Background Knowledge

To understand my Cobot, you need to have a deep understanding of the hardware, software, and robot algorithms. Before that, we can understand the progress of robots by understanding their history.

Manufacturing history: from manual to robot

Author: Elephant Rrobotics

In 2019, the global manufacturing industry encountered a major crisis.

The US manufacturing index PMI hit a new low in nearly 10 years, and China's manufacturing index also slowed sharply. China US trade, which has been booming for 30 years, has been hit hard by the trade war.

Since the beginning of industrial civilization in the middle of the 18th century, the history of the rise and fall of world powers and the history of the struggle of the Chinese nation have repeatedly proved that "manufacturers win the world".

Trump successfully ran for president under the banner of "revitalizing the American manufacturing industry", although it has never been practiced; Recently, the documentary "American Factory", which is based on Fuyao Glass, a Chinese enterprise, supervised by former US President Barack Obama, has become increasingly noisy, and the target is the manufacturing industry. Some people say that this is a continuation of the American dream that Obama did not realize when he was president: “he talked about what he did not finish when he was a politician”.

It is an indisputable fact that the manufacturing industry has fled the United States and turned to China. Fuyao in the film runs in the opposite direction. Insisting on building a factory in the United States is only a last resort to take care of the local automobile industry in the United States, which does not contribute much to the current trend of manufacturing.

Since the Industrial Revolution, the global manufacturing industry has experienced four major migrations. The focus of the manufacturing industry has shifted from Britain and Europe to the United States, Japan and China. At present, the fifth migration of global manufacturing industry is in progress, and a new round of manufacturing centers has begun to flow to Vietnam, Indonesia, India and other countries in Southeast Asia.

The socialist economic road with Chinese characteristics also cannot escape the development law of manufacturing industry. With the disappearance of China's demographic dividend, the path of traditional manufacturing industry relying on human development is becoming narrower and narrower. At the same time, intelligent equipment represented by industrial robots is bringing revolutionary industrial changes to the production methods of traditional equipment manufacturing, logistics and other related industries.

Such a change may only be a small segment in the long history of manufacturing. But for the country, every reform and innovation is a huge change under the torrent.

At the beginning of the film 2001: A Space Odyssey, a prehistoric ape man learned to kill other animals with bones as weapons because of the influence of the black stone tablet. At the end of the film, he threw the bone into the sky. The picture turned and a spaceship was born.

From the stone tools of ancient times to the spaceships that are still being explored, the changes and developments that span 2.6 million years of history flow through the entire history of human civilization manufacturing.

The world we live in now, where our eyes are, is all made by human beings; But this is only a relatively broad manufacturing. The real manufacturing industry is an industry in which manufacturing resources (materials, energy, equipment, tools, capital, technology, information and manpower) are transformed into large-scale tools, industrial products and living consumer products that can be used and utilized by people through the manufacturing process according to market requirements in the era of mechanical industry.

