Motor & Steering Gear

What is Motor?

- 1 According to the type of working power supply, it can be divided into::DC(Direct Current) motor and AC (Alternating Current) motor

- 1)According to the structure and working principle, DC motors can be divided into:Brushless DC motor and Brushed DC motor。

- Brushed DC motor can be divided into:Permanent magnet DC motor and Electromagnetic DC motor.

- Electromagnetic DC motor can be divided into:Series excited DC motor,Shunt DC Motor ,Separately excited DC motor and Compound DC motor.

- Permanent magnet DC motor can be divided into:Rare earth permanent magnet DC motor,Ferrite permanent magnet DC motor and Al Ni Co permanent magnet DC motor

- 2)Alternating Current Dynamo can be divided into:Single phase motor and Three phase motor

- 1)According to the structure and working principle, DC motors can be divided into:Brushless DC motor and Brushed DC motor。

2 According to use, it can be divided into:Motor for driving and Control motor

- 1)Motor for driving can be divided into:Electric tool(including drilling, polishing, polishing, grooving, cutting, reaming and other tools),Household Electrical Appliances(Including washing machine, electric fan, refrigerator, air conditioner, recorder, video recorder, DVD player, vacuum cleaner, camera, hair dryer, electric shaver, etc),Other general small mechanical equipment(Including various small machine tools, small machinery, medical instruments, electronic instruments, etc)

- 2)Control motor can be divided into:Stepping motor and Servo motor, etc.

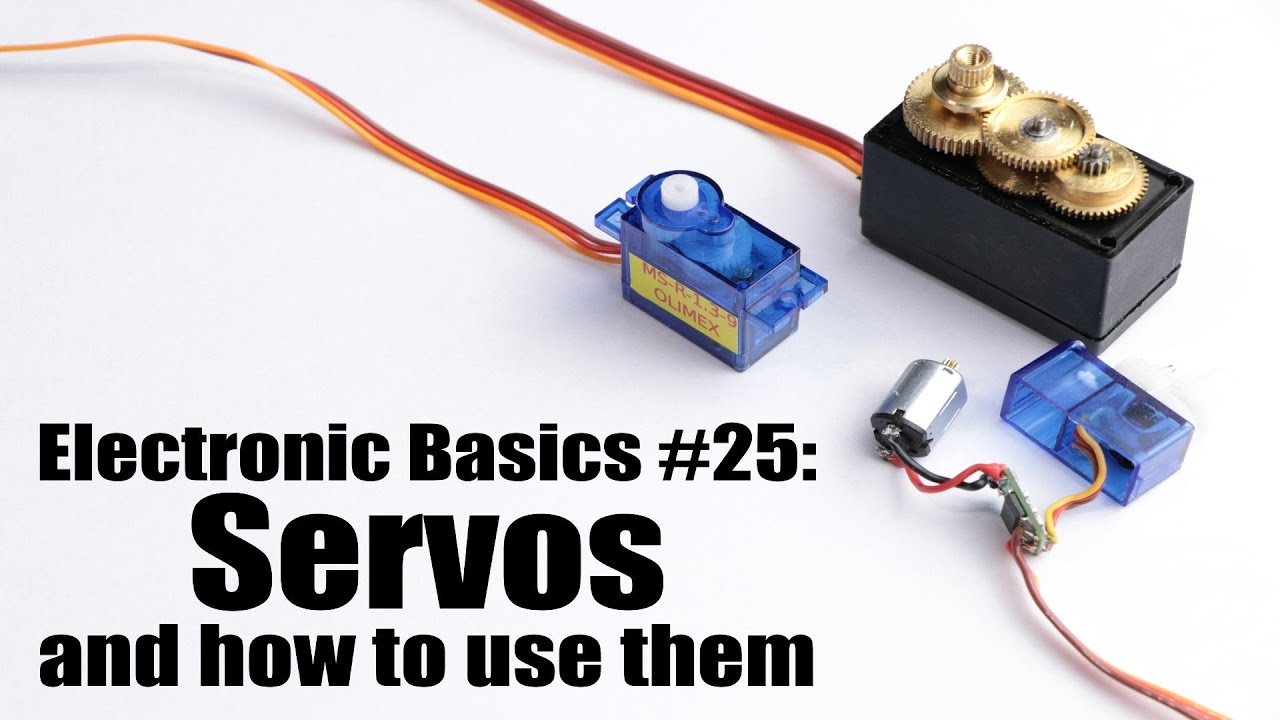

What is Steering gear?

The steering gear is actually a servo motor. Because domestic users have started to use the rudder shaft control of equipment such as aircraft models, these lightweight servo motors are called steering gear in China.

What is Servo Motor

Servo motor refers to the engine that controls the operation of mechanical components in the servo system. It is an indirect speed change device for auxiliary motor.

