Adsorption pump

Adaptive model: myCobot 280 and myPalletizer 260 and mechArm 270

Product Diagram

Adsorption pump: Used for adsorbing objects

Introduction

The adsorption pump, namely a vacuum adsorption pump, has an inlet nozzle and an exhaust nozzle. It is characterized by simple structure, small size, convenient use, low noise, good self-priming ability, etc. It adsorbs objects by controlling the adsorption pump kit as the end effector of the robot arm.

Adsorption pump accessories: power cord x1, DuPont cable x10, one-in-two-out connecting cable x1, and several LEGO parts

Working principle

- When adsorbing an object, the air pump starts air pumping to adsorb the object and stops, and there will be no air leakage for a short time

- When putting down the object, the electronic valve is activated, the exhaust valve is opened, and then air enters the vacuum adsorption pump to release the adsorbed object.

Applicable for

- paper/plastic sheets

- flat and smooth objects,

- cards, etc.

Installation icon (take the M5 version as an example):

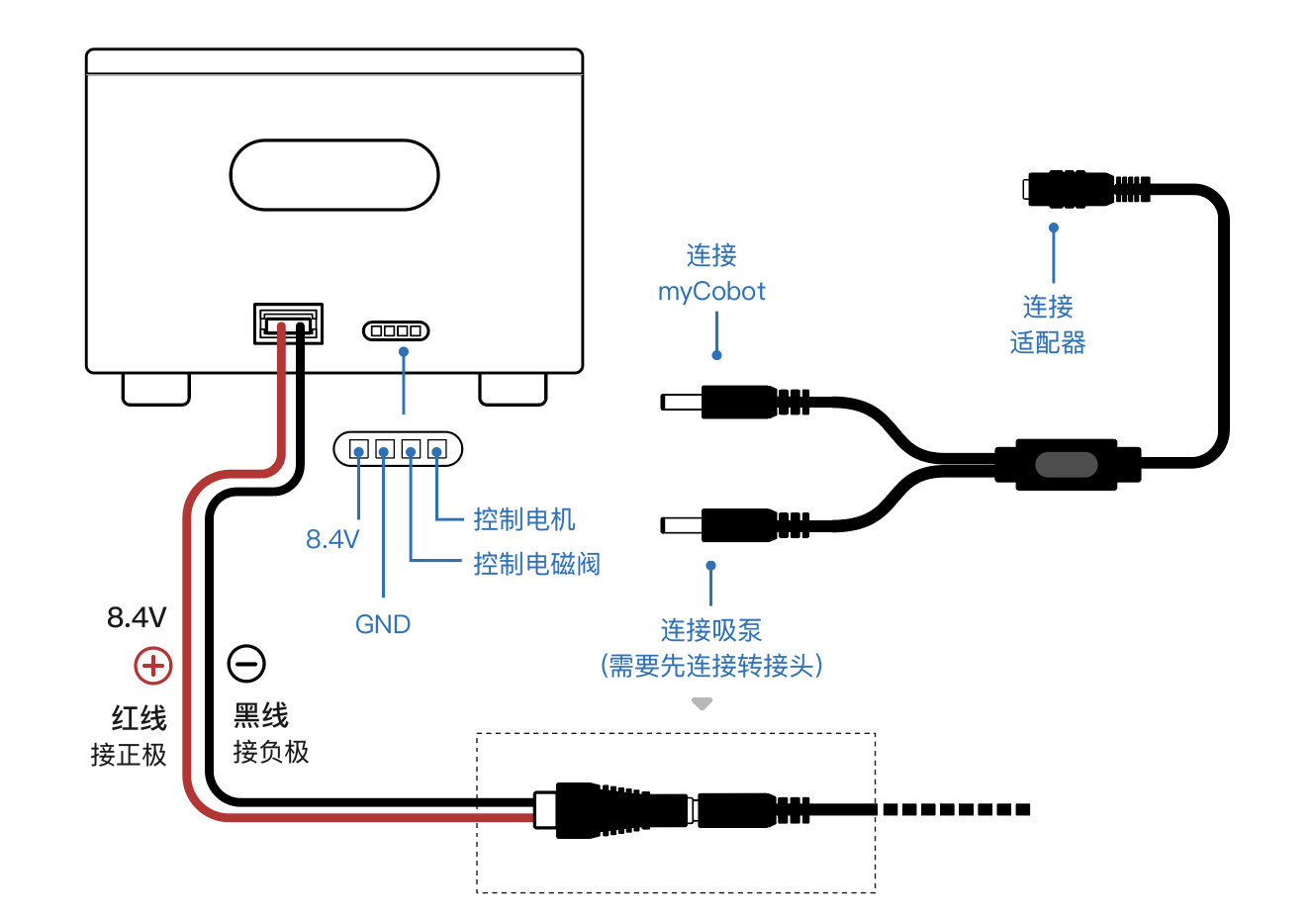

Wiring diagram

Product installation tutorial text

first step: Female cable--The end of the power cable is connected to the port on the left side of the suction pump, the other end is connected to the outlet end of one input and two outlets, the other end is connected to the power port of the robot arm, and the inlet end is connected to the power adapter.

second step: The pin end of the DuPont line is connected (wiring diagram) to the annotated interface for controlling the motor and solenoid valve, and the other end is connected to the G2, G5 pins (M5) 20, 21 pins (Pi) of the robotic arm.

third step: Secure the suction pump head to the end of the robotic arm using LEGO pieces.

Precautions

- Please make sure that the product has been connected successfully according to the instructions

- Please make sure the product is powered by the included adapter

- Please make sure the power adapter is working properly

- Please ensure the connection direction of the positive and negative poles

Use the suction pump in the Python environment:

- 280-M5 version:

from pymycobot.mycobot import MyCobot

from pymycobot import PI_PORT, PI_BAUD # When using the Raspberry Pi version of mycobot, you can refer to these two variables for MyCobot initialization

import time

# Initialize a MyCobot object

mc = MyCobot("COM3", 115200)

# Turn on the suction pump

def pump_on():

# Make 2 work

mc.set_basic_output(2, 0)

# Make 5 work

mc.set_basic_output(5, 0)

# Stop the suction pump

def pump_off():

# Stop 2 from working

mc.set_basic_output(2, 1)

# Stop 5 from working

mc.set_basic_output(5, 1)

pump_off()

time.sleep(3)

pump_on()

time.sleep(3)

pump_off()

time.sleep(3)

- 280-Pi版本:

from pymycobot.mycobot import MyCobot

from pymycobot import PI_PORT, PI_BAUD # When using the Raspberry Pi version of mycobot, you can refer to these two variables for MyCobot initialization

import time

# Initialize a MyCobot object

mc = MyCobot(PI_PORT, PI_BAUD)

# initialization

GPIO.setmode(GPIO.BCM)

GPIO.setup(20, GPIO.OUT)

GPIO.setup(21, GPIO.OUT)

# Turn on the suction pump

def pump_on():

# open suction pump

GPIO.output(20,0)

GPIO.output(21,0)

# Stop the suction pump

def pump_off():

# Turn off the suction pump

GPIO.output(20,1)

GPIO.output(21,1)

pump_off()

time.sleep(3)

pump_on()

time.sleep(3)

pump_off()

time.sleep(3)

For more case references and running results videos, please check 7.7_Use Cases