01. The grope before dawn

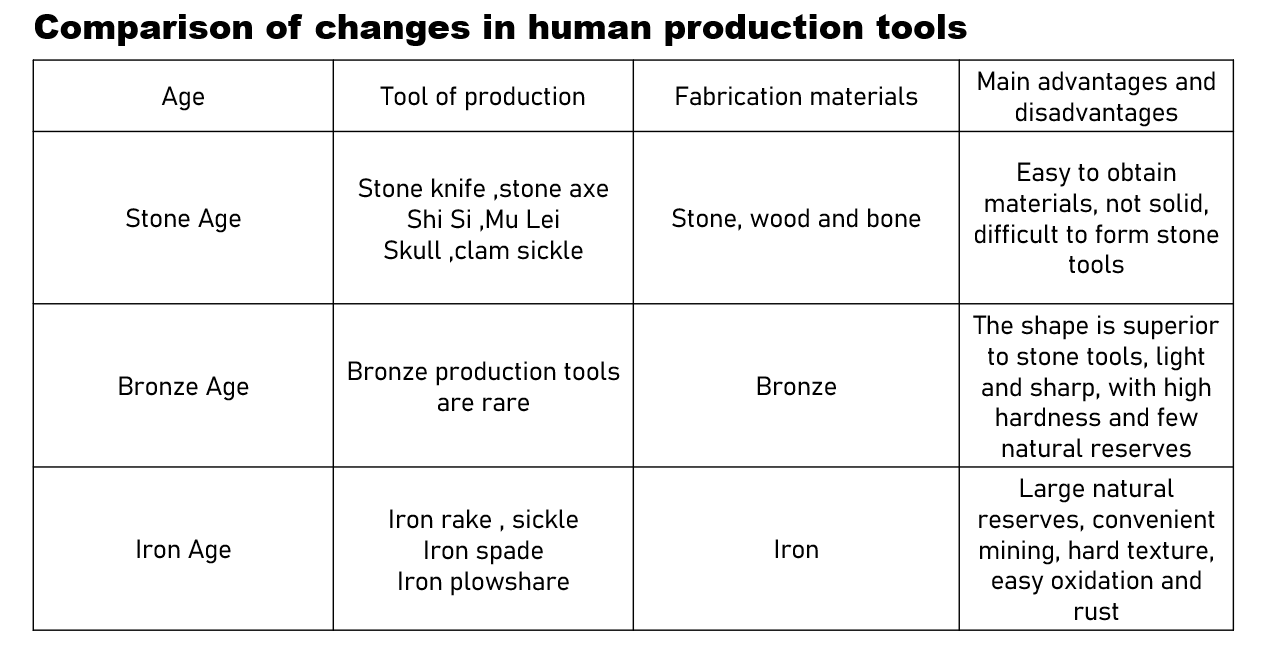

In ancient times, the world's main economy was still dominated by nomadic civilization and agricultural civilization, the embryo of manufacturing was still in the process of breeding, and early manufacturing was developed in the form of updating manufacturing tools.

So far, the earliest stone tools found were excavated in Kenya, which has a history of about 2.6 million years. The most primitive tools appeared in the Paleolithic Age, with different shapes and sizes, mainly in the form of blocks, slices and blades.

Also in Kenya, in 1981, according to the excavation evidence, the history of human control of fire sources can be traced back to 1.42 million years ago.

The use of tools and energy is considered to be one of the main factors that distinguish human beings from other species. On this basis, all kinds of human ingenuity burst out, and the civilized life belonging to mankind began.

After human settlement, the pace of scientific and technological development has been greatly accelerated, and the emergence of metal has become a major leap in the development of human scientific and technological civilization.

The real mastery of casting technology by human beings comes from the investment casting technology invented by the ancient Egyptians. This technology is formed by injecting molten metal into the model and discharging molten beeswax. Later, the ancient Egyptians also invented the metal saw, which was used to quickly saw wood materials.

The Chinese believe that the saw was invented by Lu Ban in the 5th century BC. But the Chinese did invent the blast furnace in 400 BC to refine bronze. The ironmaking industry evolved from it, which produced millions of weapons and clothing, and became an indispensable tool for Qin Shihuang to unify China.

The innovation of manufacturing tools benefits from the continuous development and innovation of manufacturing materials and technology. But the way to improve manufacturing efficiency is not only to improve the process and materials.

More than 600 years before the beginning of the Industrial Revolution, the Venetians pioneered the large-scale production model - through specialized division of labor, the labor force engaged in different types of work was dispersed in a production line. The birth of the production line has greatly improved the productivity and output, and realized the large-scale production of high-quality weapons.

This also means that manufacturing is no longer limited to manufacturing materials and technology, but also includes manufacturing systems. At the same time, the manufacturing conditions are basically formed.

However, in the thousands of years before the Industrial Revolution, in the context of people's inability to increase their use of energy and tools exponentially, modern human beings repeatedly fell into the Malthusian trap: population growth exceeded food supply, which would lead to the reduction of food per capita, and eventually the weak would starve to death.

