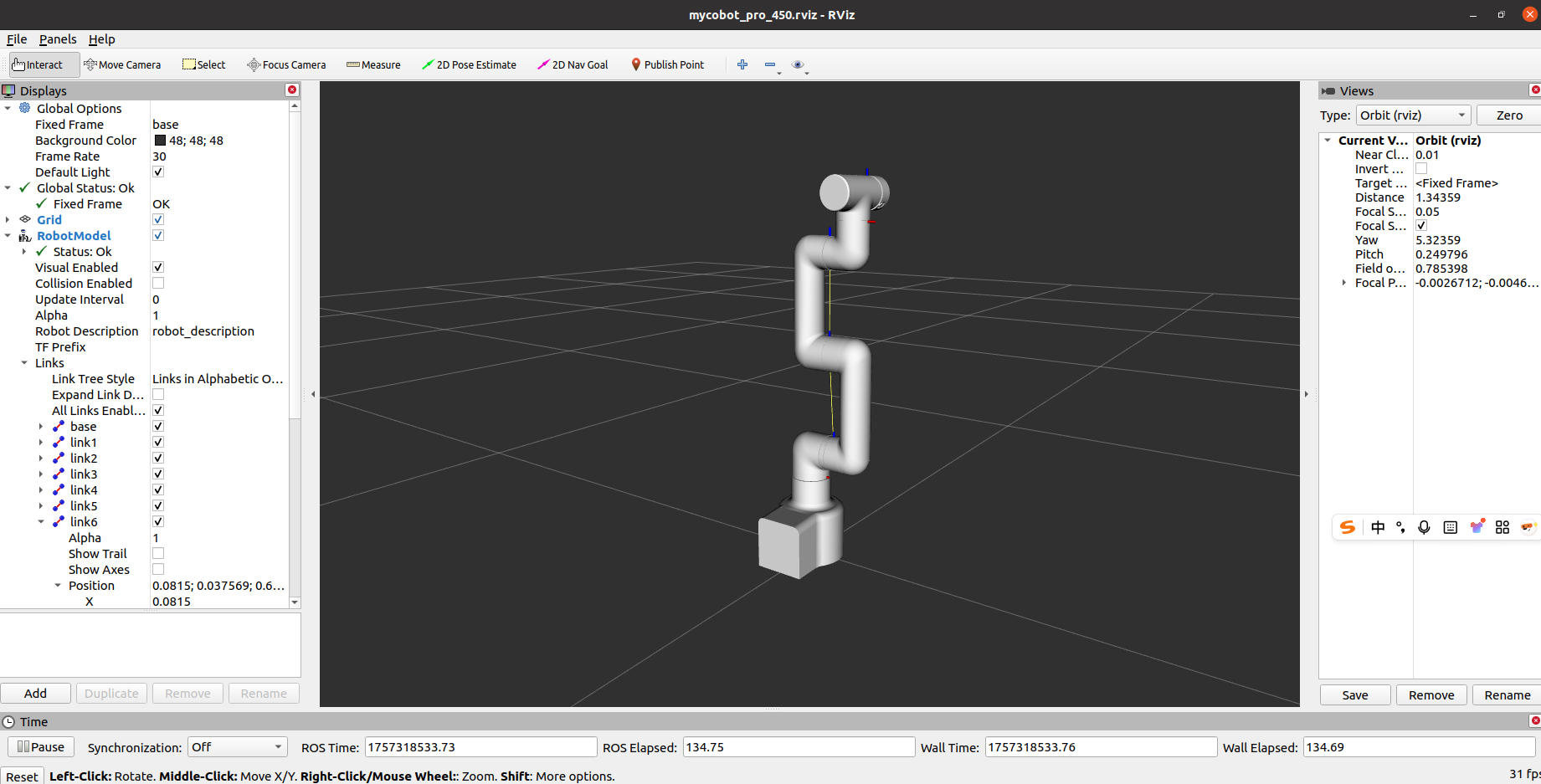

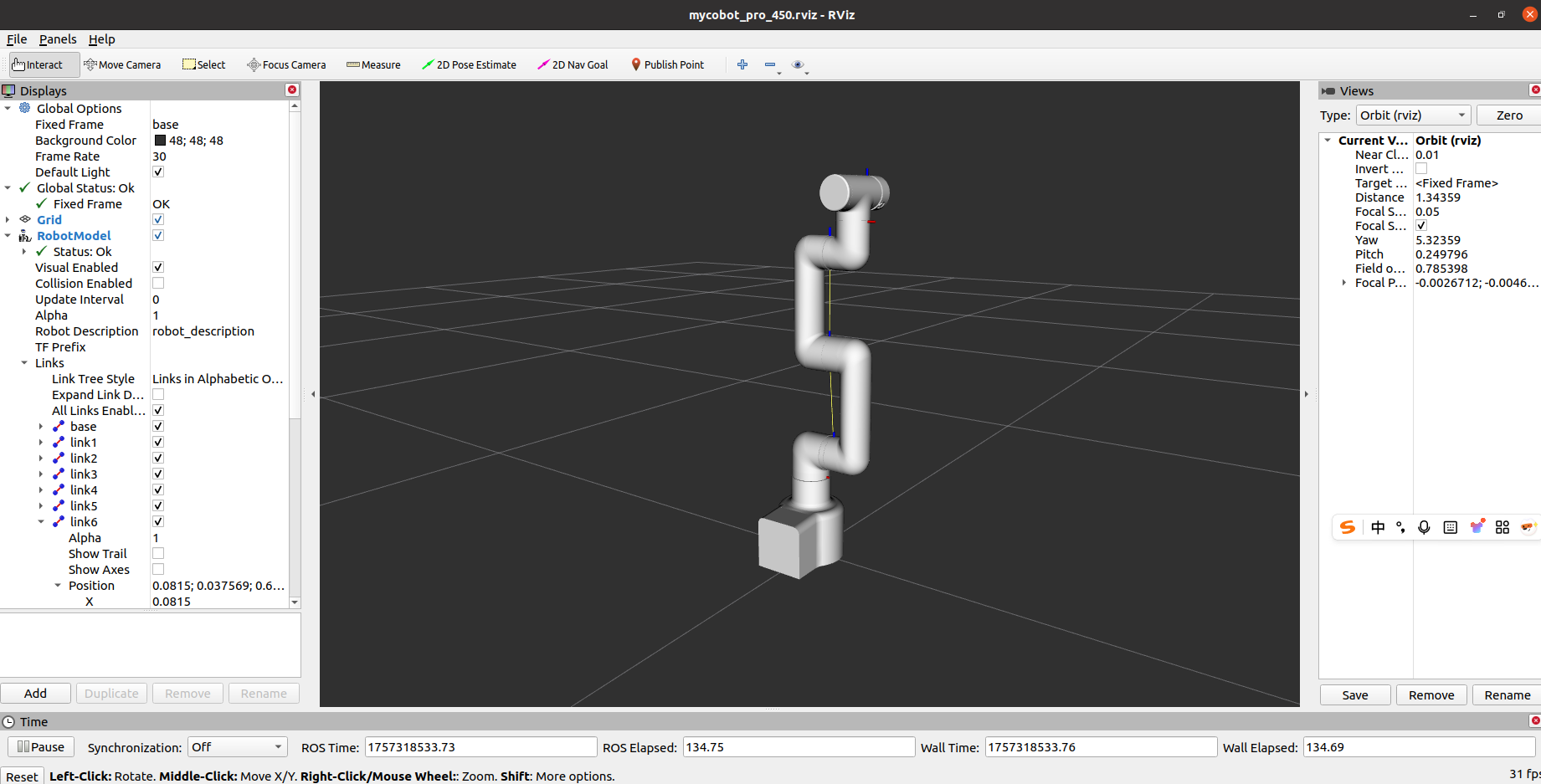