The servo motor can control the speed and position accurately, and can convert the voltage signal into torque and speed to drive the control object. The rotor speed of the servo motor is controlled by the input signal and can respond quickly. In the automatic control system, it is used as an actuating element, and has the characteristics of small electromechanical time constant, high linearity, etc. It can convert the received electrical signals into angular displacement or angular velocity output on the motor shaft. It is divided into DC and AC servo motors. Its main feature is that when the signal voltage is zero, there is no rotation phenomenon, and the speed decreases at a constant speed with the increase of torque.

Working principle of Servo Motor

- 1.Servo Mechanism is an automatic control system that enables the position, orientation, state and other output controlled variables of an object to follow any change of the input target (or set value). The servo is mainly positioned by pulses. It can be basically understood that when the servo motor receives a pulse, it will rotate the angle corresponding to one pulse to achieve displacement. Because the servo motor itself has the function of sending pulses, so each angle the servo motor rotates will send a corresponding number of pulses, so that a echo, or closed loop, is formed with the pulse received by the servo motor, The system will know how many pulses are sent to the servo motor, and how many pulses are received back at the same time. In this way, it can accurately control the rotation of the motor to achieve accurate positioning, which can reach 0.001 mm. DC servo motor is divided into brush motor and brushless motor. Brushed motor has low cost, simple structure, large starting torque, wide speed range, easy control, and needs maintenance, but it is not convenient to maintain (replace carbon brush), which generates electromagnetic interference and requires the environment. Therefore, it can be used in general industrial and civil occasions sensitive to cost

Brushless motor has small volume, light weight, large output, fast response, high speed, small inertia, smooth rotation and stable torque. The control is complex, easy to realize intellectualization, and the electronic commutation mode is flexible, which can be square wave commutation or sine wave commutation. The motor is maintenance free, with high efficiency, low operating temperature, low electromagnetic radiation and long service life. It can be used in various environments - 2.AC servo motor is also a brushless motor,It is divided into synchronous motor and asynchronous motor. Generally, synchronous motor is used in motion control. Its power range is large and it can achieve great power. Large inertia, low maximum rotational speed, and rapidly decreases with the increase of power. Therefore, it is suitable for the application of low speed and smooth operation.

- 3.The rotor inside the servo motor is a permanent magnet,The UVW three-phase electricity controlled by the driver forms an electromagnetic field, and the rotor rotates under the effect of this magnetic field. At the same time, the encoder feedback signal of the motor itself is sent to the driver, and the driver compares the feedback value with the target value to adjust the rotor rotation angle. The accuracy of the servo motor depends on the accuracy of the encoder (number of lines).

The difference between AC servo motor and brushless DC servo motor in function: AC servo is better because it is controlled by sine wave and has small torque ripple. DC servo is trapezoidal wave. But DC servo is relatively simple and cheap.

</br>

Industrial servo motor

</br>

Industrial servo motor

Characteristic comparison of servo motor

Characteristics of DC Brushless Servo Motor:

Small moment of inertia, low starting voltage and small no-load current; The contact reversing system is abandoned, greatly increasing the motor speed, with the maximum speed up to 100 000 rpm; When the brushless servo motor performs servo control, it can also control the speed, position, torque, etc. without encoder; There is no brush wear. In addition to high speed, it has the characteristics of long service life, low noise, and no electromagnetic interference.

Features of DC Brushed Servo Motor:

- 1.Small size, fast action, fast response, large overload capacity, wide speed range

- 2.Large torque at low speed, small fluctuation and smooth operation

- 3.Low noise and high efficiency

- 4.Advantages such as DC servo formed by feedback (optional) of rear encoder

- 5.Large voltage transformation range and adjustable frequency

Advantages of servo motor for ordinary motor

- 1、Accuracy:Closed loop control of position, speed and torque is realized;The problem of stepping motor out of step is overcome;

- 2、Speed:Good high-speed performance, generally the rated speed can reach 2000~3000 rpm;

- 3、Adaptability:Strong overload resistance, able to withstand the load three times of the rated torque, especially suitable for occasions with transient load fluctuations and requiring fast starting;

- 4、Stable:Stable operation at low speed, no step operation phenomenon similar to that of stepping motor will occur at low speed, and it is suitable for occasions with high speed response requirements;

- 5、Timeliness:The dynamic response time of motor acceleration and deceleration is short, usually within tens of milliseconds;

- 6、Comfort:Significantly reduced heat and noise.

To put it simply, the ordinary motor you usually see will turn for a while and then stop due to its inertia after power failure. The servo motor and stepper motor are quick to stop and go.But Stepper motor has out of step phenomenon.

Application scenario of servo motor

There are too many application fields of servo motor. As long as there is a power source and there is a requirement for accuracy, the servo motor may be involved. Such as machine tools, printing equipment, packaging equipment, textile equipment, laser processing equipment, robots, automatic production lines, and other equipment with relatively high requirements for process accuracy, processing efficiency and working reliability.