The endless repetition is like a magic spell that can not escape. The darkness before dawn makes people suffocate until the arrival of the Industrial Revolution.

02. The ingenuity of "Steam Punk"

In order to cook quickly and retain the rich nutrition and soft taste of bones, the pressure cooker was invented by French scientist Benjamin in 1679. The invention of pressure cooker made him find an interesting phenomenon: atmospheric pressure will affect the boiling point, and the power of steam can lift the lid of the cooker.

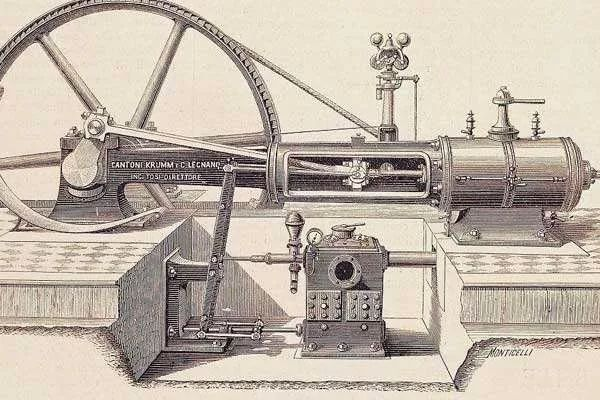

In 1698, Seville took inspiration from Banping's design and invented the water pump - a basic steam engine that can use steam power to alleviate the problem of mine drainage. In 1712, 14 years later, Newcomen solved the distance defect of Seville pump, and the two sides jointly invented the atmospheric steam engine.

Although the gas condensation speed of the atmospheric steam engine is slow, the piston motion of the steam stroke cannot be generated continuously, and the efficiency is low; However, due to the emergence of coke iron smelting technology, the demand for coal has risen sharply, and it is still warmly sought after by people.

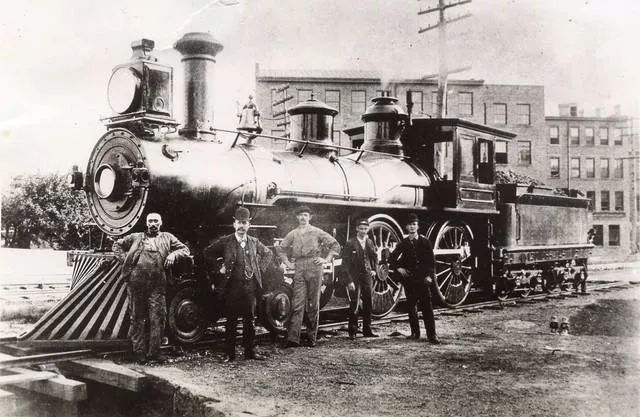

Atmospheric steam engine

At the same time, the appearance of "Jeanne Spinning Machine" first triggered a chain reaction of machine invention and technology innovation in the cotton textile industry, opening the prelude to the industrial revolution.

The turning point of destiny took place in 1785. Watt invented the first steam engine with an independent condenser, which is small in size and high in durability. It can continuously and efficiently generate piston movement to provide rotary kinetic energy. The use of the improved steam engine has greatly promoted the popularization and development of the machine, and the human society has entered the "steam age".

The technological innovation brought about by the industrial revolution has a significant impact on manufacturing in various forms

In industrial production, machine production has gradually replaced manual operation, and a new form of production organization - factory has emerged. The economic society has transformed from agriculture and handicraft industry to the mode of industrial and mechanical manufacturing driving economic development, and the model of manufacturing enterprises has begun to take shape; The enterprise forms a workshop type management mode.

In March 1776, Adam Smith put forward the scientific definition of "division of labor" in his "Wealth of Nations" for the first time, which is to divide manufacturing into several specific tasks and assign them to different people for processing. Because of the great role of labor division in improving labor productivity and enhancing national wealth, the theory of labor division gradually evolved into the main mode of enterprise management.