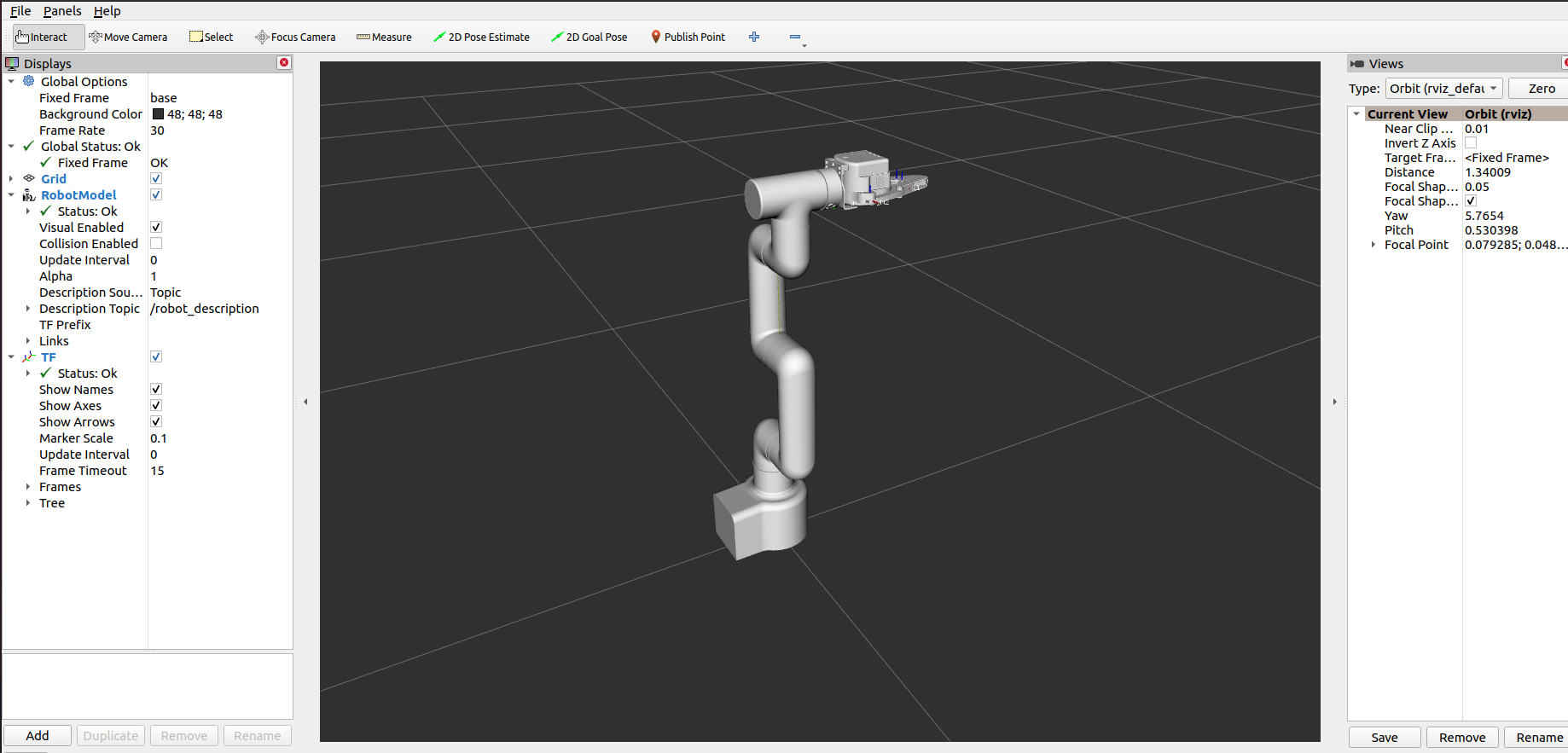

打开 rviz 和一个滑块组件,您将看到如下界面:

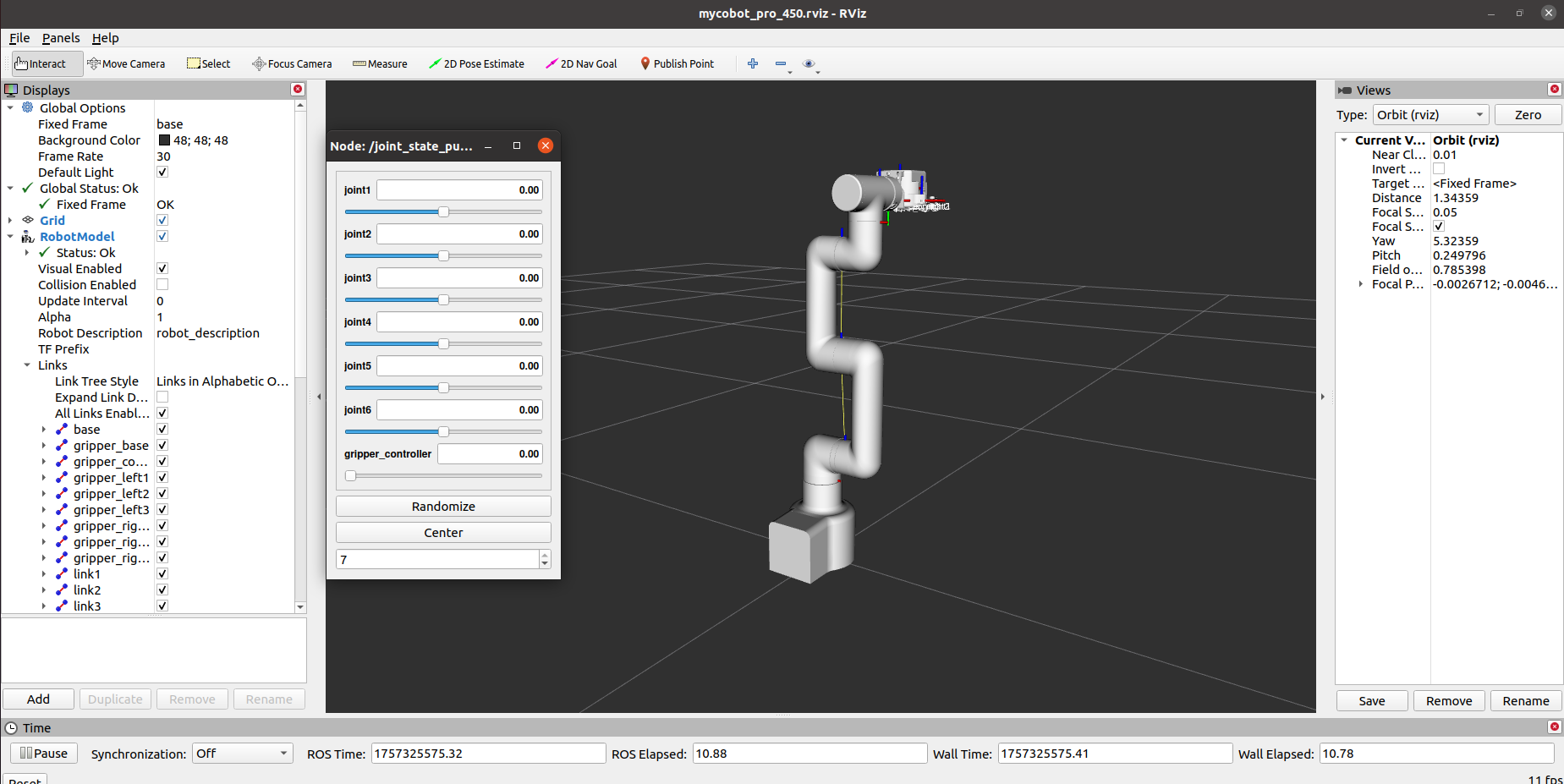

如果末端装有myGripper F100 力控夹爪,则会看到以下界面:

然后你就可以在 rviz 中 控制模型,通过拖动滑块使其移动。如果想让真实的霉菌机器人随着模型移动,则需要打开另一个命令行并运行:

# Pro450 默认ip地址为"192.168.0.232",端口号为 4500。

rosrun mycobot_pro_450 slider_control.py

# 如果末端配有myGripper F100 力控夹爪,则运行:

rosrun mycobot_pro_450 slider_control_force_gripper.py

请注意:由于在命令输入的同时机械臂会移动到模型目前的位置,在您使用命令之前请确保 rviz 中的模型没有出现穿模现象

不要在连接机械臂后做出快速拖动滑块的行为,防止机械臂损坏

2 模型跟随

除了上述控制外,我们还可以让模型跟随真实的机械臂移动。

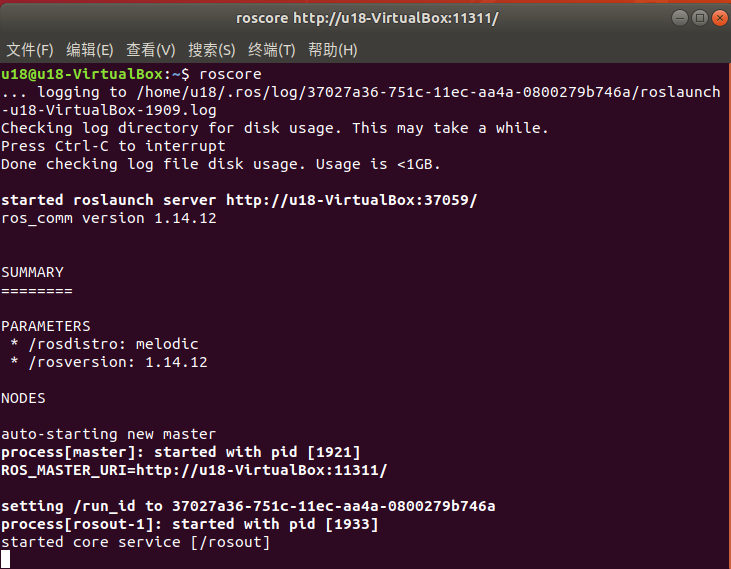

打开命令行,启动ros节点:

roscore

然后打开新的命令行并运行:

rosrun mycobot_pro_450 follow_display.py

运行成功后,需要同时按住机器末端按钮才能拖拽关节移动,终端输出信息如下

Trying to connect to real MyCobot Pro450...

IP: 192.168.0.232, port: 4500

Please press the button at the end of the machine to drag the joint.

请按下机器末端按钮进行关节拖拽运动

Publishing ...

最后打开另一个命令行并运行:

roslaunch mycobot_pro_450 follow_display.launch

它将 打开 rviz,显示模型跟随效果。此时拖动真实机械臂关节,仿真模型将会跟随真实机械臂运动。

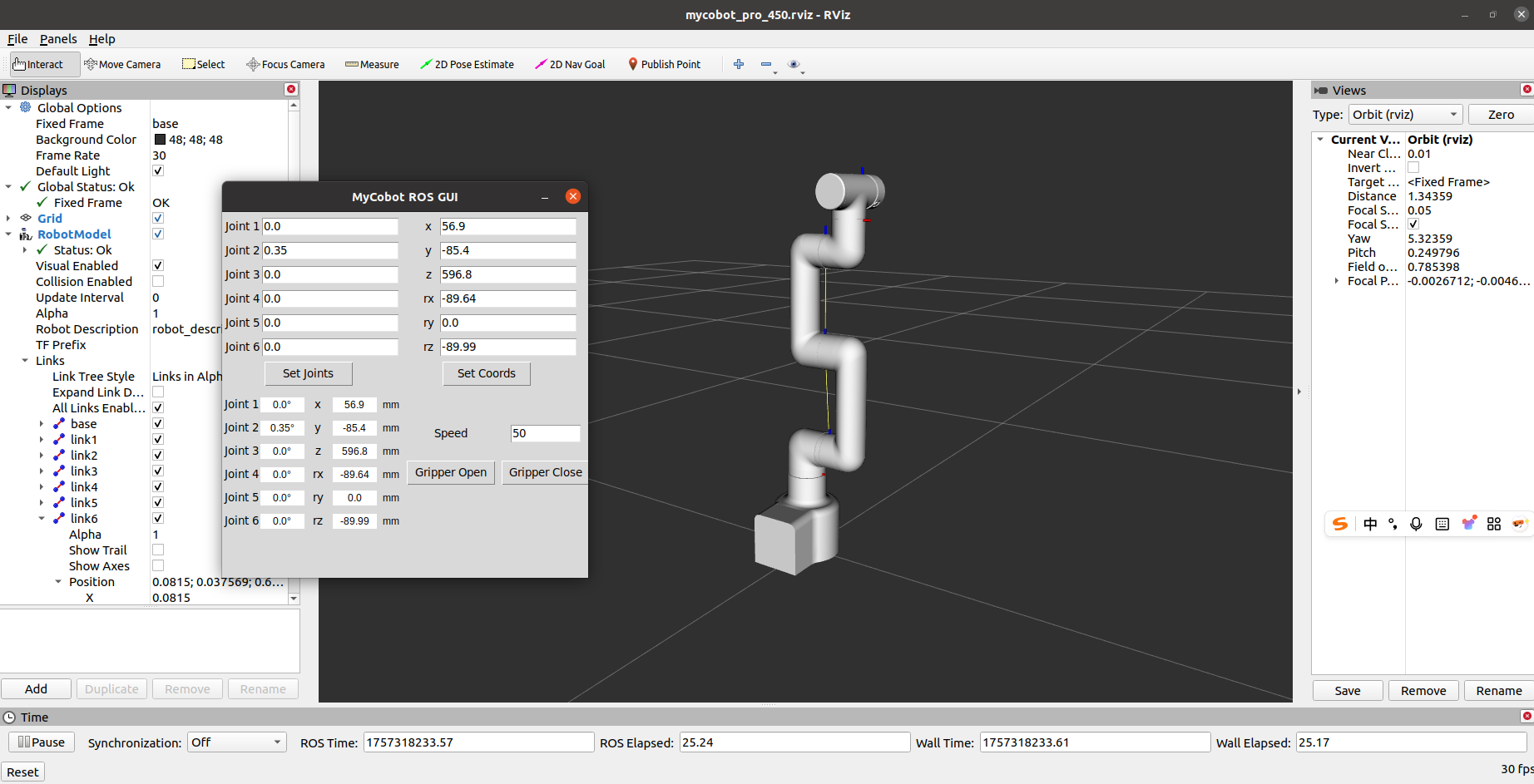

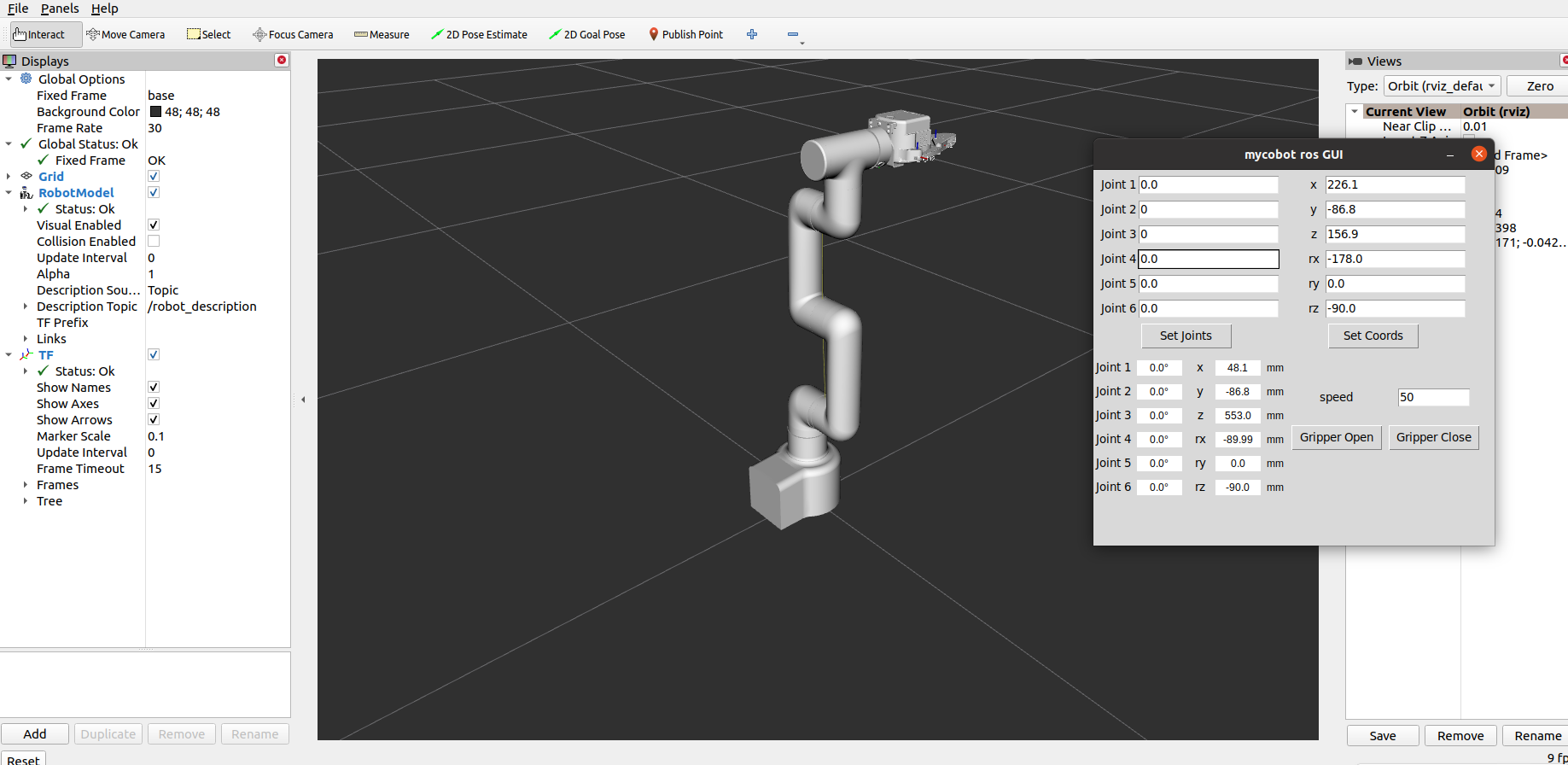

3 GUI 控制

在前述内容的基础上,本软件包还提供了一个简单的图形用户界面(GUI)控制界面。连接到 mycobot。

打开命令行:

# Pro450 默认ip地址为"192.168.0.232",端口号为 4500。

roslaunch mycobot_pro_450 simple_gui.launch

# 如果末端配有myGripper F100 力控夹爪,则运行:

roslaunch mycobot_pro_450 simple_gui_force_gripper.launch

如果末端装有myGripper F100 力控夹爪,则会看到以下界面:

运行成功后,终端信息输出如下:

SUMMARY

========

PARAMETERS

* /mycobot_services/ip: 192.168.0.232

* /mycobot_services/port: 4500

* /robot_description: <?xml version="1....

* /rosdistro: noetic

* /rosversion: 1.16.0

NODES

/

mycobot_services (mycobot_pro450_communication/mycobot_services.py)

real_listener (mycobot_pro_450/listen_real.py)

robot_state_publisher (robot_state_publisher/robot_state_publisher)

rviz (rviz/rviz)

simple_gui (mycobot_pro_450/simple_gui.py)

auto-starting new master

process[master]: started with pid [69286]

ROS_MASTER_URI=http://localhost:11311

setting /run_id to 5d888b36-8c89-11f0-b9c8-1f4f9291f209

process[rosout-1]: started with pid [69301]

started core service [/rosout]

process[robot_state_publisher-2]: started with pid [69304]

process[rviz-3]: started with pid [69308]

process[mycobot_services-4]: started with pid [69310]

process[real_listener-5]: started with pid [69311]

process[simple_gui-6]: started with pid [69317]

Current pymycobot library version: 4.0.1b0

pymycobot library version meets the requirements!

[INFO] [1757318207.730721]: Starting MyCobot service node...

[INFO] [1757318207.733988]: 192.168.0.232,4500

