myAGV

1 Product Introduction

myAGV is the first mobile robot of Elephant. It adopts competition-grade Mecanum wheels and fully wraps the metal frame. The ROS development platform has two built-in slam algorithms to meet the learning of mapping and navigation directions. It provides rich expansion interfaces and can be equipped with my series. The robotic arm realizes mobile grabbing and completes more applications.

2 Product Performance

Omnidirectional movement

- Competition-level Mecanum wheels, Fully Wrapped Metal Frame, Removable Split Structure.

SLAM Lidar

- The built-in gmapping and cartographer algorithms for ROS.Real-time mapping and scanning of Lidar, automatic path planning for obstacle avoidance and navigation.

Built-in camera

- 5 million high-definition camera for object recognition and precise positioning.

Additional extensions

- Double-sided magazines on the body: increased batteries lengthen the working time; Can equip with the suction pump, and cooperate with the robotic arm to achieve more applications.

cargo robot

- Can carry and transport different sizes of cargo boxes arbitrarily, release your hands.

compound robot

- It can be equipped with my series of robotic arms to realize mobile grabbing, expand the workspace, and enable it to complete more tasks.

Multiple ways to play

- The gamepad control supports multi-robots collaboration in real-time.

3 Product Parameters

| index | parameter |

|---|---|

| name | myAGV |

| size | 311x236x130mm |

| weight | 3.6kg |

| weight capacity | 2kg |

| battery life | 1~1.5h |

| Standby time | 1.5~2h |

| Charging time | 3.5~4h |

| Charging voltage | 12V,2A |

| tire type | Mecanum Wheel |

| Motor type | Hall encoder motor |

| maximum movement speed | 0.9m/s |

| Lidar | 360° omnidirectional radar |

| Recognition range | 8m |

| Built-in controller | raspberry pi 4B 2GB |

| Built-in camera | 500W pixels |

4 product interface

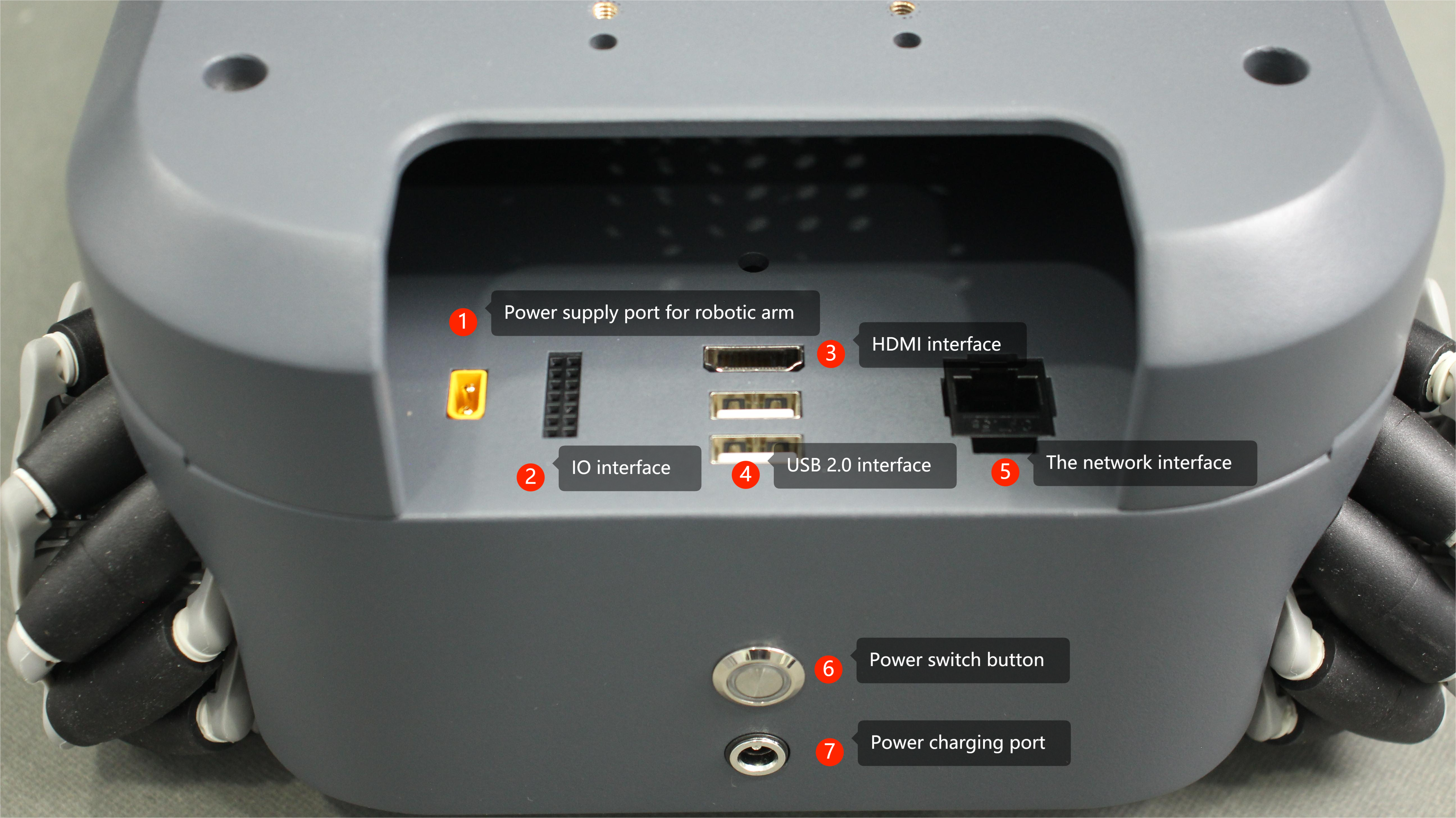

myAGV interface introduction

Figure1-1 myAGV interface introduction

① Power supply port for robotic arm

② IO interface

③ HDMI interface

④ USB 2.0 interface

⑤ The network interface

⑥ Power switch button

⑦ Power charging port