In addition, in terms of manufacturing system, in 1797, Whitney negotiated and reached a contract to produce 10000 rifles for the U.S. government. Therefore, the concepts of "interchangeable parts" and "matching assembly" were also widely spread in the United States.

Relying on the capital accumulation completed by the industrial revolution, the social structure has also undergone major changes; The emergence of emerging cities and the process of world industrialization have provided a fertile growth environment for the vigorous development of manufacturing.

However, at this time, the manufacturing industry was still in its infancy, because science and technology were only partially invented and created, and had not yet been truly combined in the manufacturing industry, and the concept of the relevant manufacturing system was only a preliminary theory, which had not been tested by practice.

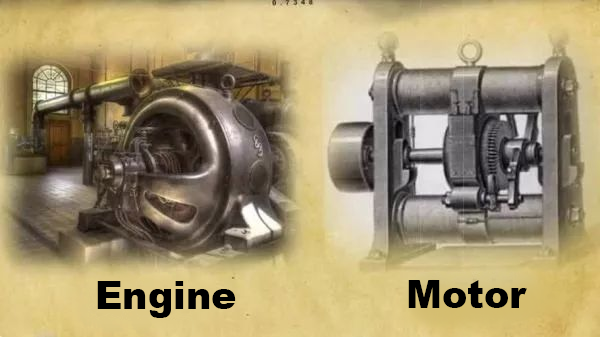

03. “Electric flint” is triggered at any moment

When the manufacturing industry is no longer limited to small family workshops, but has grown into a large-scale production factory, the major changes in advanced production technology and production relations have played a decisive role, and the key lies in the development of technology and innovation.

During the outbreak of the second industrial revolution, the complexity and progressiveness of science and technology reached a new height - natural science was closely integrated with industrial production. New technologies and inventions are far beyond the scope of a country, and the scale is more extensive. People begin to try more large-scale equipment that could not be completed before.

Among them, the extensive application of electricity, the creation of internal combustion engines and new means of transportation, and the invention of new means of communication became the most prominent representatives of science and technology at that time, and the manufacturing industry developed rapidly.

In order to produce automobiles in large quantities, Lansomoz invented an invention that innovated the entire automobile industry - the assembly line. The invention of the assembly line increased the output of automobiles from 425 in 1901 to 2500 in 1902. Until 1913, Ford created the assembly line on the basis of the concept of assembly line. The mode of mass production further improved the automobile production and greatly reduced the production cost.

Taylor's scientific management concept has scientifically and rationally defined each link in manufacturing, including:

- Working task time and rhythm standard of workers;

- Widespread use of industry standards;

- Piece system and labor incentive;

- Data collection in the factory to replace workers and cost accounting。

The emergence of new concepts and models has led to the over detailed division of labor in manufacturing technology and the functional decomposition of manufacturing systems, and gradually formed a management model with scientific management as the core and the implementation of standardization and process, so that the enterprise's people and "work" can be matched.

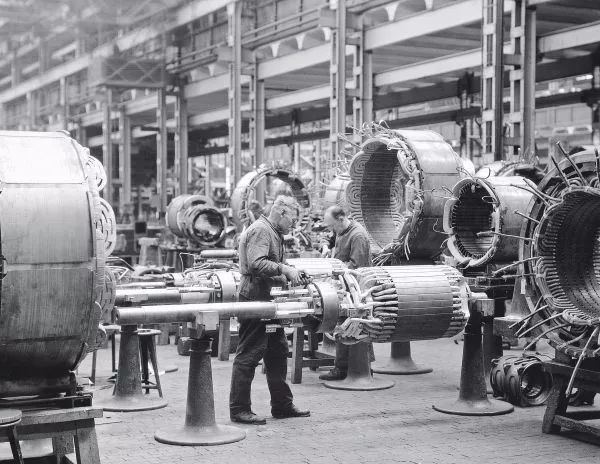

Siemens workshop in Germany

Relying on the capital accumulation completed by the vigorous development of the industrial revolution, countries such as Britain, France, Germany and the United States took the lead in entering the modern industrial powers, forming two major industrial zones in Western Europe and North America. Among them, heavy industry has developed rapidly and gradually occupied the leading position in the economy. However, the economic development of the whole world was extremely uneven at that time.