MyCobot Status

--------------------------------

Joint Limit:

joint 1: -162 ~ +162

joint 2: -125 ~ +125

joint 3: -154 ~ +154

joint 4: -162 ~ +162

joint 5: -162 ~ +162

joint 6: -165 ~ +165

[INFO] [1757318207.795377]: Services are ready

然后在GUI界面输入相关角度和坐标信息,点击对应按钮,即可实现真实机器与仿真模型的同步运动

注意: 使用夹爪开关按钮前,请确保自适应夹爪已连接至机器人手臂末端。

4 键盘控制

在 mycobot_pro_450 软件包中添加了键盘控制功能,并在 rviz 中执行实时同步。 该功能依赖于 pythonApi,因此请务必与真正的机械臂连接。

打开命令行并运行:

# Pro450 默认ip地址为"192.168.0.232",端口号为 4500。

roslaunch mycobot_pro_450 teleop_keyboard.launch

# 如果末端配有myGripper F100 力控夹爪,则运行:

roslaunch mycobot_pro_450 teleop_keyboard_force_gripper.launch

运行效果如下

如果末端装有myGripper F100 力控夹爪,则会看到以下界面:

mycobot 的信息将在命令行中输出如下:

SUMMARY

========

PARAMETERS

* /mycobot_services/ip: 192.168.0.232

* /mycobot_services/port: 4500

* /robot_description: <?xml version="1....

* /rosdistro: noetic

* /rosversion: 1.16.0

NODES

/

mycobot_services (mycobot_pro450_communication/mycobot_topics.py)

real_listener (mycobot_pro_450/listen_real_of_topic.py)

robot_state_publisher (robot_state_publisher/robot_state_publisher)

rviz (rviz/rviz)

auto-starting new master

process[master]: started with pid [76496]

ROS_MASTER_URI=http://localhost:11311

setting /run_id to cf3d03b0-8c89-11f0-b9c8-1f4f9291f209

process[rosout-1]: started with pid [76511]

started core service [/rosout]

process[robot_state_publisher-2]: started with pid [76514]

process[rviz-3]: started with pid [76518]

process[mycobot_services-4]: started with pid [76520]

process[real_listener-5]: started with pid [76522]

Current pymycobot library version: 4.0.1b0

pymycobot library version meets the requirements!