myAGV interface description

A. The power supply interface of the manipulator:Banana plug female, model XT30UPB-F, supplies power to MY series manipulator (12V 5A).

B. IO interface group:All ports are 2.54mm DuPont ports. External 2.54mm Dupont cables can be used. The following table defines the ports.

| Label | Signal | Function | Remarks |

|---|---|---|---|

| 7 | G7 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 8 | G8 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 25 | G25 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 24 | G24 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 23 | G23 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 18 | G18 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| G | GND | GND | |

| 11 | G11 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 9 | G9 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 10 | G10 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 22 | G22 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 27 | G27 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 17 | G17 | 3.3 V-OUT-PNP output /3.3 V-INT input | |

| 3V3 | 3V3 | DC 3.3V |

Table 1-1 I/O interface group description

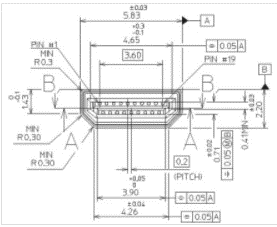

C.HDMI interface:This interface is an HDMI D-type interface (as shown in Figure 1-2) for connecting to the monitor.

Figure 1-2 HDMI D-type interface

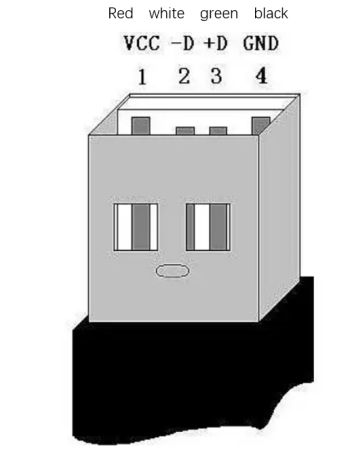

D.USB 2.0 interface:Serial bus standard 2.0 for data connection interface; Users can use the USB interface to copy program files, and can also use the USB interface to connect peripherals such as mouse and keyboard.

Figure 1-3 USB interface definition diagram

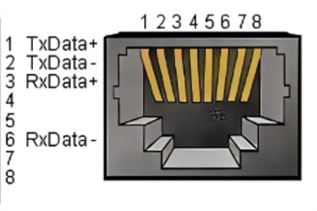

E.The network interface:Network data connection port, the user can use the network interface can be used for PC and robot system communication interaction, can also be used for Ethernet communication with other devices.

Figure 2-2-3 Network interface definition diagram

F.Power switch button:Press down to turn on myAGV.

G.Power charging port:Use DC 2.5*5.5 power port; MyAGV can be charged using the 12V2A DC power adapter provided by the manufacturer.