At the same time, the manufacturing industry began to diverge from labor-intensive industries and technology intensive industries. This has also become the initial model of the four echelon global manufacturing economy.

- First echelon:A global science and technology innovation center led by the United States;

- Second echelon:High end manufacturing field, including EU and Japan;

- Third echelon:Middle and low-end manufacturing, mainly in some emerging countries, including China;

- The Fourth echelon:Resource exporting countries, including OPEC (Organization of Petroleum Exporting Countries), Africa, Latin America, etc.

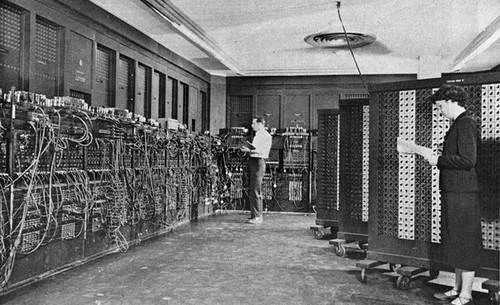

04. Computer:dance of the soul

Technology and innovation have always been the key to the development and transformation of manufacturing industry. The emergence of computers has injected new soul into the manufacturing industry, and the development of the manufacturing industry has made a qualitative leap.

The first digital electronic computer was invented by German engineer Conrad Chuzer in 1941. This is the first computer to be completely programmed.

- In 1963, CAD began to allow users to use a "photoelectric pen" to draw on the system.

- In 1971, Bessel, a French engineer working in Renault, invented the computer aided manufacturing system CAM, which began to establish a virtual connection between the computer end and the mechanical equipment of the factory, and realized control.

- In 1983, Compaq developed the first laptop computer. The all-in-one portable design and the IO design as simple as possible have achieved great success.

The world's first computer

PLC was born in General Motors in 1960. Similar to computers, they are controlled by software to achieve fixed instructions; But PLC programming is simpler and more convenient to use. At this stage, the factory adopts a large number of mechanical equipment controlled by real electronic and information technology automation, such as PC, PLC single-chip microcomputer, for production.

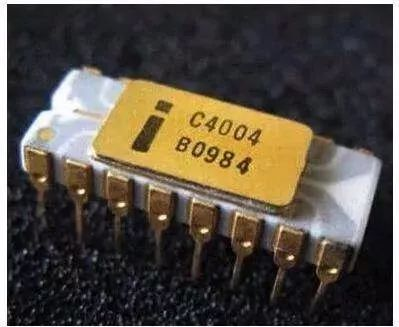

Because of the large size of computers at that time, microcomputers and microcontrollers were invented by Ted Hoff of Intel Corporation in 1971. It was originally designed to centralize calculators with different functions, and then the Intel 4004 microprocessor was invented.

Intel 4004 microprocessor

The development of microprocessors has greatly driven the automation and intelligence of various manufacturing tools. Since then, machines have gradually replaced human operations, taking over not only a considerable proportion of "physical labor", but also some "mental labor".

Manufacturing tools are not only special equipment for process production, but also more general manufacturing tools that replace workers and serve the manufacturing system.

The earliest robot can be traced back to 1495. Leonardo da Vinci created the earliest mechanical knight robot; However, the first modern fully automatic robot was invented by Dr. Walter, an American neuroscientist, in 1948. It is a small robot similar to a turtle. It has external light sensing and tactile sensing, and can move by itself with the help of simple circuits.