[INFO] [1757318398.354867]: 192.168.0.232,4500

MyCobot Status

--------------------------------

Joint Limit:

joint 1: -162 ~ +162

joint 2: -125 ~ +125

joint 3: -154 ~ +154

joint 4: -162 ~ +162

joint 5: -162 ~ +162

joint 6: -165 ~ +165

然后打开另一个命令行运行:

rosrun mycobot_pro_450 teleop_keyboard.py

# 如果末端配有myGripper F100 力控夹爪,则运行:

rosrun mycobot_pro_450 teleop_keyboard_force_gripper.py

你将看到命令行输出如下:

Mycobot Pro450 Teleop Keyboard Controller (ROS1 - Topic Version)

---------------------------------------------------------

Movement (Cartesian):

w (x+)

a (y+) s (x-) d (y-)

z (z-) x (z+)

Rotation (Euler angles):

u (rx+) i (ry+) o (rz+)

j (rx-) k (ry-) l (rz-)

Movement Step:

+ : Increase movement step size

- : Decrease movement step size

Gripper:

g - open h - close

Other:

1 - Go to init pose

2 - Go to home pose

3 - Save current pose as home

q - Quit

currently: speed: 50 change percent: 5

在该终端中,您可以控制机械臂的状态,并使用命令行中的按键移动机械臂。

注意:先输入2机械臂回到起始点之后,再进行其他坐标控制操作,终端会有如下提示:

[WARN] [1758001794.385321]: Coordinate control disabled. Please press '2' first.

[INFO] [1758001804.552778]: Home pose reached. Coordinate control enabled.

[INFO] [1758001817.069637]: Home pose reached. Coordinate control enabled.

[WARN] [1758001836.301070]: Returned to zero. Press '2' to enable coordinate control.

[WARN] [1758001848.830702]: Coordinate control disabled. Please press '2' first.

[INFO] [1758001863.383565]: Home pose reached. Coordinate control enabled.

[WARN] [1758001933.596504]: Returned to zero. Press '2' to enable coordinate control.

[WARN] [1758001942.051899]: Coordinate control disabled. Please press '2' first.

本脚本支持的参数:

- _speed:机械臂的运动速度

- _change_percent:移动距离百分比

5 moveit 使用

mycobot_ros 整合了 MoveIt 部分。

打开命令行并运行:

roslaunch mycobot_pro450_moveit demo.launch

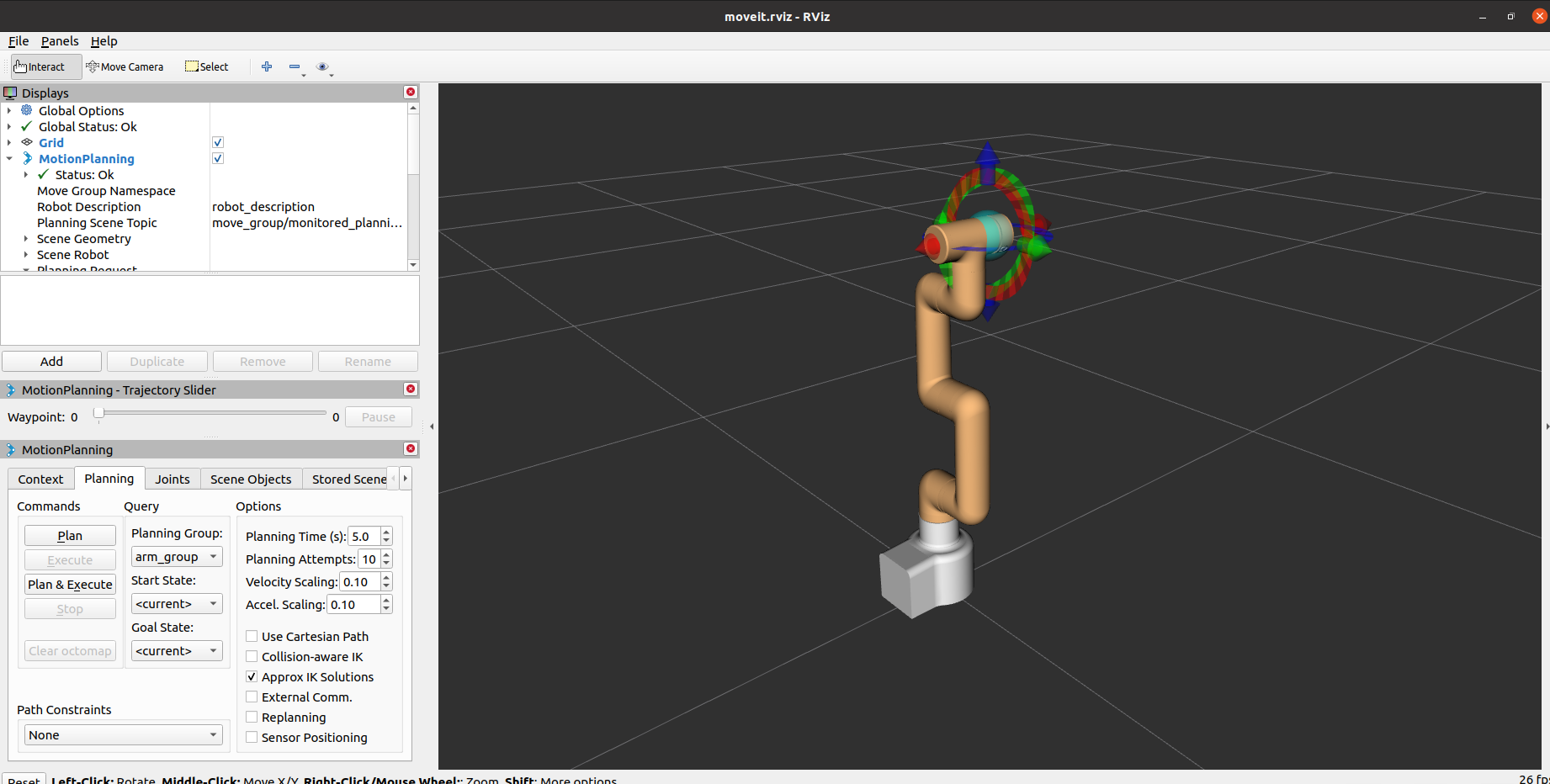

运行效果如下:

终端将输出如下信息,代表成功启动moveit:

[ INFO] [1757321505.678763337]: Loading robot model 'firefighter'...

[ INFO] [1757321505.782983258]: Set joints of group 'arm_group' to pose 'init_pose'.

[ INFO] [1757321505.783324504]: Fake controller 'fake_arm_group_controller' with joints [ joint1 joint2 joint3 joint4 joint5 joint6 ]

[ INFO] [1757321505.783798265]: Returned 1 controllers in list

[ INFO] [1757321505.792047465]: Trajectory execution is managing controllers

[ INFO] [1757321505.792117958]: MoveGroup debug mode is ON

Loading 'move_group/ApplyPlanningSceneService'...

Loading 'move_group/ClearOctomapService'...

Loading 'move_group/MoveGroupCartesianPathService'...

Loading 'move_group/MoveGroupExecuteTrajectoryAction'...

Loading 'move_group/MoveGroupGetPlanningSceneService'...

Loading 'move_group/MoveGroupKinematicsService'...

Loading 'move_group/MoveGroupMoveAction'...

Loading 'move_group/MoveGroupPickPlaceAction'...

Loading 'move_group/MoveGroupPlanService'...

Loading 'move_group/MoveGroupQueryPlannersService'...

Loading 'move_group/MoveGroupStateValidationService'...

Loading 'pilz_industrial_motion_planner/MoveGroupSequenceAction'...

[ INFO] [1757321505.848190702]: initialize move group sequence action

[ INFO] [1757321505.853932419]: Reading limits from namespace /robot_description_planning

Loading 'pilz_industrial_motion_planner/MoveGroupSequenceService'...

[ INFO] [1757321505.867558584]: Reading limits from namespace /robot_description_planning

[ INFO] [1757321505.884930897]:

********************************************************

* MoveGroup using:

* - ApplyPlanningSceneService

* - ClearOctomapService

* - CartesianPathService

* - ExecuteTrajectoryAction

* - GetPlanningSceneService

* - KinematicsService

* - MoveAction

* - PickPlaceAction

* - MotionPlanService

* - QueryPlannersService

* - StateValidationService

* - SequenceAction

* - SequenceService

********************************************************

[ INFO] [1757321505.885485766]: MoveGroup context using planning plugin ompl_interface/OMPLPlanner

[ INFO] [1757321505.885536833]: MoveGroup context initialization complete

You can start planning now!

[ INFO] [1757321508.935642298]: Loading robot model 'firefighter'...

[ INFO] [1757321509.253483659]: Starting planning scene monitor

[ INFO] [1757321509.257223628]: Listening to '/move_group/monitored_planning_scene'

[ INFO] [1757321509.375270577]: Constructing new MoveGroup connection for group 'arm_group' in namespace ''

[ INFO] [1757321510.628737935]: Ready to take commands for planning group arm_group.

基本路径规划操作如下:

如果想让真正的机械臂同步执行计划,则需要打开另一个命令行并运行:

# Pro450 默认ip地址为"192.168.0.232",端口号为 4500。

rosrun mycobot_pro450_moveit sync_plan.py

修改运动速度

为了防止关节在实际机械臂运动过程中晃动,需要降低关节的运动速度。

- 在

sync_plan.py文件中,修改机械臂 Python API 的速度参数,此处改为 25。

...

def callback(data: JointState):

"""Callback function for ROS JointState subscription.

This function converts incoming joint positions (radians) to angles

in degrees and sends them to the Pro450 robotic arm.

Args:

data (JointState): Joint state message containing joint positions.

"""

data_list = []

for index, value in enumerate(data.position):

radians_to_angles = round(math.degrees(value), 2)

data_list.append(radians_to_angles)

rospy.loginfo(data_list)

mc.send_angles(data_list, 25)

...

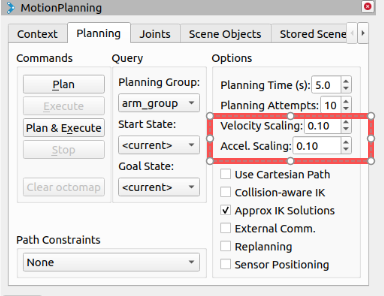

在 Moveit RViz 界面中,修改速度和加速度的缩放比例。在这里,将其改为 0.1,然后保存当前配置。