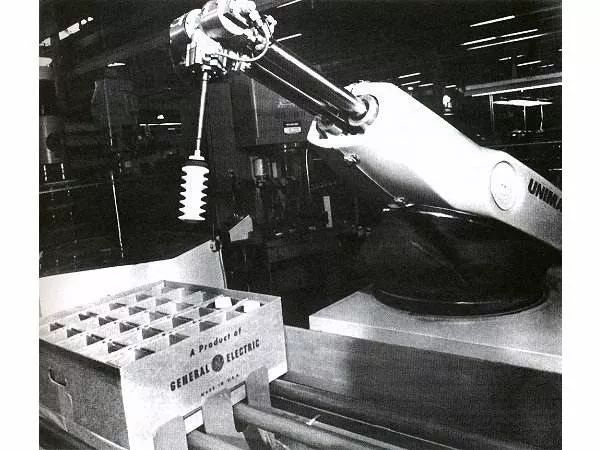

It was not until the 1950s that American engineers George Dewar and Joseph Engelberg put forward the concept of industrial robot, namely industrial manipulator. After several prototype tests, the Unity Company where Ingelberg worked produced the first mechanical arm named Unity, which weighs 2 tons and serves the assembly line of General Motors. At that time, only the transfer of hot pressed castings between different stations was realized, and the welding of the car body began in the following years.

Unimate MachineArm

On the basis of upgrading Industry 2.0, the extensive application of electronic and information technology has further greatly improved the degree of automation control in the manufacturing process, and the production efficiency, yield, division of labor and cooperation, and the service life of mechanical equipment have also been improved unprecedentedly; The form of production organization has changed from a factory to a modern big factory, and mankind has entered an era of overcapacity.

Due to the different resource endowments of various countries, the development of global manufacturing industry has begun to connect, and the manufacturing industry has gradually formed a globalization model with different industrial chain division. However, with the rising cost of means of production in the industrial hegemony, the global manufacturing industry has experienced multiple migrations since the 20th century, and the processing and manufacturing centers have been shifting constantly.

05. In the age of intelligence, the future has come

People often use the most representative production tools to represent a historical period, such as the Stone Age, Bronze Age, Iron Age, Steam Age, Electrical Age, Atomic Age, etc; The most representative production tool in the 21st century is not the Internet.

Based on the emergence of computers, the Internet was born in 1969. At first, it was just to resist the nuclear threat of the former Soviet Union and quickly transmit information and data; In 1973, Xerox developed the Internet in order to connect different computers and computing equipment. Until today, the Internet still plays an important role in the information interconnection of the factory; Of course, it is far more than that.

The Internet protocol (TCP/IP), invented by Robert Kahn and Wendenshev, has opened the last barrier of communication between computers; The greatly expanded capacity and possibility of the Internet will make the interconnection of all things a reality.

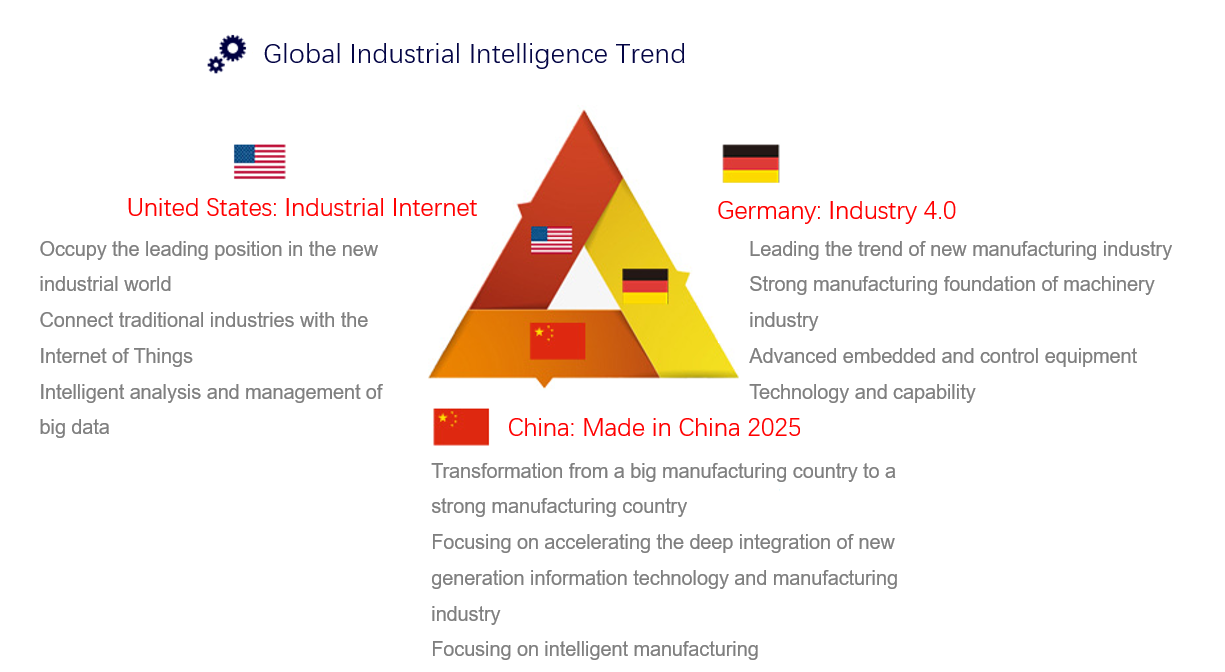

The combination of new technologies such as the Internet, big data, cloud computing, and the Internet of Things with industrial production has enabled mankind to enter an intelligent era. In the intelligent era, the production organization form of the manufacturing industry has changed from a modern large factory to a factory that integrates the virtual and the real. Flexible production and personalized production have become the darling of the times.

With the intellectualization and interconnection of manufacturing, robots have also made great progress.

Before 2010, most industrial robots worked repeatedly according to fixed procedures, which could not take into account the changes in the actual environment. Moreover, the programming was complex and could not be used by ordinary people.

In 1996, the concept of cooperative robot was proposed by J. Edward Colgate and Michael Peshkin, professors of Northwestern University in Lino, that is, robots can perceive changes in the surrounding environment and are easier to use and interact.

In 2008, the Danish company invented the first cooperative robot UR 5, which can realize collision stop, graphical programming and other functions, realizing the popularization of cooperative robots.

GGII data shows that since 2008, the cooperative robot industry has entered a rapid development period from the embryonic stage; As of July 2019, the number of global cooperative robot manufacturers has exceeded 100, including more than 70 cooperative robot manufacturers entering the Chinese market. "Cooperative robot" has gone from concept to popularity, and has gradually become a strategic product that robot manufacturers are competing for.

Thanks to its high flexibility, security and ease of operation, cooperative robots have a wider application extension than traditional industrial robots, which can be applied not only in the industrial field, but also in the commercial service field.

Elephant Robotics

In 2019, Elephant Robot developed the first portable cooperative robot, Catbot; The more portable and easy to use design and the application of examples in dozens of countries in Europe, America and Asia have expanded the possibility of cooperative robots in more fields.

Adam Smith, the founder of classical economics, once said that "the ultimate goal of all production is to meet people's needs". The intelligent era enables people to re understand the world and themselves.

However, the realization of intelligent manufacturing requires the support of technical products at multiple levels, including industrial robots, 3D printing, industrial Internet of Things, cloud computing, industrial big data, knowledge work automation, industrial network security, virtual reality and artificial intelligence. And these technology products will generate countless business opportunities and listed companies.

"In all previous technological revolutions, a person, an enterprise, or even a country can only choose two paths; either join the tide and become the top 2%, or wait and see and be eliminated."

The smart manufacturing station is at the forefront of the global manufacturing development trend, which will bring a new round of competition between production methods, industrial forms and business models. The development of enterprise intelligent manufacturing is still an inevitable requirement and trend.

Dickens once said in A Tale of Two Cities, "This is the best time, but also the worst time.". This statement applies not only to the Second Industrial Revolution, but also to the current era, which is undergoing major changes.

The development of science and technology is unfathomable, and the future development of manufacturing industry is unknown to us. In the current of history, the only thing we can do is to adapt to the development of the times and run our own stick well in this relay race.